Technologies

Showing 37-48 of 50 technologies•Clear all filters

Technology database continuously updated • Latest solutions added regularly

Our Curated Technologies

50 technologies

Video Demo Available

Applications:

Warehouses utilizing shuttle-based storage and retrieval systems • Operations deploying fleets of autonomous mobile robots (AMRs) for material movement

Vendor: Movu Robotics

Click to explore full details →

Highly Automated

Video

#WES#Warehouse Execution System#Movu Robotics#Shuttle System#AMR#Robot Orchestration+1

SStorage

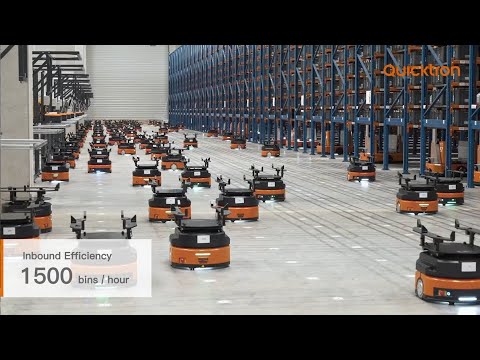

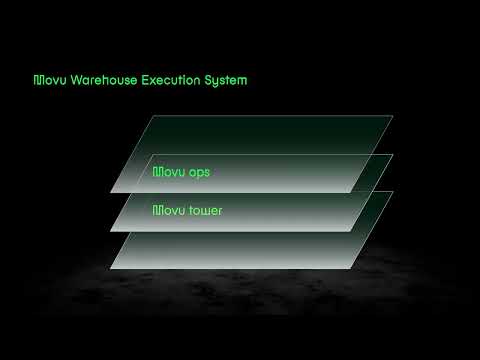

Movu Warehouse Execution System (WES): For Shuttle and AMR Management

BMovu RoboticsAHighly Automated

*Manages, coordinates, and monitors shuttles and autonomous mobile robots (AMRs)

*Modular software architecture with a single interface for customer integration

*Three-level operational structure: Movu Ops (Operations Center), Movu Tower (Planning/Scheduling), Movu Pilot (Robot Driver)

StorageTransportSoftware

Watch Video

Learn More

Video Demo Available

Applications:

E-commerce and micro-fulfillment centers needing faster order shipping • Pharmaceutical and healthcare operations requiring high inventory accuracy

Vendor: Others

Click to explore full details →

Fully automated

Video

#RackBot#Tote ASRS#Goods-to-Person#Shuttle System#Micro-Fulfillment#Warehouse Automation

SStorage

RackBot™ Tote ASRS: Flexible Goods-to-Person Automation

BOthersAFully automated

*Works with existing standard tote racking (no need for complete infrastructure rebuild)

*Modular design providing ultimate layout flexibility

*Tote-based Goods-to-Person Automated Storage and Retrieval System (ASRS)

StoragePicking

Watch Video

Learn More

Video Demo Available

Applications:

Machine tending (loading/unloading CNC machines, turning lathes, packaging machines) • Transfer operations between machines or from machines to human operators

Vendor: Others

Click to explore full details →

Fully automated

Video

#Robsen Robotics#FANUC#Milvus Robotics#Cobot#AMR#Collaborative Robot#Machine Tending#3D Vision

MTransport

Cobot-AMR Integration: FANUC Cobot & Milvus AMR for Flexible Automation

BOthersAFully automated

*Integration of a FANUC CRX-10iA/L collaborative robot with a Milvus AMR Robot SEIT 300s

*Cobot optionally equipped with a 3D vision sensor for accurate object identification and positioning

*AMR can easily navigate complex environments without cables, magnets, lights, or markers

TransportPicking

Watch Video

Learn More

Video Demo Available

Applications:

Collecting parts or kits from multiple workstations for assembly or order consolidation • Automated material handling in flexible manufacturing cells

Vendor: Others

Click to explore full details →

Fully automated

Video

#TM Robot#AI Cobot#AMR#Collaborative Robot#Material Collection#Multi-Station

MTransport

TM AI Cobot with AMR: Automated Multi-Station Goods Collection

BOthersAFully automated

*Integration of a TM AI Cobot (collaborative robot) with an Autonomous Mobile Robot (AMR)

*Automates the collection of goods from multiple stations

*Combines robotic manipulation with autonomous mobility

TransportPicking

Watch Video

Learn More

Video Demo Available

Applications:

Growing enterprises looking to modernize warehouse operations and hone competitive advantages • Warehouses relying on manual case handling for inbound and outbound processes

Vendor: Hai Robotics

Click to explore full details →

Fully automated

Video

#Hai Robotics#HaiPick#ACR#Goods-to-Person#Storage Density#Warehouse Modernization

MTransport

Goods-to-Person ACR Solution for Warehouse Modernization

BHai RoboticsAFully automated

*Powered by pioneer Autonomous Case-handling Mobile Robot (ACR) technology

*Designed for superior flexibility and scalability

*Centralizes and digitizes data analysis for management

TransportPicking

Watch Video

Learn More

Video Demo Available

Applications:

E-commerce fulfillment centers facing demands for faster 'click-to-door' delivery • Operations needing to handle a wide variety of products and dynamic order batches

Vendor: GreyOrange

Click to explore full details →

Fully automated

Video

#GreyOrange#Ranger GTP#Goods-to-Person#AMR#E-commerce Fulfillment#Flexible Automation

MTransport

GTP: Decision-Driven Goods-to-Person AMR

BGreyOrangeAFully automated

*Decision-driven science and robotics

*Autonomous transport of inventory to stationary workers for picking and packing

*Designed for flexibility and speed in fulfillment

TransportPicking

Watch Video

Learn More

Video Demo Available

Applications:

Autonomous transport of materials between production lines and warehouses • Moving goods across large facilities spanning indoor workshops and outdoor yards

Vendor: VisionNav Robotics

Click to explore full details →

Fully automated

Video

#AMR#AGV#Tugger#Autonomous Towing#VisionNav

RTransport

AMR/AGV Tuggers: Autonomous Towing for Trailers and Trolleys

B VisionNav RoboticsAFully automated

*Autonomous and safe towing of trailers and trolleys

*Multiple capacity models: 6,000 kg, 10,000 kg, and 20,000 kg

*CE Certified models (VNQ100 & VNQ200) for regulated environments

Transport

Watch Video

Learn More

Video Demo Available

Applications:

High-density storage applications where building height is a key advantage • Operations requiring flexible retrieval patterns beyond fixed-aisle systems

Vendor: Jiangsu NOVA Intelligent Logistics Equipment

Click to explore full details →

Video

#Four Way Shuttle#Shuttle System#AS/RS#High-Density Storage#Warehouse Automation#Intralogistics

SStorage

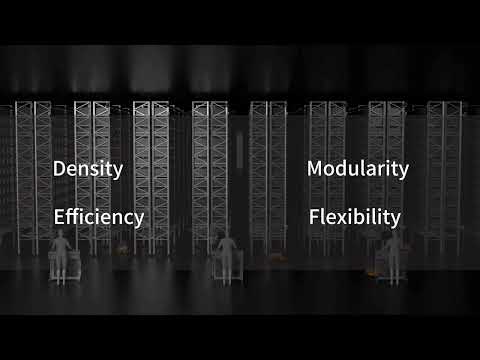

Four Way Shuttle System: Flexible High-Density AS/RS

BJiangsu NOVA Intelligent Logistics Equipment

*Utilizes four-way entry shuttles capable of moving in four directions within the rack grid

*Enables flexible picking and transport of goods around the racks

*Shuttles can reach any position in the vertical warehouse, not limited by fixed lanes

StorageTransportPickingSoftware

Watch Video

Learn More