Large-Scale AMR Sorting System for E-commerce Fulfillment

⚡Quick Facts

Technology Performance Metrics

⭐Key Features

✨Benefits

🎯Applications

📝Detailed Information

Technology Overview

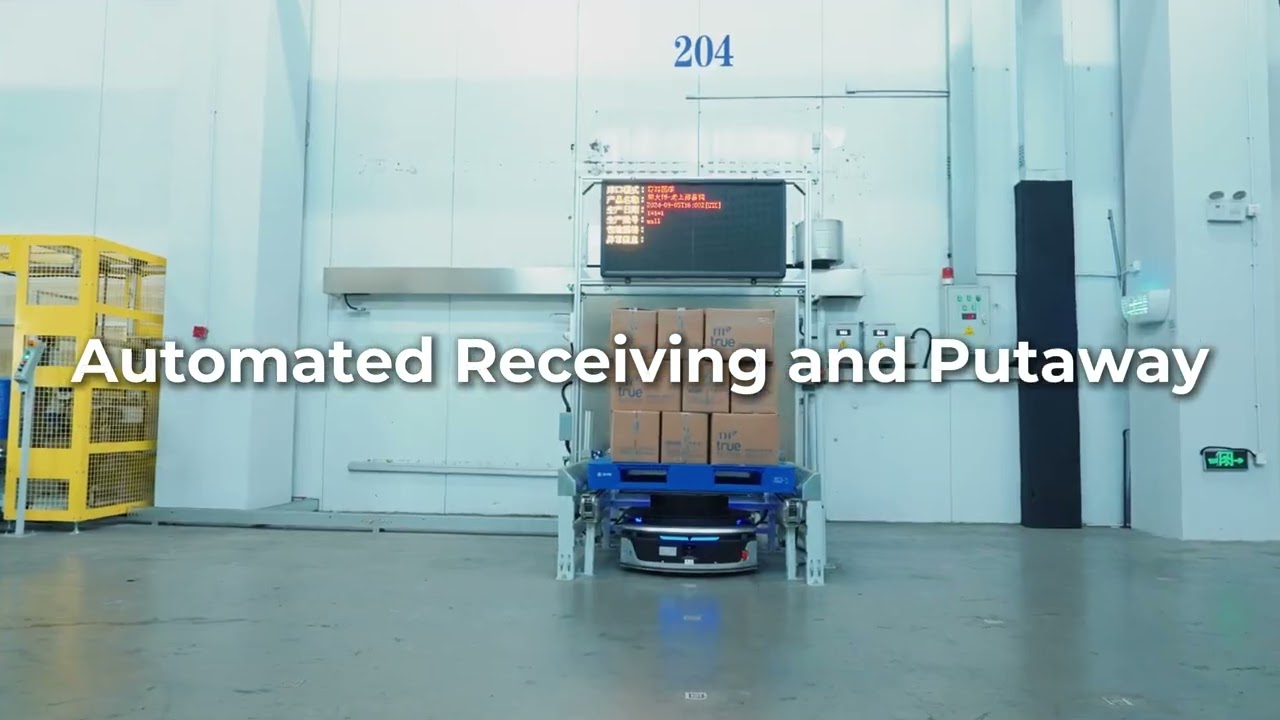

Geek+, a leading global provider of autonomous mobile robots (AMRs), has successfully deployed what is described as the first large-scale AMR sorting system specifically for e-commerce fulfillment. This implementation was carried out for Banggood, a major global e-commerce platform. The system is designed to address the immense logistical challenges of cross-border e-commerce, supporting Banggood's operations across 37 international warehouses that ship to customers in over 200 countries. Unlike traditional fixed conveyor sorters, this AMR-based system leverages fleets of mobile robots to dynamically sort parcels. This approach is particularly suited to the variable volumes and flexible layouts of e-commerce fulfillment, providing a scalable and adaptable sorting backbone for a rapidly growing global business.

How It Works

Core Principles

The core principle is Scalable, Mobile Parcel Sortation. Instead of moving parcels on a fixed conveyor past static induction and diverts, this system uses AMRs as the primary sortation medium. Parcels are placed onto AMRs (or into containers carried by AMRs). Each robot is assigned a specific destination (e.g., a outbound chute for a particular country or postal route) and navigates autonomously through the sortation floor to deliver its parcel, after which it returns for another assignment. The system scales by adding more robots.

Key Features & Capabilities

Large-Scale, Network-Wide Deployment is its defining characteristic. Implementing a consistent AMR sorting solution across 37 international warehouses demonstrates the system's replicability and ability to standardize operations in a global network, which is a significant advantage for international e-commerce players.

Inherent Scalability and Flexibility of AMRs is crucial for e-commerce. The sorting capacity can be adjusted by modifying the size of the AMR fleet and the layout of destinations, allowing Banggood to efficiently handle peak season surges and ongoing growth without massive fixed infrastructure changes.

Adaptability to Cross-Border Logistics Complexity is a key requirement. The system software must manage sortation based on complex rules involving destination countries, customs, couriers, and service levels, integrating this intelligence into the real-time robot dispatch logic.

Advantages & Benefits

The primary benefit is Meeting the Demands of Global E-Commerce Growth. For a company like Banggood, shipping to 200+ countries, a flexible, accurate, and scalable sorting system is essential to maintain service levels and manage costs as volume increases.

It provides Operational Consistency Across a Global Network. Deploying the same Geek+ system in multiple warehouses simplifies training, maintenance, and process management, creating efficiency gains at the corporate level.

The system offers Reduced Reliance on Fixed Infrastructure. Compared to installing large conveyor sorters in 37 locations, an AMR-based system likely requires less permanent installation and can be more easily reconfigured, offering potential savings in capital expenditure and facility flexibility.

It enhances Sortation Accuracy and Traceability. Automated scan-and-sort processes minimize manual handling errors. The digital nature of the system provides complete traceability for each parcel through the sortation process, which is vital for cross-border shipping compliance and customer service.

Implementation Considerations

Global Roll-Out Coordination and Local Adaptation is a monumental task. While the technology is consistent, each of the 37 warehouses may have different layouts, local IT systems, and operational nuances. Successful implementation requires meticulous project management and potentially some site-specific customization.

Integration with Global E-Commerce Systems is complex. The sortation system must seamlessly connect with Banggood's order management, warehouse management, and global shipping carrier systems to receive accurate sortation instructions in real-time.

Maintaining System Performance at Scale is an ongoing challenge. Managing a fleet of hundreds or thousands of AMRs across multiple sites requires robust fleet management software, reliable network infrastructure, and efficient local operational procedures to prevent bottlenecks and ensure high throughput.

Conclusion

Geek+'s large-scale AMR sorting system implementation for Banggood represents a significant milestone in the application of mobile robotics to global e-commerce logistics. It demonstrates that AMR technology is mature and reliable enough to form the core sortation infrastructure for a major international retailer. This solution is ideal for e-commerce businesses with vast scale, global reach, and a need for sorting flexibility to handle volatile demand and complex shipping rules. The success of this deployment suggests that AMR-based sorting is a viable and competitive alternative to traditional systems, particularly where scalability, network consistency, and reduced fixed investment are priorities. For other global e-commerce players looking to modernize and scale their sortation capabilities, Geek+'s proven large-scale approach offers a compelling and innovative model.

📦Related Projects

JJCL Multi-Zone Cold Chain Automation

World's first multi-zone pallet-handling system for deep-freeze automation, automating frozen-to-chilled zone movement with zero manual transfers.

X-step Smart Warehouse

X-step implemented Geek+ Robo shuttle tote-to-person picking solution to handle international expansion and seasonal demand fluctuations in sports apparel industry.

International 3PL E-commerce Warehouse with RoboShuttle

A 3PL cross-border e-commerce warehouse utilizing Geekplus RoboShuttle, the industry's tallest mobile robot, achieving 500+ units per hour picking efficiency with maximum vertical space utilization.