Pallet Flow Racking

Pallet flow racking uses gravity-fed roller or wheel tracks to automatically move pallets from the loading side to the picking face, ensuring perfect FIFO rotation for date-sensitive products.

Pallet Flow Racking (Gravity Flow) Overview

System Features

- •Gravity-PoweredAutomatic flow

- •Perfect FIFOFirst-in-first-out

- •Separate AislesLoad back, pick front

- •Dynamic StorageAuto replenishment

Track Systems

- •Roller TracksFull-width rollers

- •Wheel TracksMultiple wheel lanes

- •Speed ControllersRegulate flow

- •3-5% SlopeOptimal gradient

Applications

- •Food and BeveragePerishable goods

- •PharmaceuticalDate-sensitive

- •Cross-DockingFlow-through

- •ManufacturingProduction feeding

Key Benefits

- •Guaranteed FIFOPerfect rotation

- •40-60% FasterPicking speed

- •Reduced TravelLess forklift time

- •Auto ReplenishmentContinuous flow

Configuration

- •Lane Depth: 3-20+6-12 typical

- •Height: Up to 25ftMultiple levels

- •Load: 2,000-3,500 lbsPer pallet

- •Utilization: 65-75%Space efficiency

Future Trends

- •IoT MonitoringReal-time tracking

- •Smart ControlsAdaptive braking

- •AGV IntegrationAutomated loading

- •Predictive AnalyticsOptimize flow

How Pallet Flow Racking Works

The core mechanism consists of inclined roller tracks or wheel lanes mounted within a racking structure, typically sloped at 3-5% grade to provide sufficient gravity force for pallet movement without excessive speed. Speed controllers or braking systems regulate pallet velocity as they flow down the lanes, preventing pallets from colliding or moving too quickly. The controllers use various technologies including magnetic brakes, roller brakes, or mechanical speed reducers that automatically engage based on pallet weight and position, ensuring controlled, safe movement throughout the flow process.

Lane configuration typically ranges from 3-20+ pallets deep, with depth determined by product velocity, pallet quantities per SKU, and available floor space. Each lane is dedicated to a single SKU to maintain FIFO integrity, with pallets flowing continuously from the loading side to the picking face as positions are depleted. The loading side (rear) is accessed by forklifts or other material handling equipment that place pallets onto the elevated entry point, while the picking face (front) provides easy access for order fulfillment operations. This separation of loading and picking activities improves operational efficiency by eliminating traffic conflicts and enabling simultaneous replenishment and picking operations.

Entry and exit mechanisms ensure smooth pallet transitions onto and off the flow tracks. The entry point typically includes a loading ramp or transition section that guides pallets from the forklift onto the roller tracks, with proper alignment critical for preventing jams or damage. The exit point at the picking face includes pallet stops or separators that hold pallets in position for retrieval while allowing the next pallet to advance when the front position is emptied. Some systems use automatic indexing that advances pallets immediately when the front position is cleared, while others require manual release by the operator to control pallet presentation.

Track types vary based on pallet weight, lane length, and operational requirements. Full roller tracks provide the smoothest flow and lowest friction but represent the highest cost option, suitable for heavy pallets or long lanes. Wheel tracks use spaced wheels instead of continuous rollers, reducing cost while maintaining adequate flow characteristics for most applications. Hybrid systems combine rollers in critical areas (entry, exit, curves) with wheels in straight sections, balancing performance and cost. The track selection must account for pallet bottom configuration, as pallets with damaged or non-standard bottoms may not flow properly on some track types.

Key Benefits

The primary advantage of pallet flow racking is automatic FIFO rotation that ensures the oldest product is always picked first without requiring operator discipline or system controls. This automatic rotation is critical for perishable goods, date-coded products, and time-sensitive inventory where product freshness and regulatory compliance depend on proper rotation. Unlike selective racking where operators must manually select the correct pallet or drive-in systems that enforce LIFO rotation, pallet flow physically ensures FIFO through its gravity-fed design, eliminating rotation errors and reducing product obsolescence.

High throughput results from the separation of loading and picking activities, enabling simultaneous operations without traffic conflicts. Replenishment occurs at the rear of the system while picking happens at the front, allowing both activities to proceed independently and maximizing productivity. The continuous flow of pallets to the picking face eliminates the need for operators to search for products or travel into storage areas, reducing pick times and improving order fulfillment efficiency. Operations with high pallet movement volumes (100+ pallets per day per lane) achieve significant productivity gains compared to selective racking.

Space utilization of 65-75% provides good density while maintaining excellent accessibility at the picking face. While not as dense as drive-in systems (75-85%), pallet flow offers significantly better throughput and guaranteed FIFO rotation. The reduced travel time for picking operations often enables facilities to achieve higher overall productivity in less floor space compared to selective racking, even though the raw storage density is similar. The elimination of aisles between lanes (except at loading and picking faces) contributes to the improved space efficiency.

Labor efficiency improves through the automatic pallet presentation at the picking face and the elimination of product search time. Operators always know exactly where to find products—at the front of each lane—without checking locations or traveling through storage areas. The ergonomic benefits of having products automatically advance to accessible positions reduce operator fatigue and improve picking accuracy. Many operations achieve 20-40% productivity improvements in picking operations compared to selective racking, particularly for high-velocity items.

Common Applications

Food and beverage distribution represents the largest application for pallet flow racking, where FIFO rotation is essential for managing date-coded products and ensuring product freshness. Dairy products, fresh produce, beverages, and packaged foods all benefit from the automatic rotation that prevents older products from being bypassed. The high throughput supports the rapid order fulfillment required in food distribution, while the space efficiency helps manage the large inventories typical of these operations. Many food distributors use pallet flow for their highest-velocity items combined with selective racking for slower-moving products.

Pharmaceutical and healthcare operations use pallet flow for medications, medical supplies, and other products where lot traceability and expiration date management are critical for regulatory compliance and patient safety. The automatic FIFO rotation ensures that products are used before expiration, reducing waste and supporting compliance with FDA and other regulatory requirements. The separation of replenishment and picking also supports clean room protocols by minimizing traffic and contamination risks in picking areas.

Retail distribution centers leverage pallet flow for fast-moving consumer goods that require rapid replenishment to store locations. The high throughput and automatic FIFO rotation support the quick order turnaround required in retail supply chains, while the space efficiency enables facilities to stock adequate inventory in constrained urban locations. Cross-docking operations particularly benefit from pallet flow, as products can flow directly from receiving to shipping with minimal handling and perfect rotation control.

Manufacturing operations use pallet flow for production line feeding, where components and materials must be delivered to assembly areas in proper sequence. The automatic FIFO ensures that materials are consumed in the correct order, supporting quality control and reducing the risk of using outdated components. The continuous replenishment from the rear allows materials handlers to restock lanes without disrupting production operations, maintaining smooth material flow to assembly lines.

Implementation Considerations

Successful pallet flow implementation requires careful evaluation of product characteristics to ensure compatibility with gravity flow systems. Pallet condition is critical—damaged pallets with broken boards, protruding nails, or non-standard dimensions may jam in the lanes or damage the track system. Operations should implement pallet quality standards and inspection processes to ensure only suitable pallets enter the flow system. Load stability must be adequate to withstand the movement and potential impacts during flow, requiring proper stretch wrapping or other load containment methods.

Lane depth optimization balances storage capacity against operational efficiency and system cost. Deeper lanes (10-20+ pallets) maximize storage density and reduce the frequency of replenishment, but increase system cost and may create longer flow times that could affect product rotation in some applications. Shallower lanes (3-6 pallets) reduce cost and improve responsiveness but require more frequent replenishment. Most operations find optimal performance with 6-10 pallet depths that balance these factors, though specific requirements vary based on product velocity and operational characteristics.

Slope and speed control must be properly engineered to ensure safe, reliable operation. Insufficient slope results in pallets stalling or requiring manual intervention to advance, while excessive slope creates high speeds that can damage products or create safety hazards. The speed controllers must be properly sized and positioned based on pallet weight, lane length, and slope to maintain controlled movement throughout the flow process. Professional engineering and installation are essential for achieving proper performance and safety.

Building integration requires adequate ceiling height to accommodate the elevated loading side of the system. The rear elevation is typically 12-18 inches higher than the front, requiring either raised loading platforms or adequate ceiling clearance for forklifts to place pallets at the elevated entry point. Some facilities use mezzanines or elevated platforms for loading operations, while others rely on reach trucks or order pickers that can place pallets at height. The facility layout must provide access to both loading and picking faces, typically requiring aisles on opposite sides of the flow system.

Best Practices

Product velocity analysis should guide lane assignments to maximize system utilization and operational efficiency. Highest-velocity items should occupy the most accessible lanes near shipping areas to minimize travel distance and maximize throughput. Medium-velocity products can occupy interior lanes where slightly longer access times have less operational impact. The number of lanes per SKU should match product velocity and pallet quantities to maintain adequate flow without excessive replenishment frequency or lane depletion.

Pallet quality management programs are essential for preventing jams and maintaining system reliability. Incoming pallet inspection should identify and reject damaged pallets before they enter the flow system. Pallet repair or replacement programs ensure that only suitable pallets are used for products stored in flow lanes. Some operations invest in standardized plastic pallets or high-quality wood pallets specifically for flow racking applications, accepting the higher cost to ensure reliable operation and reduce maintenance requirements.

Regular maintenance includes inspecting and cleaning roller tracks, checking speed controller operation, verifying proper slope and alignment, and replacing worn components. Monthly inspections should check for debris accumulation, damaged rollers or wheels, and proper pallet flow. Quarterly maintenance should include lubrication of moving parts, speed controller adjustment, and structural integrity checks. Annual professional inspections provide comprehensive assessments and identify potential issues before they cause operational disruptions.

Load containment standards ensure that products remain stable during flow and don't shift or fall during movement. Stretch wrapping specifications should provide adequate containment for the movement and potential impacts during flow. Load height limits prevent top-heavy loads that could tip during movement. Weight distribution requirements ensure that loads don't shift during flow, which could cause jams or damage. Clear standards and operator training support consistent load quality that enables reliable flow operation.

Measuring Success

Key performance indicators for pallet flow racking include flow reliability (percentage of pallets flowing without intervention), pick productivity (pallets picked per hour), FIFO compliance (100% target), and system uptime (target 98%+). These metrics help operations evaluate whether the system delivers expected rotation control and productivity benefits while maintaining reliable operation. Tracking jam frequency and maintenance requirements identifies opportunities for improvement in pallet quality, load containment, or system maintenance.

Return on investment typically materializes over 3-5 years through improved picking productivity, reduced product obsolescence, better space utilization, and lower labor costs. The productivity improvements of 20-40% in picking operations often provide the largest economic benefit, particularly for high-velocity items. Reduced product waste from better rotation control delivers ongoing savings, especially valuable for perishable goods or products with limited shelf lives. The space efficiency enables facilities to store more inventory in the same footprint or defer facility expansion.

Product rotation performance should show zero or near-zero instances of expired or obsolete products being discovered in flow lanes, validating that the automatic FIFO rotation is working as designed. Comparing product waste rates before and after pallet flow implementation quantifies the rotation benefits. Lot traceability should improve as the system enforces proper rotation and simplifies tracking of which lots are in which lanes.

By implementing pallet flow racking with careful attention to product characteristics, lane configuration, and maintenance practices, facilities can achieve automatic FIFO rotation, high throughput, and improved labor efficiency for their highest-velocity, most date-sensitive products. The proven technology and significant operational benefits make pallet flow a valuable tool for food distribution, pharmaceuticals, retail, and manufacturing operations where product rotation and picking efficiency are critical.

🔧Related Technologies (6)

Live Storage Systems: Gravity-Flow High-Density Storage

byAR Racking

Pallet Flow Racking: High-Density FIFO Storage Solution

byOthers

Pallet Flow Racking: High-Density FIFO Storage System

byAtlantic Rack

Pallet Shuttle: Semi-Automated High-Density Storage System

byMecalux

Pallet Shuttle System: High-Density Semi-Automated Storage

byDexion - Gonvarri Material Handling

Dark Warehouse: Fully Automated Warehouse Operations

byAddverb

📚Related Storage Topics

About This Topic

📁Related Projects(6)

Bastian Solutions Corporate Profile: Toyota Advanced Logistics

Bastian Solutions

Addverb 3PL Omnichannel Fulfillment Center

Addverb

MULTIFLEX Pallet Warehouse: High-Density Frozen Storage

MFI (implied contractor)

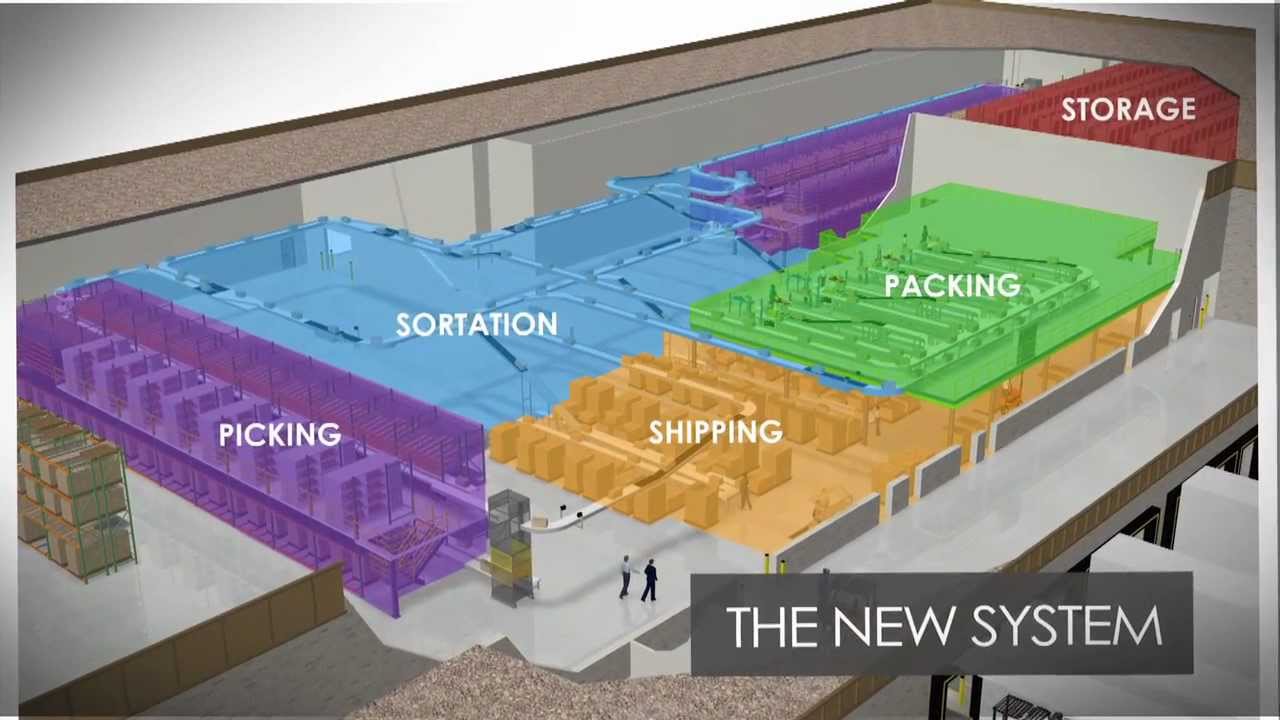

Amway Midwest Regional Service Center, Ada

Bastian Solutions

Roche Diagnostics Indianapolis Distribution Center

Bastian Solutions

SEW-EURODRIVE Bruchsal Electronics Plant

GEBHARDT Intralogistics Group

🏢Related Suppliers(3)

Exotec

Elegant Solutions to Simplify Logistic Operations

Symbotic

AI-Powered Warehouse Automation Systems

Boston Dynamics

Advanced robotics company developing mobile robots for industrial automation and logistics applications.