Pallet Racking

Pallet racking systems are structural storage solutions that hold palletized goods in horizontal rows with multiple levels, forming the backbone of warehouse operations by maximizing vertical space while maintaining direct access to inventory.

Pallet Racking Systems Overview

Racking Types

- •Selective Racking100% pallet access

- •Drive-In/ThroughHigh-density storage

- •Push-BackLIFO, 2-6 deep

- •Pallet FlowFIFO, gravity-fed

Applications

- •Distribution CentersGeneral warehousing

- •ManufacturingRaw materials & WIP

- •Food & BeverageCold storage

- •RetailFast-moving goods

Key Benefits

- •Cost-Effective$50-350 per position

- •Flexible ConfigurationEasy to reconfigure

- •ScalableExpand as needed

- •Universal CompatibilityStandard forklifts

Space Utilization

- •Selective: 40-50%Full accessibility

- •Drive-In: 75-85%Maximum density

- •Push-Back: 60-70%Medium density

- •Pallet Flow: 65-75%FIFO operations

Investment

- •Selective: $50-100Per pallet position

- •Drive-In: $75-125Per pallet position

- •Push-Back: $150-250Per pallet position

- •ROI: Immediate-2 yearsFast payback

Future Trends

- •Smart SensorsIoT tracking

- •Hybrid AutomationAGV integration

- •Sustainable MaterialsRecycled steel

- •Safety FeaturesCollision detection

How Pallet Racking Works

The fundamental design of pallet racking consists of vertical frames (uprights) connected by horizontal load beams that support pallets at various heights. The frames are anchored to the warehouse floor and braced for stability, while the beams are adjustable to accommodate different pallet heights and product dimensions. This modular construction allows facilities to configure racking layouts that match their specific operational requirements, inventory characteristics, and available space. The most common configuration, selective pallet racking, provides direct access to every pallet position from the aisle, enabling operators to retrieve any pallet without moving others—a critical capability for operations managing diverse product mixes or requiring strict inventory rotation control.

Load capacity varies by system design and component specifications, with typical pallet positions supporting 2,000-5,000 pounds per pallet. The beams are rated for specific weight limits, and facilities must ensure that actual loads never exceed these ratings to maintain structural integrity and safety. Beam levels can be adjusted vertically on the frames, typically in 2-inch increments, allowing operators to optimize space utilization as product mix changes over time. This adjustability represents a key advantage over fixed shelving or block stacking, where changing product dimensions require significant reconfiguration or wasted vertical space.

Aisle widths are determined by the type of material handling equipment used to access the racking. Counterbalance forklifts require aisles of 10-12 feet to maneuver safely, while reach trucks can operate in narrower aisles of 8-10 feet by extending their forks forward rather than turning the entire vehicle. Very narrow aisle (VNA) systems use specialized wire-guided trucks that operate in aisles as narrow as 5-7 feet, maximizing storage density while maintaining full pallet selectivity. The choice of aisle width represents a fundamental trade-off between storage density and operational flexibility—narrower aisles store more pallets in the same footprint but require specialized equipment and may reduce throughput compared to wider aisles that allow faster forklift movement.

Key Benefits

The primary advantage of pallet racking is cost-effectiveness relative to storage capacity provided. With costs typically ranging from $50-150 per pallet position for standard selective racking, facilities can implement thousands of pallet positions for a fraction of the investment required for automated systems. This low capital requirement makes racking accessible to small and medium-sized operations while providing large facilities with economical capacity expansion options. The immediate implementation timeline—typically 2-4 weeks from order to operational—enables facilities to respond quickly to growth or seasonal demand without lengthy planning and integration cycles.

Flexibility and reconfigurability represent major operational advantages. Beam levels can be adjusted to accommodate changing product dimensions, entire sections can be reconfigured to support different storage strategies, and the modular design allows incremental expansion as needs grow. This adaptability is particularly valuable for operations with evolving product mixes, seasonal variations, or uncertain growth trajectories. Unlike automated systems that lock facilities into specific configurations and operational patterns, pallet racking adapts to changing business requirements without major reinvestment or disruption.

Full pallet selectivity in standard selective racking configurations enables precise inventory control and rotation. Every pallet is directly accessible without moving other pallets, supporting FIFO (first-in, first-out) or LIFO (last-in, first-out) rotation strategies as needed. This accessibility is critical for operations managing perishable goods, date-sensitive products, or diverse SKU mixes where specific pallets must be retrieved on demand. The ability to access any pallet at any time also simplifies inventory management, cycle counting, and quality control processes compared to high-density systems where pallets are stored multiple positions deep.

Space utilization improves dramatically compared to floor stacking, with racking systems typically achieving 40-50% utilization of building volume in selective configurations and up to 85% in high-density drive-in systems. By maximizing vertical space—often reaching heights of 30-40 feet or more—facilities can store significantly more inventory in the same footprint, reducing real estate costs and enabling operations to defer or avoid costly facility expansions. The organized structure also improves safety by preventing unstable pallet stacks and creating clear traffic lanes for material handling equipment.

Common Applications

Distribution and logistics operations represent the largest application for pallet racking, with facilities managing 500-10,000+ SKUs requiring the full selectivity and flexibility that standard selective racking provides. These operations typically handle diverse product mixes with varying pallet quantities per SKU, frequent inventory turnover, and multiple customer orders daily. The ability to access any pallet immediately supports efficient order fulfillment while the adjustable configuration accommodates changing product assortments without major reconfiguration. Many distribution centers combine selective racking for fast-moving items with higher-density systems like drive-in or push-back racking for slower-moving or bulk storage items.

Manufacturing facilities use pallet racking for raw materials storage, work-in-process inventory, and finished goods staging. Raw materials often require high-density storage using drive-in or push-back systems to maximize space efficiency for bulk quantities, while component and parts inventory benefits from selective racking that provides easy access for production line feeding. Finished goods staging areas typically use selective or push-back racking to organize products awaiting shipment while maintaining flexibility for varying production volumes and customer order patterns.

Food and beverage operations require strict FIFO rotation to manage date-coded products and ensure product freshness. Pallet flow racking (gravity flow systems) provides automatic FIFO rotation by allowing pallets to flow from the loading side to the picking face on roller or wheel tracks, ensuring that the oldest product is always picked first. This configuration is particularly valuable for perishable goods, dairy products, and beverages where product rotation is critical for quality and regulatory compliance. Cold storage facilities often use high-density drive-in racking to maximize space efficiency in expensive temperature-controlled environments while managing energy costs.

Retail and e-commerce operations leverage pallet racking for seasonal inventory management, fast-moving consumer goods, and order fulfillment operations. The flexibility to quickly reconfigure racking supports seasonal peaks and changing product assortments, while selective racking enables efficient picking operations for high-velocity items. Many operations use a combination of racking types—selective for active picking, push-back for seasonal overflow, and pallet flow for high-velocity replenishment—to optimize space utilization and operational efficiency across varying demand patterns.

Implementation Considerations

Successful pallet racking implementation begins with thorough space analysis to determine optimal racking type, layout, and configuration. Facilities must evaluate their SKU count and variety, pallets per SKU, inventory rotation requirements, available ceiling height, floor space constraints, and budget limitations to select the appropriate racking system. Operations with high SKU counts and diverse product mixes typically benefit from selective racking, while those with low SKU counts and large quantities per SKU can achieve better space utilization with high-density systems like drive-in or push-back racking.

Floor load capacity must be verified before installation, as concentrated racking loads can exceed the capacity of some warehouse floors. Typical warehouse floors support 4,000-6,000 PSF (pounds per square foot), but older facilities or those not originally designed for racking may require floor reinforcement or load distribution measures. A structural engineer should evaluate floor capacity and recommend any necessary remediation before racking installation to prevent costly floor damage or safety issues. The floor should also be reasonably level and smooth to ensure stable racking installation and safe forklift operation.

Seismic requirements vary by geographic location and must be addressed during design and installation. Facilities in earthquake-prone areas require seismic-rated racking components, proper bracing and anchoring, and engineering calculations that account for lateral forces during seismic events. Working with seismic-certified rack manufacturers and following local building codes ensures compliance and safety. Regular inspections and maintenance become even more critical in seismic zones to identify and repair any damage that could compromise structural integrity during an earthquake.

Material handling equipment compatibility must be considered when selecting racking type and aisle widths. The facility's existing or planned forklift fleet determines minimum aisle widths and maximum reach heights. Counterbalance forklifts offer the most flexibility and can operate outdoors or in loading areas, but require wider aisles that reduce storage density. Reach trucks enable narrower aisles and higher reach but are limited to smooth indoor floors. VNA trucks maximize storage density but require wire guidance systems, smooth floors, and represent a significant equipment investment. The choice of equipment and aisle width represents a fundamental trade-off between storage density, operational flexibility, and capital investment.

Best Practices

Layout optimization should consider traffic flow patterns, product velocity, and operational efficiency. Fast-moving items should be positioned closest to shipping areas to minimize travel distance, while slower-moving products can be stored in more remote locations. Organizing products by velocity, customer, or order frequency reduces picking time and improves throughput. Many facilities use ABC analysis to classify inventory by movement velocity and assign storage locations accordingly, with A items (highest velocity) in the most accessible locations and C items (lowest velocity) in less convenient positions.

Safety features are essential for protecting both personnel and racking structure. Column protectors shield upright frames from forklift impacts, end-of-aisle guards prevent vehicles from striking rack ends, and row spacers maintain proper clearances between back-to-back rack rows. Load beam safety clips prevent beams from being accidentally dislodged, while proper signage and labeling communicate load capacities, aisle designations, and safety requirements. Regular operator training on safe loading practices, speed limits, and proper equipment operation reduces accident risks and extends racking lifespan.

Regular inspections identify damage or deterioration before it compromises safety. Monthly visual inspections by facility personnel should check for bent or damaged components, missing safety clips, overloaded beams, and improper pallet placement. Annual inspections by qualified rack safety professionals provide more thorough assessments and ensure compliance with industry standards like RMI (Rack Manufacturers Institute) guidelines. Any damaged components should be repaired or replaced immediately, as compromised structural integrity can lead to catastrophic rack failures.

Capacity management ensures that actual loads never exceed rated capacities. Each beam level should be clearly labeled with its maximum load capacity, and operators should be trained to respect these limits. Facilities should maintain documentation of rack specifications, load ratings, and configuration changes to support ongoing safety management. Overloading is a leading cause of rack failures and can result in serious injuries, product damage, and facility disruption.

Measuring Success

Key performance indicators for pallet racking systems include space utilization (percentage of building volume used for storage), storage density (pallets stored per square foot), accessibility (percentage of pallets directly accessible), and cost per pallet position (total investment divided by pallet positions). These metrics help facilities evaluate whether their racking configuration optimally balances density, accessibility, and cost for their specific operational requirements.

Return on investment for pallet racking is typically immediate to 2 years, driven by increased storage capacity in existing facilities, deferred facility expansion costs, and improved operational efficiency. The ability to store 40-85% more inventory in the same footprint compared to floor stacking often eliminates the need for additional warehouse space, delivering significant real estate cost savings. Improved organization and accessibility also reduce labor costs for putaway and retrieval operations while minimizing product damage from unstable floor stacks.

Safety performance should show reduced accident rates, product damage, and facility damage compared to floor stacking or poorly organized storage. Tracking forklift incidents, rack damage reports, and near-miss events helps identify areas for improvement in operator training, traffic management, or rack protection. The structured environment that racking provides typically improves safety significantly compared to unorganized floor storage where unstable stacks and congested traffic create hazards.

By implementing pallet racking with careful attention to system selection, layout optimization, and safety management, facilities can create efficient, flexible storage systems that support growth, adapt to changing requirements, and deliver strong returns on investment for decades. The proven technology, universal compatibility, and low capital requirements ensure pallet racking remains the foundation of warehouse storage across industries and facility sizes.

🔧Related Technologies (6)

MIX: All-round Goods-to-Person Picking Solution

byMushiny

Autopicker: AI-Powered Mobile Picking Robot

byBrightpick

Modular Pallet Conveyor Platform (MPP): Flexible Automation Basis

byInterroll

Pallet Racking Systems: Configurable Warehouse Storage Solutions

byDexion - Gonvarri Material Handling

Selective Pallet Racking: Universal Warehouse Storage System

byOthers

Pallet Racking Installation: Organizing Warehouse Storage

byOthers

📚Related Storage Topics

About This Topic

📁Related Projects(6)

MULTIFLEX Pallet Warehouse: High-Density Frozen Storage

MFI (implied contractor)

Bastian Solutions Corporate Profile: Toyota Advanced Logistics

Bastian Solutions

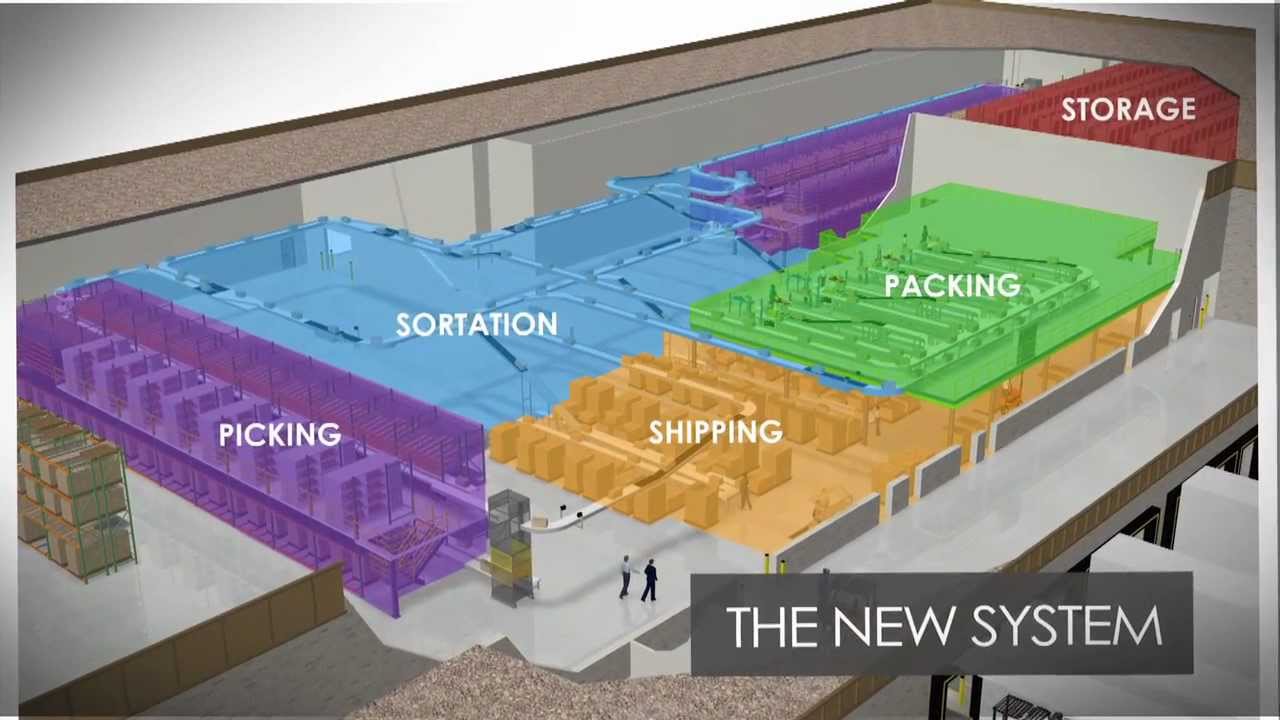

Amway Midwest Regional Service Center, Ada

Bastian Solutions

Roche Diagnostics Indianapolis Distribution Center

Bastian Solutions

SEW-EURODRIVE Bruchsal Electronics Plant

GEBHARDT Intralogistics Group

ASKO Oslofjord Automated Distribution Center

SSI Schaefer

🏢Related Suppliers(3)

Exotec

Elegant Solutions to Simplify Logistic Operations

Symbotic

AI-Powered Warehouse Automation Systems

Boston Dynamics

Advanced robotics company developing mobile robots for industrial automation and logistics applications.