Bastian Solutions Corporate Profile: Toyota Advanced Logistics

⭐Key Features

- •A Toyota Advanced Logistics company, part of the global Toyota family since 2017

- •Employs the Toyota Production System concept of 'Jidoka' (intelligent automation that creates value)

- •Client-focused culture built on integrity, relationships, innovation, diversity, and continuous improvement

- •Offers end-to-end supply chain integration from consulting to implementation

- •Provides a comprehensive portfolio of automation technologies and software

📊Results & Benefits

- ✓Enhanced focus on quality, innovation, and corporate culture post-Toyota acquisition

- ✓Ability to design data-driven systems aimed at delivering maximum Return on Investment (ROI)

- ✓Develops solutions that provide tremendous productivity gains, long-term quality, and reliability

📝Project Overview

Project Overview

Note: This input is a corporate profile and capabilities overview for Bastian Solutions, not a specific warehouse automation project case study. The following structure is adapted to summarize the company's profile based on the provided description.

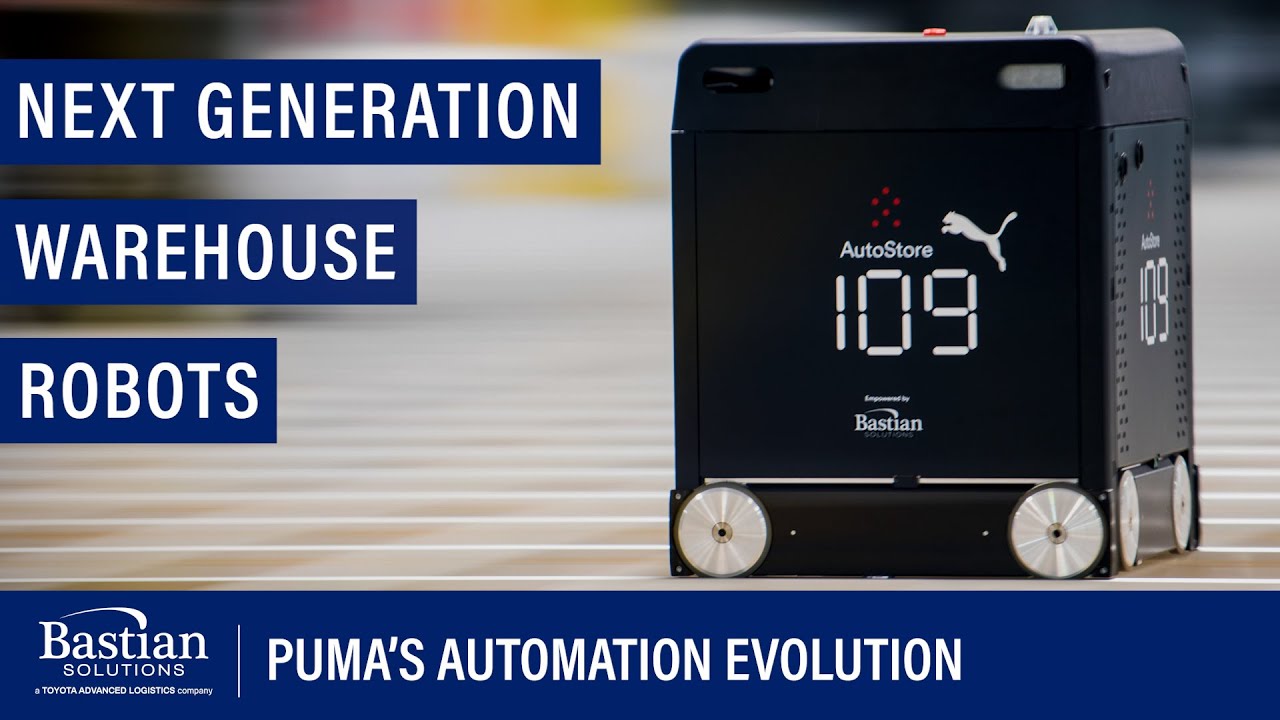

Bastian Solutions is a leading provider of supply chain integration and warehouse automation solutions. Founded in 1952, the company built its reputation on hard work, quality products, an innovative mindset, and a steadfast commitment to its clients. A significant milestone in its history was its 2017 acquisition by Toyota Industries Corporation, which recognized the shared values between the two organizations.

Now operating as a Toyota Advanced Logistics company and a member of the global Toyota family, Bastian Solutions leverages this partnership to reinforce its core mission. The company is focused on creating and innovating world-class distribution and production solutions that make a tangible impact for clients. At the heart of its methodology is the Toyota Production System concept of Jidoka, which translates to "intelligent automation that creates value." This principle guides the design of data-driven systems aimed at delivering maximum return on investment (ROI) by addressing modern consumer demands for speed, accuracy, and flexibility.

Momentum WES: Next-Generation Warehouse Execution and Control

Vendor: Honeywell Intelligrated

Key Features

Bastian's defining characteristic is its dual identity as an established American integrator and a Toyota Advanced Logistics company. This unique position allows it to combine entrepreneurial agility with the world-renowned quality, process discipline, and long-term philosophy of the Toyota Production System, particularly the Jidoka principle.

The company's approach is fundamentally human-centric. It emphasizes that its client-focused solutions are developed by its people—consultants, engineers, technicians, and specialists—who operate within a culture valuing integrity, innovation, diversity, and continuous improvement. Their service model is collaborative, considering each solution on its own merits to ensure it delivers measurable productivity gains and lasting reliability.

Results & Benefits

For its clients, partnering with Bastian Solutions provides access to a blend of deep industry expertise and Toyota-level operational excellence. The post-acquisition focus has intensified efforts on quality, innovation, and culture, which translates into more robust and valuable solutions for end users.

The company's goal is to design systems that are not just technologically advanced but are also financially sound, aiming for maximum ROI through intelligent, data-driven automation. Clients can expect solutions engineered to provide significant productivity improvements while ensuring long-term operational quality and system reliability.

System Integrator

This content is a self-description by Bastian Solutions itself. The company positions itself as the system integrator and "trusted supply chain integration partner" for its clients. It highlights its comprehensive in-house capabilities—from consulting and design to engineering, manufacturing, assembly, and implementation—all backed by the quality standards and innovative spirit of the Toyota family.

🔧Related Technologies (6)

Momentum WES: Next-Generation Warehouse Execution and Control

byHoneywell Intelligrated

Dark Warehouse: Fully Automated Warehouse Operations

byAddverb

MIX: All-round Goods-to-Person Picking Solution

byMushiny

Industrial Robot Arms in Logistics: Order Fulfillment Applications

byYaskawa

Autopicker: AI-Powered Mobile Picking Robot

byBrightpick

Mecalux Shuttle System: Automated AS/RS for Boxes and Small Parts

byMecalux

📚Related Knowledge Articles (6)

Voice Picking Systems

Voice picking systems revolutionize warehouse operations by enabling hands-free, eyes-free order fulfillment through speech recognition technology. Workers receive spoken instructions through wireless headsets and confirm actions verbally, dramatically improving productivity, accuracy, and safety while reducing training time.

Goods-to-Person Systems

Goods-to-Person (G2P) systems revolutionize warehouse operations by bringing inventory directly to stationary picking stations, eliminating worker travel time and maximizing productivity. These automated systems combine storage, retrieval, and presentation technologies to create highly efficient picking environments.

Robotic Piece Picking

Advanced robotic systems that use AI and computer vision to automatically select and pick individual items from diverse inventory, revolutionizing warehouse fulfillment operations with human-like dexterity and intelligence.

Pick-to-Light Systems

Pick-to-light systems use illuminated displays at storage locations to guide warehouse workers to the correct items and quantities, dramatically improving picking speed and accuracy.

Carousel Systems

Carousel systems use rotating shelves or bins that automatically deliver items to stationary operators, improving picking productivity and space utilization through goods-to-person automation.

Shuttle Systems

Shuttle systems use autonomous vehicles traveling on rails within racking structures to store and retrieve totes or cartons, providing flexible high-density automated storage with scalable throughput.