Dark Warehouse: Fully Automated Warehouse Operations

⚡Quick Facts

Technology Performance Metrics

⭐Key Features

✨Benefits

🎯Applications

📝Detailed Information

Technology Overview

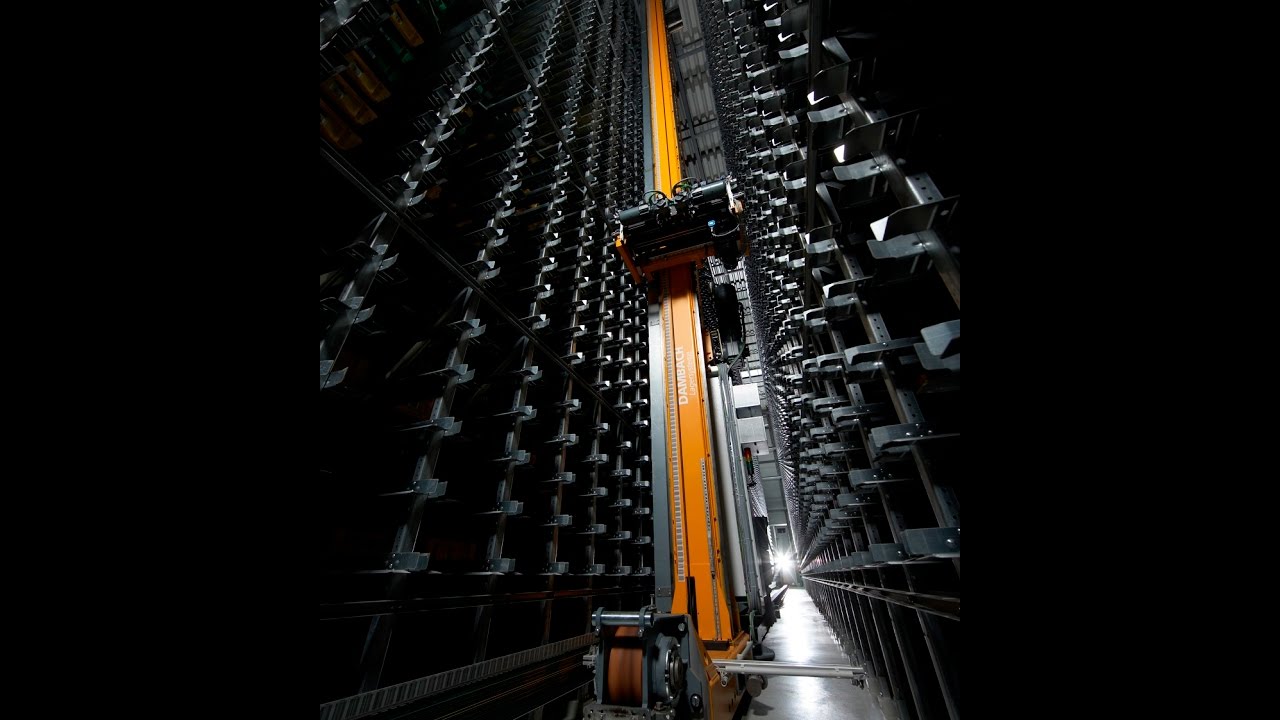

The Dark Warehouse, also known as a lights-out warehouse, represents the pinnacle of warehouse automation. It is a concept and operational model where a distribution center is designed to function with minimal or no human intervention on the floor, enabled by a comprehensive integration of advanced robotics, automated storage and retrieval systems (AS/RS), autonomous mobile robots (AMRs), and sophisticated control software. The goal is to achieve 24/7 operational capability, where machines handle tasks from receiving and putaway to picking, sorting, and internal transport with high speed and accuracy. While some complex peripheral processes like initial goods receipt or final packaging may still involve humans, the core material flow within the "dark" installation is fully automated. This approach is driven by the pursuit of maximum efficiency, safety, and cost reduction, particularly for businesses managing vast inventories and demanding fulfillment schedules.

How It Works

Core Principles

The core principle is the replacement of human labor with automated systems for all repetitive, predictable material handling tasks. A central software brain (WES/WMS) receives orders, plans all activities, and dispatches instructions to a fleet of robotic assets. These assets—including AS/RS for dense storage, AMRs for horizontal transport, and robotic sorters for order consolidation—execute the physical work independently, communicating their status back to the control system in a continuous loop.

Key Features & Capabilities

24/7 Unattended Operation: The defining feature is the ability to run continuously without being constrained by human shifts, dramatically increasing potential throughput and responsiveness.

Integrated Robotic Ecosystem: A Dark Warehouse is not a single technology but a seamlessly integrated ecosystem of complementary automation—AS/RS for storage density, AMRs for flexibility, and sortation robots for speed—all working in concert.

Software-Driven Orchestration: The entire operation is governed by advanced software that performs real-time optimization, inventory management, and exception handling, making the complex automation work cohesively.

High-Density Storage Optimization: The design prioritizes maximizing cube utilization through dense racking and vertical AS/RS, enabling more inventory to be held in a smaller footprint.

Advantages & Benefits

The primary benefit is a dramatic increase in operational efficiency; automated systems work faster, with more consistency, and without fatigue, leading to higher throughput and shorter order cycle times. Labor cost reduction is significant as the need for personnel for picking, putaway, and internal transport is eliminated or greatly minimized. Safety is substantially improved by removing humans from potentially hazardous environments involving heavy loads and moving machinery. For businesses with large SKU counts, inventory management becomes highly optimized through software-controlled storage and retrieval. Furthermore, space utilization is maximized through vertical storage automation.

Implementation Considerations

Establishing a Dark Warehouse requires a very high initial capital investment in hardware, software, and systems integration. The design and implementation are highly complex, requiring meticulous planning of workflows, equipment interoperability, and software logic. While core operations are automated, some processes like receiving, complex packaging, or system maintenance will still require human expertise. The operation becomes highly dependent on the reliability of both hardware and software; any significant downtime can halt the entire facility, necessitating robust maintenance and support plans.

Use Cases & Applications

Ideal For

This model is ideal for very high-volume e-commerce fulfillment centers, distributors for large retailers, and any operation where order volume and SKU count justify the massive investment, and where speed, accuracy, and 24/7 operation provide a critical competitive edge.

Performance Metrics

While specific numbers are not provided, the system is designed for maximum throughput and 24/7 uptime. Key performance gains are greatly reduced order cycle times, near-elimination of picking/putaway errors, maximized storage density per square foot, and a significant reduction in cost per picked item due to labor savings. The improvement in safety is a critical qualitative metric.

Conclusion

The Dark Warehouse represents the ultimate vision of warehouse automation—a self-operating, highly efficient logistics engine. For companies at the forefront of scale and speed, it offers a transformative path to overcome labor challenges, space constraints, and accuracy limitations. While the journey to a fully lights-out facility is capital-intensive and complex, the potential rewards in efficiency, cost savings, and competitive advantage are substantial. Addverb's integrated approach, combining hardware expertise with software intelligence, exemplifies how this future is being built today. It is a strategic investment for businesses looking to define the next decade of logistics performance.

📦Related Projects

Landmark Group Kuwait Fulfillment Center

Landmark Group partnered with Addverb to modernize its Kuwait fulfillment center with robotic sorters and carton shuttles, achieving up to 1,000 sorts per hour for enhanced e-commerce operations.

Addverb 3PL Omnichannel Fulfillment Center

Addverb transformed a 330,000 sq. ft. 3PL facility with integrated fixed and flexible automation, enabling seamless B2B and B2C operations and a dispatch of 100,000 pieces daily.

Dongfeng Motor R&D Center Smart Logistics Warehouse

A compact 470㎡ intelligent warehouse with 15-level high-density storage supporting 10,000+ SKUs for automotive R&D supply chain optimization.