Push-Back Racking

Push-back racking stores pallets on nested carts that push back as new pallets are loaded, providing LIFO storage 2-6 pallets deep with higher density than selective racking and faster operation than drive-in systems.

Push-Back Racking Overview

System Features

- •Nested CartsPallets on wheeled carts

- •LIFO OperationLast-in-first-out

- •Gravity-FedAuto advancement

- •Single AisleLoad and pick same side

Cart Systems

- •Nested DesignCarts nest together

- •TelescopingCompact configuration

- •2,000-4,000 lbsLoad capacity

- •Sealed BearingsSmooth rolling

Applications

- •Food and BeverageNon-perishable bulk

- •Retail DistributionSeasonal items

- •ManufacturingFinished goods

- •WholesaleBulk storage

Key Benefits

- •60-70% Densityvs. 40-50% selective

- •Faster Than Drive-InBetter access

- •No Lane EntryReduced damage

- •Self-FeedingAutomatic advance

Configuration

- •Depth: 2-6 Pallets4-5 typical

- •Height: Up to 30ftMultiple levels

- •Slope: 3-5%Optimal gradient

- •Aisle: 10-12ftStandard width

Future Trends

- •Smart CartsIoT sensors

- •Advanced MaterialsLightweight, durable

- •AGV IntegrationAutomated loading

- •Hybrid SystemsMix configurations

How Push-Back Racking Works

The system uses wheeled carts that nest together when empty and separate as pallets are loaded. Each cart rides on inclined rails (typically 3-5% slope) within the racking structure, with gravity providing the force that returns carts to the front position when pallets are removed. The cart design varies by manufacturer but typically includes a pallet support surface, wheels or rollers that ride on the rails, and nesting features that allow carts to stack compactly when not supporting pallets. The carts are designed to support typical pallet loads of 2,000-4,000 pounds while maintaining smooth, controlled movement along the rails.

Loading operations involve forklifts placing pallets on the front cart, which then rolls backward along the inclined rails as the pallet weight overcomes the gravity force. The cart movement exposes the next cart in the sequence, ready to receive the subsequent pallet. This process continues until all cart positions are filled (typically 2-6 pallets deep). The incline angle is carefully calculated to ensure that loaded carts move backward reliably when new pallets are added but don't roll forward uncontrollably when pallets are removed. Speed control is inherent in the system design through the rail angle and cart friction characteristics, eliminating the need for active braking systems required in pallet flow racking.

Retrieval operations are simple and efficient—forklifts remove the front pallet, and the remaining carts automatically roll forward under gravity, presenting the next pallet for picking. The automatic advancement eliminates the need for operators to drive into lanes (as with drive-in racking) or manually reposition carts, improving cycle times and reducing the risk of rack damage. The system continues to present pallets at the front position until all pallets in the lane are depleted, at which point the empty carts nest together at the rear of the lane, ready for the next loading cycle.

Lane configuration typically ranges from 2-6 pallets deep, with depth determined by operational requirements and cost considerations. Shallower systems (2-3 pallets deep) provide better accessibility and faster throughput but deliver less density improvement over selective racking. Deeper systems (4-6 pallets deep) maximize storage density but increase system cost and may reduce throughput slightly. Most operations find optimal performance with 3-4 pallet depths that balance density, cost, and operational efficiency, though specific requirements vary based on SKU characteristics and facility constraints.

Key Benefits

The primary advantage of push-back racking is improved storage density compared to selective racking while maintaining better accessibility and throughput than drive-in systems. The 60-70% space utilization represents a 40-50% improvement over selective racking's 40-50%, enabling facilities to store significantly more inventory in the same footprint. Unlike drive-in racking where forklifts must enter lanes and navigate confined spaces, push-back systems allow all loading and retrieval from the aisle, reducing cycle times and minimizing the risk of rack damage from forklift contact.

Faster operation than drive-in racking results from the single-aisle access and automatic pallet presentation. Operators don't need to drive into lanes, position pallets on rails at depth, or navigate backward out of confined spaces. The reduced cycle times—typically 30-50% faster than drive-in operations—improve throughput and labor productivity, particularly valuable for operations with moderate to high pallet movement volumes. The faster operation also reduces forklift operating costs and enables facilities to handle more volume with the same equipment fleet.

Lower risk of rack damage compared to drive-in systems results from eliminating forklift travel within the rack structure. All forklift operations occur in the aisle, where operators have better visibility and more maneuvering space. The cart system absorbs minor impacts and misalignments that might damage structural components in drive-in systems, reducing maintenance costs and extending system lifespan. Operations typically experience 50-70% fewer damage incidents with push-back compared to drive-in racking, lowering repair costs and improving safety.

Flexibility for medium SKU counts makes push-back suitable for operations with 100-500 SKUs that need better density than selective racking but can't justify drive-in systems due to insufficient pallet quantities per SKU. Each lane can accommodate a different SKU, and the 2-6 pallet depth works well for products with moderate inventory levels. The LIFO rotation is acceptable for many non-perishable products, while the improved accessibility compared to drive-in systems provides more operational flexibility for managing diverse product mixes.

Common Applications

Distribution centers with moderate SKU counts and multiple pallets per SKU use push-back racking to optimize space utilization while maintaining good operational efficiency. Operations managing 100-500 SKUs with 3-10 pallets per SKU find push-back provides an excellent balance of density and accessibility. The system works particularly well for slow to medium-velocity items where the LIFO rotation is acceptable and the improved density justifies the higher cost compared to selective racking. Many facilities use push-back for bulk storage combined with selective racking for active picking.

Manufacturing facilities leverage push-back racking for finished goods staging and component storage where products accumulate before shipment or consumption. The LIFO rotation aligns well with manufacturing patterns where products are produced in batches and consumed or shipped in similar sequences. The space efficiency maximizes storage capacity in constrained manufacturing facilities, while the faster operation compared to drive-in systems supports the responsive material movement required in production environments.

Retail distribution operations use push-back for seasonal products and promotional items that arrive in bulk quantities and are depleted relatively quickly. The high density accommodates the inventory peaks associated with seasonal demand, while the LIFO rotation is acceptable for products with adequate shelf lives. The quick reconfiguration capability allows facilities to reassign lanes to different products as seasonal assortments change, providing the flexibility needed in dynamic retail supply chains.

Cold storage facilities implement push-back racking to improve storage density while maintaining better operational efficiency than drive-in systems. The reduced forklift travel within temperature-controlled areas lowers energy costs by minimizing the time dock doors remain open and reducing the volume of cold air that must be replaced. The faster cycle times compared to drive-in systems improve throughput, particularly important in cold environments where operator productivity typically decreases 20-30% compared to ambient conditions.

Implementation Considerations

Successful push-back implementation requires careful evaluation of product characteristics to ensure compatibility with LIFO rotation and cart-based storage. Products must have adequate shelf lives to accommodate LIFO rotation without creating obsolescence issues—typically 6+ months for non-perishable goods. Pallet condition is important, as damaged pallets may not sit properly on carts or could jam during movement. Operations should implement pallet quality standards to ensure reliable system operation and minimize maintenance requirements.

Lane depth selection should consider pallet quantities per SKU, product velocity, and cost constraints. Operations with 3-6 pallets per SKU typically use 3-4 deep systems, while those with 6-12 pallets per SKU may justify 5-6 deep configurations. Deeper systems cost more due to additional carts and longer rails but deliver better density. The analysis should compare the incremental cost of additional depth against the space savings achieved to determine optimal configuration for specific operational requirements.

Aisle width requirements are similar to selective racking—typically 10-12 feet for counterbalance forklifts or 8-10 feet for reach trucks. The front-only access eliminates the wider aisles required for drive-in systems, improving overall space utilization. The facility layout should provide adequate aisle space for safe forklift operation while maximizing the number of push-back lanes that can be installed. Traffic flow patterns should be analyzed to ensure that aisle configurations support efficient material movement without creating congestion.

Floor conditions must support the racking loads and provide a level surface for proper cart operation. While push-back systems don't require the specialized floor preparation needed for mobile racking, the floor should be reasonably level (within 1/4 inch in 10 feet) to ensure proper cart movement and prevent binding. Floor load capacity requirements are similar to selective racking—typically 4,000-6,000 PSF—making push-back suitable for most warehouse facilities without special reinforcement.

Best Practices

Product assignment strategies should consider velocity and pallet quantities to optimize system utilization. Medium-velocity items with 3-10 pallets per SKU represent ideal candidates for push-back racking, as they benefit from the density improvement while the LIFO rotation doesn't create significant operational issues. Slower-moving products can use deeper configurations (5-6 pallets) to maximize density, while faster-moving items may use shallower systems (2-3 pallets) to improve throughput and reduce the impact of LIFO rotation.

Load quality standards ensure reliable cart operation and minimize maintenance requirements. Pallet overhang should be minimized to prevent pallets from catching on carts or structural components during movement. Load stability must be adequate to withstand the movement and potential impacts as carts roll along rails. Weight distribution should be reasonably uniform to prevent carts from tilting or binding during operation. Clear standards and operator training support consistent load quality that enables reliable system performance.

Regular maintenance includes inspecting cart condition, checking rail alignment, verifying proper slope, and replacing worn components. Monthly inspections should check for damaged carts, debris on rails, and proper pallet positioning. Quarterly maintenance should include lubricating cart wheels, checking structural integrity, and verifying that carts nest and separate properly. Annual professional inspections provide comprehensive assessments and identify potential issues before they cause operational disruptions or safety concerns.

Inventory management must account for LIFO rotation when planning replenishment and managing product dating. The warehouse management system should track which pallets are in which positions within lanes to support cycle counting and inventory accuracy. Minimum/maximum inventory levels should be set considering the lane depth and LIFO rotation to prevent obsolescence while maintaining adequate stock levels. Some operations use date code tracking to ensure that products don't exceed shelf life limits despite LIFO rotation.

Measuring Success

Key performance indicators for push-back racking include space utilization (target 60-70%), pallets stored per square foot, average cycle time per pallet, and damage incidents per month. These metrics help operations evaluate whether the system delivers expected density benefits while maintaining acceptable operational efficiency and reliability. Comparing cost per pallet stored against selective and drive-in alternatives validates the economic benefits for specific operational requirements.

Throughput performance should show improved productivity compared to drive-in systems, with cycle times typically 30-50% faster for loading and retrieval operations. Tracking pallets moved per hour and labor productivity helps quantify the operational benefits. While push-back systems have slightly lower throughput than selective racking due to the LIFO access pattern, the density improvement often justifies the trade-off for appropriate applications.

Return on investment typically materializes over 2-4 years through improved space utilization, reduced facility costs, and better operational efficiency compared to drive-in systems. The space savings of 40-50% compared to selective racking enable facilities to store more inventory in the same footprint or defer facility expansion. The faster operation compared to drive-in systems reduces labor costs and improves throughput, particularly valuable for operations with moderate to high pallet movement volumes.

System reliability should show minimal cart failures, binding issues, or operational disruptions. Tracking maintenance requirements, cart replacement frequency, and system downtime helps assess whether the system is performing as expected. Well-maintained push-back systems typically operate reliably for 15-20 years with minimal maintenance beyond periodic cart replacement and rail inspection.

By implementing push-back racking with careful attention to product characteristics, lane depth optimization, and maintenance practices, facilities can achieve excellent balance of storage density, operational efficiency, and system cost. The proven technology and favorable economics make push-back racking a valuable solution for operations with medium SKU counts, multiple pallets per SKU, and acceptable LIFO rotation.

🔧Related Technologies (6)

Live Storage Systems: Gravity-Flow High-Density Storage

byAR Racking

Pushback Pallet Rack: High-Density Multi-SKU Storage

byOthers

Push-Back Pallet Rack: High-Density LIFO/FIFO Storage

byOther

Push-Back Racking: High-Density LIFO Storage Solution

byAtlantic Rack

Dark Warehouse: Fully Automated Warehouse Operations

byAddverb

MIX: All-round Goods-to-Person Picking Solution

byMushiny

📚Related Storage Topics

About This Topic

📁Related Projects(6)

Bastian Solutions Corporate Profile: Toyota Advanced Logistics

Bastian Solutions

MULTIFLEX Pallet Warehouse: High-Density Frozen Storage

MFI (implied contractor)

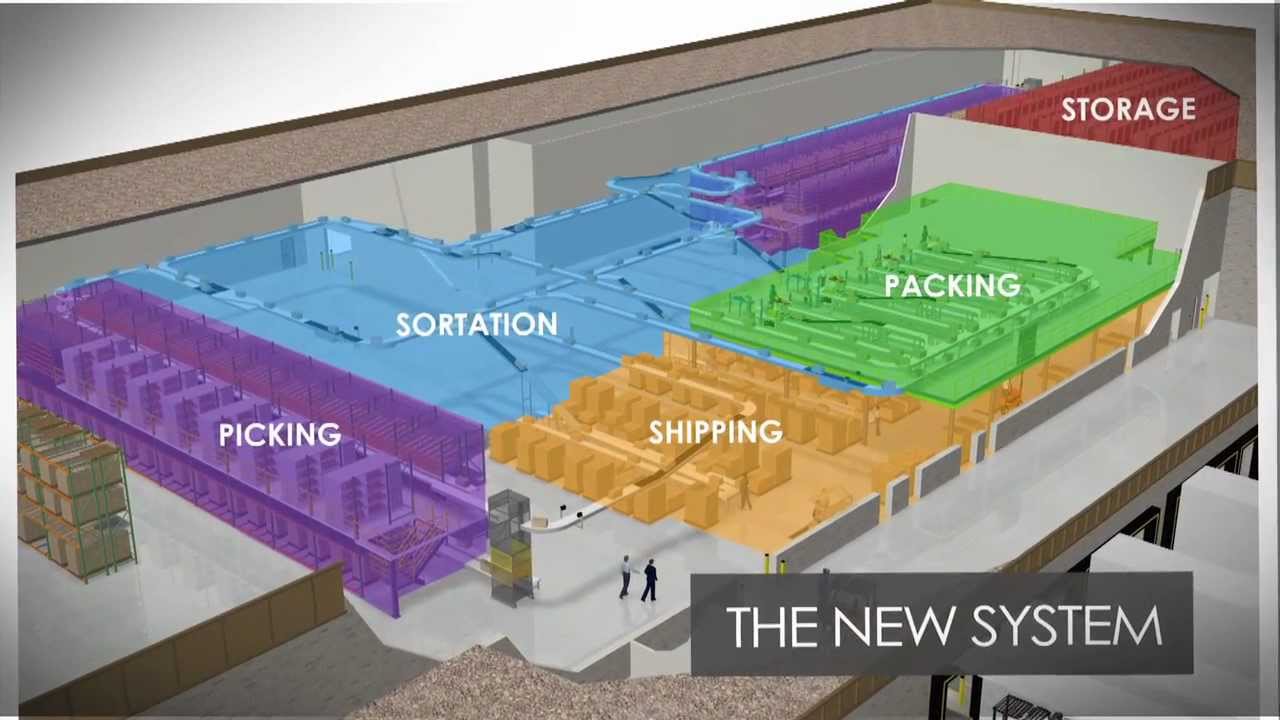

Amway Midwest Regional Service Center, Ada

Bastian Solutions

Roche Diagnostics Indianapolis Distribution Center

Bastian Solutions

Addverb 3PL Omnichannel Fulfillment Center

Addverb

SEW-EURODRIVE Bruchsal Electronics Plant

GEBHARDT Intralogistics Group

🏢Related Suppliers(3)

Exotec

Elegant Solutions to Simplify Logistic Operations

Symbotic

AI-Powered Warehouse Automation Systems

Boston Dynamics

Advanced robotics company developing mobile robots for industrial automation and logistics applications.