Mobile Racking

Mobile racking systems mount pallet racks on motorized bases that move along floor rails, eliminating fixed aisles to achieve 80-90% space utilization while maintaining full pallet selectivity.

Mobile Racking (Movirack) Overview

System Features

- •Movable RacksEntire units on rails

- •Aisle on DemandCreate access anywhere

- •100% SelectivityAccess every pallet

- •High Density80-90% utilization

Drive Types

- •Electric MotorPush-button control

- •Mechanical DriveHand-crank operation

- •Manual PushDirect force

- •Remote ControlAdvanced systems

Applications

- •Cold StorageMaximize refrigerated space

- •ArchivesDocument storage

- •ManufacturingSpare parts

- •Retail DistributionHigh SKU count

Key Benefits

- •Double Capacityvs. selective racking

- •Energy Savings40-60% in cold storage

- •Full AccessEvery pallet reachable

- •Space OptimizationEliminate fixed aisles

Safety Features

- •Presence DetectionSensors in aisles

- •Auto-StopImmediate halt

- •Audible WarningsMovement alerts

- •Locking MechanismsSecure during access

Future Trends

- •IoT MonitoringReal-time tracking

- •AI OptimizationSmart aisle management

- •AGV IntegrationAutonomous vehicles

- •Energy EfficiencyRegenerative systems

How Mobile Racking Works

The system consists of standard pallet racking mounted on motorized carriages that travel along floor rails embedded in or mounted on the warehouse floor. Each rack row moves independently, controlled by push-button panels, remote controls, or automated control systems that respond to operator commands or warehouse management system integration. The drive mechanisms typically use electric motors powered by building electrical systems, though some installations use hydraulic or mechanical drive systems depending on load requirements and facility characteristics.

Safety systems are comprehensive and redundant, incorporating multiple technologies to prevent accidents during rack movement. Photocell barriers at aisle entries detect personnel or equipment in the aisle and prevent rack movement until the aisle is clear. Pressure-sensitive mats on the floor detect weight and stop movement if someone enters the aisle. Emergency stop buttons at multiple locations enable immediate shutdown if needed. Audible and visual warnings alert personnel before and during rack movement, while speed controls limit movement velocity to safe levels (typically 20-40 feet per minute). These safety features ensure that mobile racking operates safely despite the inherent risks of moving multi-ton structures in occupied warehouses.

Floor rail systems must be precisely installed and maintained to ensure smooth, safe operation. The rails are typically steel channels embedded in concrete floors or mounted on the surface, with precise alignment and levelness critical for proper operation. Floor load capacity becomes a major consideration, as the concentrated loads from mobile bases can exceed 10,000-15,000 PSF compared to 4,000-6,000 PSF for conventional racking. Many installations require floor reinforcement or specialized foundation work to support the loads, particularly in facilities not originally designed for mobile racking.

Control systems range from simple manual push-button operation to sophisticated automated systems integrated with warehouse management software. Manual systems require operators to press buttons at each rack row to create aisles where needed, suitable for smaller installations or operations with lower throughput requirements. Semi-automated systems use remote controls or centralized control panels that allow operators to open specific aisles from a distance, improving efficiency and safety. Fully automated systems integrate with WMS to automatically open aisles based on pick lists or putaway tasks, maximizing efficiency in high-throughput operations while minimizing operator intervention.

Key Benefits

The primary advantage of mobile racking is maximum storage density while maintaining full pallet selectivity. Unlike drive-in or push-back systems that sacrifice accessibility for density, mobile racking provides direct access to every pallet position by creating aisles on demand. This combination of 80-90% space utilization with 100% selectivity is unique among high-density storage solutions, making mobile racking valuable for operations that cannot accept the accessibility limitations of other dense storage methods. The ability to access any pallet at any time supports FIFO or LIFO rotation, diverse SKU mixes, and strict inventory control requirements.

Space savings of 40-60% compared to conventional selective racking translate directly to reduced facility costs. Operations can store the same inventory in significantly less floor space, enabling them to defer facility expansion, reduce real estate costs, or repurpose freed space for other value-adding activities. In expensive real estate markets or specialized facilities like cold storage, the space savings often justify the higher capital investment required for mobile systems. The return on investment typically ranges from 3-7 years depending on real estate costs, storage requirements, and operational characteristics.

Environmental control efficiency makes mobile racking particularly valuable for cold storage, clean rooms, and other controlled environments. The reduced building volume that must be maintained at specific temperatures or cleanliness levels lowers both construction costs and ongoing operational expenses. Cold storage facilities can achieve 30-50% energy savings compared to conventional racking by minimizing the volume requiring temperature control. Clean room applications benefit from reduced air handling requirements and lower contamination risks in the more compact footprint.

Security and access control improve in mobile racking installations, as the system can be configured to restrict access to specific rack rows or storage zones. Electronic access controls integrated with the movement system ensure that only authorized personnel can open specific aisles, valuable for operations storing high-value products, controlled substances, or sensitive materials. The ability to close all aisles when the facility is unoccupied also provides physical security by making stored products inaccessible without operating the system.

Common Applications

Cold storage and frozen food facilities represent a major application for mobile racking, where the combination of maximum density and full selectivity optimizes both space utilization and operational efficiency. The reduced building volume requiring temperature control lowers energy costs significantly, while the full pallet accessibility supports efficient order fulfillment and strict FIFO rotation for date-sensitive products. Many cold storage operations achieve payback periods of 3-5 years through the combination of reduced building costs, lower energy expenses, and improved operational efficiency.

Pharmaceutical and healthcare facilities use mobile racking for storing medications, medical supplies, and controlled substances where both high density and strict inventory control are required. The access control capabilities support regulatory compliance by restricting access to controlled substances, while the full selectivity enables precise inventory tracking and lot traceability. Climate-controlled storage for temperature-sensitive medications benefits from the reduced volume requiring environmental control, lowering both capital and operating costs.

Archives and document storage operations leverage mobile racking for high-density storage of records, files, and documents where space efficiency is critical but complete accessibility must be maintained. Law firms, government agencies, healthcare providers, and corporations use mobile systems to maximize storage capacity in expensive urban real estate while ensuring that any document can be retrieved on demand. The security features support compliance with privacy regulations and protect sensitive information from unauthorized access.

Specialty manufacturing facilities with limited floor space use mobile racking for storing components, raw materials, and finished goods where both density and accessibility are important. Operations producing diverse product mixes with varying component requirements benefit from the full selectivity that supports efficient material handling, while the high density maximizes storage capacity in constrained facilities. Clean room manufacturing particularly benefits from the reduced footprint that minimizes the area requiring expensive environmental controls.

Implementation Considerations

Successful mobile racking implementation requires thorough floor assessment to verify capacity for the concentrated loads. The floor must support 10,000-15,000 PSF or more at rail locations, significantly higher than the 4,000-6,000 PSF typical for conventional racking. Many facilities require floor reinforcement, foundation work, or specialized floor construction to support mobile systems. A structural engineer should evaluate floor capacity and recommend any necessary remediation before proceeding with installation, as inadequate floor capacity can lead to cracking, settlement, or structural failure.

Rail installation must be precisely executed to ensure smooth, safe operation. The rails must be perfectly level and aligned to prevent binding, uneven wear, or safety issues during movement. Floor preparation including grinding, leveling, and sealing may be necessary before rail installation. The installation typically requires facility downtime of 2-4 weeks depending on system size and complexity, requiring careful planning to minimize operational disruption. Some installations use surface-mounted rails that avoid cutting into the floor, reducing installation time and preserving floor integrity but creating trip hazards that must be managed.

Electrical infrastructure must provide adequate power for the drive motors, control systems, and safety features. Each mobile base requires electrical connections, typically through conductor rails in the floor or trailing cables that move with the racks. The electrical design must account for the simultaneous movement of multiple rack rows, peak power demands, and backup power requirements for safety systems. Integration with building electrical systems requires coordination with electrical contractors and may necessitate service upgrades in older facilities.

Throughput considerations must be evaluated, as mobile racking typically has lower throughput than conventional selective racking due to the time required to open aisles. Each aisle opening takes 30-60 seconds depending on system size and configuration, which can create bottlenecks in high-throughput operations. Facilities should analyze their pallet movement volumes, peak demand periods, and acceptable cycle times to ensure mobile racking can support operational requirements. Some operations use hybrid approaches with conventional selective racking for high-velocity items and mobile racking for slower-moving inventory.

Best Practices

Zone configuration should organize inventory by velocity and access patterns to optimize operational efficiency. High-velocity items should be stored in zones with dedicated aisles or at the ends of mobile sections where aisle opening time is minimized. Slower-moving products can occupy interior positions where longer access times have less operational impact. Some installations use multiple mobile sections with different configurations optimized for specific inventory characteristics, creating a tiered storage strategy that balances density and accessibility.

Preventive maintenance programs are essential for ensuring reliable operation and long system lifespan. Monthly inspections should check rail alignment, drive mechanism operation, safety system function, and structural integrity. Quarterly maintenance should include lubrication of moving parts, electrical system checks, and safety system testing. Annual professional inspections by qualified technicians provide comprehensive assessments and identify potential issues before they cause failures. Well-maintained mobile racking systems can operate reliably for 20-30 years, while neglected systems may experience frequent breakdowns and safety issues.

Operator training should cover system operation, safety procedures, and emergency protocols. Operators must understand how to open and close aisles safely, recognize and respond to safety system activations, and follow proper procedures for entering and exiting aisles. Emergency procedures including manual operation during power failures and evacuation protocols should be clearly documented and regularly practiced. The training should emphasize that mobile racking requires different operational practices than conventional racking, with particular attention to safety considerations.

Integration with warehouse management systems maximizes operational efficiency by automating aisle opening based on pick lists or putaway tasks. The WMS can pre-open aisles before operators arrive, minimizing wait times and improving throughput. Task sequencing can be optimized to minimize aisle movements by grouping picks or putaways in the same aisle. Real-time status monitoring provides visibility into system operation and alerts management to issues requiring attention.

Measuring Success

Key performance indicators for mobile racking include space utilization (target 80-90%), pallets stored per square foot, average aisle opening time, and system uptime (target 98%+). These metrics help operations evaluate whether the system delivers expected density benefits while maintaining acceptable operational efficiency and reliability. Comparing cost per pallet stored including building, installation, and operating costs validates the economic benefits against alternative storage methods.

Return on investment typically materializes over 3-7 years through reduced facility costs, lower energy expenses (for controlled environments), and improved space utilization. The payback period varies significantly based on real estate costs, with expensive markets or specialized facilities achieving faster returns. Operations should track avoided facility expansion costs, energy savings, and operational efficiency improvements to quantify the full value delivered by mobile racking investments.

Operational efficiency metrics including pallets moved per hour, average cycle time, and throughput capacity help assess whether the system supports operational requirements without creating bottlenecks. While mobile racking typically has lower throughput than conventional selective racking, well-designed installations can achieve acceptable performance for most applications through proper zone configuration, WMS integration, and operational practices.

By implementing mobile racking with careful attention to floor capacity, installation quality, and operational integration, facilities can achieve maximum storage density while maintaining full pallet selectivity. The proven technology and significant space savings make mobile racking a valuable solution for operations with expensive real estate, controlled environments, or specialized storage requirements where both density and accessibility are critical.

🔧Related Technologies (6)

MIX: All-round Goods-to-Person Picking Solution

byMushiny

Mushiny MIX: T-Series Latent Lifting Robot & iRES Goods-to-Person System

byMushiny

Movirack Mobile Pallet Racking: Maximizing Warehouse Space

byMecalux

XP-R Mobile Racking System: High-Density Pallet Storage

byWDX

Pallet Racking Systems: Configurable Warehouse Storage Solutions

byDexion - Gonvarri Material Handling

MOVO Mobile Pallet Racking: Dynamic High-Density Storage

by Dexion - Gonvarri Material Handling

📚Related Storage Topics

About This Topic

📁Related Projects(6)

MPE Plastics Turin Automotive Warehouse

SSI Schaefer

MULTIFLEX Pallet Warehouse: High-Density Frozen Storage

MFI (implied contractor)

Bastian Solutions Corporate Profile: Toyota Advanced Logistics

Bastian Solutions

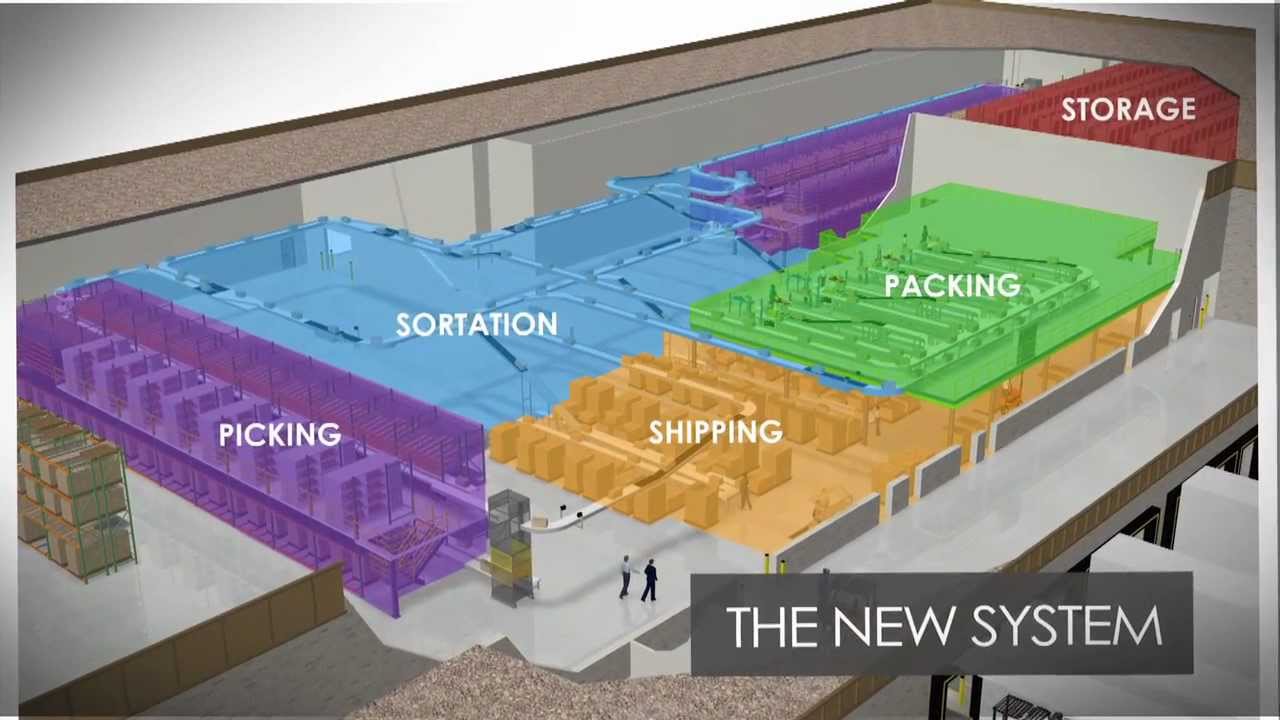

Amway Midwest Regional Service Center, Ada

Bastian Solutions

Roche Diagnostics Indianapolis Distribution Center

Bastian Solutions

Addverb 3PL Omnichannel Fulfillment Center

Addverb

🏢Related Suppliers(3)

Exotec

Elegant Solutions to Simplify Logistic Operations

Symbotic

AI-Powered Warehouse Automation Systems

Boston Dynamics

Advanced robotics company developing mobile robots for industrial automation and logistics applications.