Our Curated Projects

15 projects

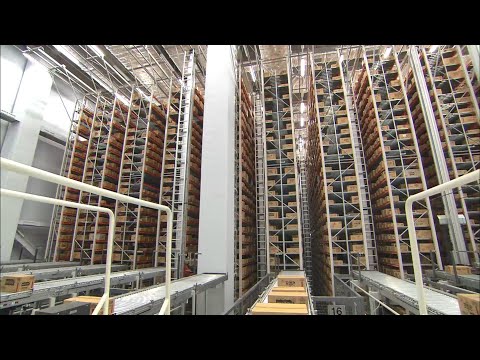

Daifuku Intralogistics India Hyderabad Manufacturing Facility

Daifuku Intralogistics India launched its first-ever 30-meter-tall stacker crane manufactured entirely in India, representing a major milestone for the Make in India initiative and local advanced intralogistics production.

UK Mail - Purpose-Built Automated Parcel Sortation Hub

UK Mail partnered with BEUMER Group to build a future-ready automated parcel sortation hub, featuring two LS-4000CB cross-belt sorters and scalable design to support ongoing e-commerce-driven growth.

Peterbilt - ASRS Aisle 4 Retrofit Project

Peterbilt retrofitted ASRS Aisle 4 to increase storage capacity for large integral cab sleeper units, completed 6 weeks early with no production disruptions by Daifuku.

Lotte Korea Confectionery Centralized Distribution Center

A leading Korean confectionery producer consolidated its logistics by building a massive automated DC next to its factory, featuring ambient & freezer AS/RS and a Mini Load system to handle 25,000 cases daily.

Deli Group Ninghai Intelligent Logistics Center

China's leading office supplies manufacturer built a 110,000 sq m intelligent logistics center with a multi-system AS/RS complex, AMRs, and picking robots to process 200,000 cases daily and store 130,000 pallets.

Lao Gan Ma Guiyang Guizhou Production Warehouse

The iconic Chinese chili sauce brand automated its production logistics with a large-scale Unit Load AS/RS, palletizing robots, and STVs to connect 7 lines across 6 factories, achieving high inbound/outbound throughput.

Sengkang General Hospital Singapore Central Sterile Supply Unit

A Singapore hospital transformed its surgical instrument logistics with a mini load AS/RS, vertical carousels, and robotic picking, integrated with barcode tracking and WMS/WCS to optimize the sterile supply flow.

Vinamilk Saigon Dairy Factory Cold Storage Warehouse

Vietnam's leading dairy producer implemented a cold-environment Automated Storage and Retrieval System (AS/RS) that quadrupled storage capacity while enhancing efficiency and quality control in its logistics operations.

Home Bargains Amesbury Distribution Center

Home Bargains implemented Lowpad's AMR solution with 91 robots to automate marshalling and process 200,000 roll cages weekly, addressing recruitment challenges in remote location.

NEXT Doncaster Furniture Distribution Center

NEXT implemented Körber's automated pallet handling solution with RGVs and ASRS across two warehouses for fast furniture and goods movement with 77,000 pallet locations.