Daifuku Intralogistics India Hyderabad Manufacturing Facility

⭐Key Features

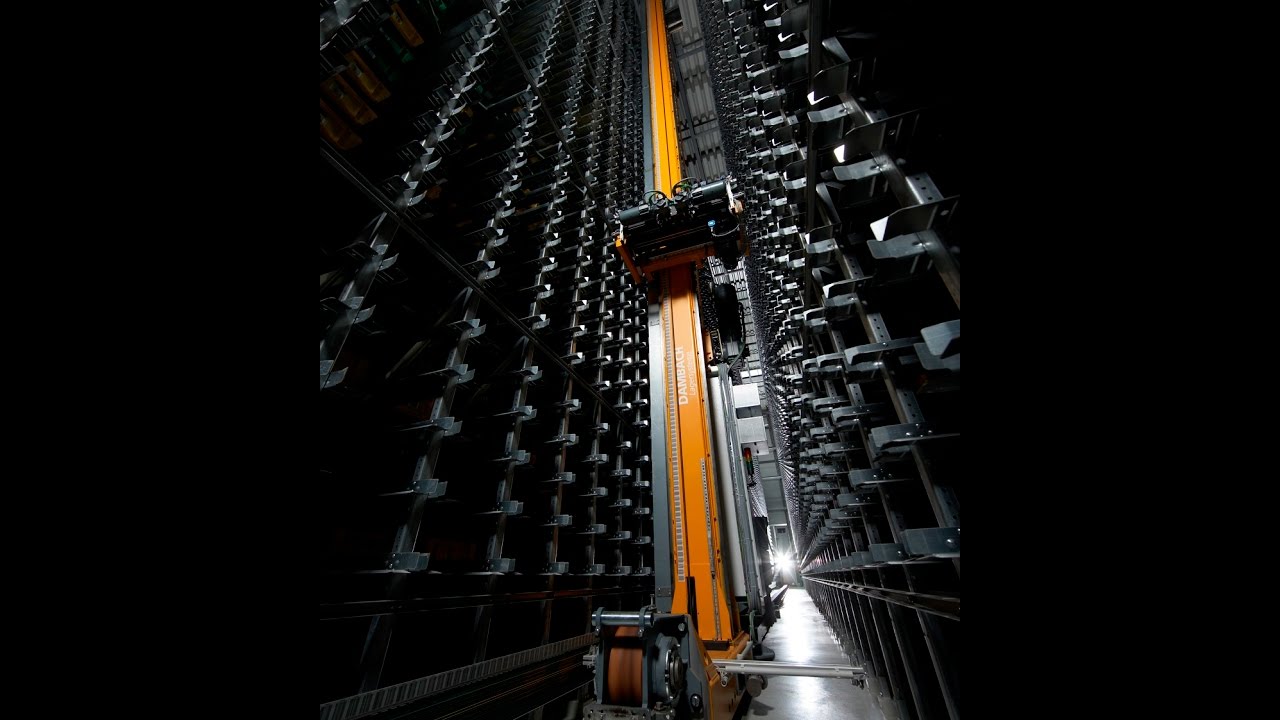

- •First stacker crane entirely manufactured in India by Daifuku

- •30 meters tall, built to global Japanese quality standards

- •Manufactured at Daifuku's advanced facility in Hyderabad

- •Represents a major milestone for the Make in India initiative

- •Engineered for error-free manufacturing and precision performance

📊Results & Benefits

- ✓Successfully launched the first domestically manufactured stacker crane

- ✓Backed by a ₹227 crore investment in the Hyderabad facility

- ✓Strengthens India's position in advanced intralogistics manufacturing

- ✓Creates skilled employment opportunities

- ✓Localizes world-class automation capabilities for key Indian industries

🎯Challenges & Solutions

Achieving the vision of manufacturing high-quality, complex intralogistics equipment like stacker cranes within India.

Established an advanced manufacturing facility in Hyderabad with a ₹227 crore investment, combining global (Japanese) expertise with local talent and engineering to produce the crane 'right the first time'.

📝Project Overview

Project Overview

This project marks a significant corporate and manufacturing milestone for Daifuku Intralogistics India rather than a specific customer warehouse. The company successfully designed, engineered, and built its first-ever stacker crane entirely within India. This achievement is positioned as a landmark moment for the "Make in India" initiative, showcasing the country's growing capabilities in advanced intralogistics manufacturing.

The 30-meter-tall stacker crane was manufactured at Daifuku's newly inaugurated, state-of-the-art facility in Hyderabad. The project underscores a long-term commitment to the Indian market, following Daifuku's initial entry in 2005 and the acquisition of Vega Conveyors in 2019, culminating in this local production capability.

The goal was to produce a critical component of Automated Storage and Retrieval Systems (AS/RS) domestically, adhering to global Japanese quality standards, to serve various Indian industries such as automotive, FMCG, food & beverage, pharmaceuticals, and e-commerce, while creating skilled jobs and localizing expertise.

Technical Solution

Made-in-India Stacker Crane

The core achievement is the stacker crane itself, a 30-meter-tall automated machine that runs on rails within an AS/RS to store and retrieve unit loads (pallets). This specific crane is the first of its kind to be fully manufactured by Daifuku within India. It is engineered to meet precise design and customer specifications, focusing on error-free manufacturing, quality, and innovation.

Piolax Canton Georgia Automotive Parts Distribution Center

Vendor: Daifuku

Key Features

The primary feature is the crane's status as the first stacker crane completely manufactured in India by Daifuku, symbolizing a leap in local technical prowess for the warehouse automation sector.

Despite being manufactured locally, the crane is built to uncompromising global Japanese quality standards, ensuring it delivers the precision engineering and performance excellence associated with Daifuku's international products.

The successful production is underpinned by the new, strategically invested Hyderabad plant, which provides the advanced manufacturing base necessary for such complex equipment.

Results & Benefits

The most direct result is the successful launch and commissioning of the first Indian-manufactured Daifuku stacker crane, achieved "right the first time," demonstrating proven design and engineering capabilities.

The project is backed by a significant ₹227 crore investment in the Hyderabad manufacturing hub, which strengthens India's overall position in the high-value sector of advanced intralogistics manufacturing.

The initiative contributes to skilled job creation within India and localizes world-class automation manufacturing capabilities, reducing dependency on imports and supporting the growth of key Indian industries that utilize AS/RS technology.

Challenges & Solutions

The overarching challenge was realizing the vision of "Make in India" for highly engineered, precision intralogistics equipment like stacker cranes, which require stringent quality control. Daifuku overcame this by making a substantial capital investment (₹227 crore) to establish a modern manufacturing facility in Hyderabad. This plant combined Daifuku's global expertise and Japanese quality standards with Indian engineering talent and workforce to successfully produce the complex machine domestically.

System Integrator

This project is about Daifuku Intralogistics India manufacturing a key component of its own systems. Daifuku is both the manufacturer and the implicit system integrator for the future AS/RS projects that will utilize these locally produced stacker cranes. The company has been present in India since 2005 and strengthened its local design and manufacturing capabilities through the acquisition of Vega Conveyors in 2019, leading up to this manufacturing milestone.

🔧Related Technologies (6)

Piolax Canton Georgia Automotive Parts Distribution Center

byDaifuku

Meyer Corporation USA Cookware Distribution Center

byDaifuku

Intralogistics Innovation Center: Integrated Solutions Showcase

byDaifuku

Swisslog Vectura Pallet Stacker Crane: Energy-Efficient High-Bay AS/RS

bySwisslog

Sorting Transfer Vehicle (STV): High-Speed Pallet Transport

byDaifuku

Mid-Load Automated Storage & Retrieval System (AS/RS)

by Conveyco

📚Related Knowledge Articles (3)

Manufacturing & Industrial Warehousing

Manufacturing warehousing supports production operations with just-in-time material delivery, requiring tight integration with production systems and flexible automation that adapts to changing manufacturing schedules.

Automated Packaging Lines

Comprehensive automated packaging lines that integrate multiple packaging processes into synchronized, high-speed production systems, handling complete packaging workflows from product feeding to final case packing with exceptional throughput and consistency.

Production Logistics Strategy

Production logistics orchestrates the seamless flow of materials, components, and finished goods within manufacturing operations. From just-in-time delivery to line-side replenishment, master the strategies that keep production lines running efficiently while minimizing inventory and maximizing throughput.