Peak Pharmacy Bolsover Distribution Center

⭐Key Features

- •Merged three warehouses into one centralized facility

- •67% of picking volume handled by automated CPS system

- •Integrated four separate software systems

- •Automated pack-to-patient processing

- •Overnight prescription supply to 134 pharmacies

- •MHRA guidelines compliance

📊Results & Benefits

- ✓1.5% of England's prescription items dispensed

- ✓67% of picking volume automated through CPS

- ✓Next-day delivery capability to all pharmacies

- ✓Reduced pressure on pharmacy staff across network

- ✓Better patient journey and safety

🎯Challenges & Solutions

Integrating four separate software systems

Extensive work with software engineering team to create seamless integrations

Transition from paper-based system to full automation

Comprehensive training and change management for staff adaptation

Merging three warehouses into one operational facility

Careful milestone planning and successful on-time implementation

📝Project Overview

Project Overview

Peak Pharmacy, a family-run pharmacy chain established in 1981 and headquartered in Bolsover near Chesterfield, has grown to become one of the UK's largest independent pharmacies. The company operates 134 community pharmacies across England, employing approximately 1,500 people and dispensing about 1.5% of all prescription items across the country.

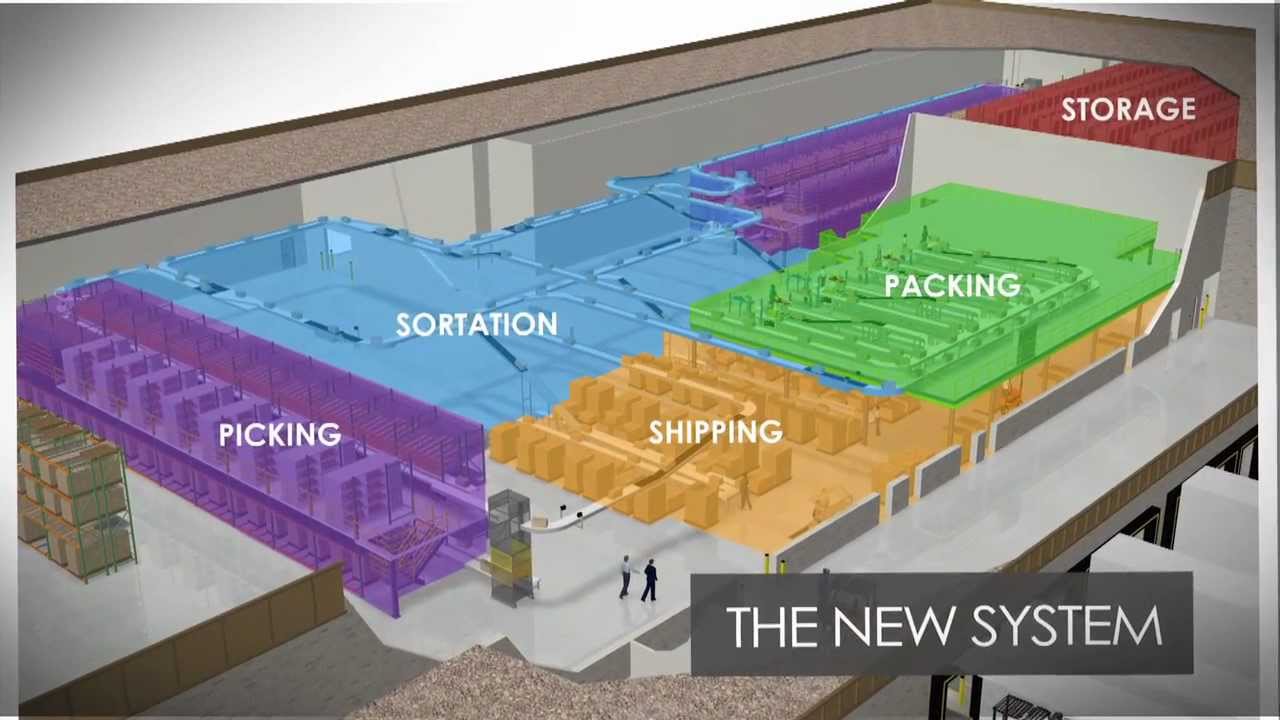

The automation project was conceived five years ago to address the growing demands of pharmaceutical distribution while improving patient care. The primary goal was to merge three separate warehouses into one centralized, automated facility that could reliably supply prescription drugs and other products to all pharmacies overnight while complying with MHRA guidelines.

The transformation enables Peak Pharmacy to free up staff capacity across their branch network, reduce pressure on pharmacy teams, and ultimately provide a better patient journey through more efficient operations and enhanced services.

Technical Solution

Automated Picking System (CPS)

The core automation features KNAPP's CPS (Computerized Picking System) that handles 67% of the total picking volume. This automated system processes the bulk of prescription items, working in coordination with manual picking zones to ensure comprehensive coverage of all pharmaceutical products.

MIX: All-round Goods-to-Person Picking Solution

Vendor: Mushiny

Key Features

The centralized facility successfully merged three separate warehouses into one efficient operation, achieving significant operational synergies and cost savings while maintaining service levels to all 134 pharmacies.

The CPS automated picking system handles 67% of the total volume, dramatically reducing manual labor requirements while improving accuracy and throughput for prescription dispensing operations.

The integrated software platform seamlessly connects four separate systems, providing comprehensive traceability of orders and stock throughout the warehouse while ensuring MHRA compliance.

Results & Benefits

The automated system enables Peak Pharmacy to process 1.5% of England's prescription items efficiently, supporting their position as one of the UK's largest independent pharmacies with reliable overnight delivery to all locations.

Pharmacy staff across the network experience reduced pressure and workload, allowing them to dedicate more time to patient care and additional services rather than manual dispensing tasks.

The pack-to-patient automation and next-day delivery capability create a better patient journey with improved safety, accuracy, and service levels throughout the prescription fulfillment process.

Challenges & Solutions

Integrating four separate software systems presented significant technical challenges. Through extensive collaboration with the software engineering team, Peak Pharmacy successfully created seamless integrations that now support the entire automated operation.

The transition from a completely paper-based system to full automation required comprehensive change management. Despite initial challenges, the team quickly adapted and exceeded volume expectations, particularly during the demanding Christmas period.

Merging three warehouses into one centralized facility required careful milestone planning and execution. The project team successfully hit all planned go-live dates, ensuring a smooth transition to the new automated operation.

System Integrator

KNAPP served as the system integrator, providing the automated infrastructure that ensures reliable overnight supply of prescription drugs while complying with all MHRA guidelines. Their CPS technology and software integration expertise enabled Peak Pharmacy to achieve their strategic objectives of operational efficiency and enhanced patient care.

🖼️Project Gallery

🔧Related Technologies (6)

MIX: All-round Goods-to-Person Picking Solution

byMushiny

Autopicker: AI-Powered Mobile Picking Robot

byBrightpick

Piolax Canton Georgia Automotive Parts Distribution Center

byDaifuku

Pick-it-Easy Robot: Industry-Grade Robotic Picking Solution

byKnapp

Momentum WES: Next-Generation Warehouse Execution and Control

byHoneywell Intelligrated

t-Sort Robotic Unit and Parcel Sortation System: Next-Generation E-commerce Order Fulfillment

byOther

📚Related Knowledge Articles (2)

Pallet Racking

Pallet racking systems are structural storage solutions that hold palletized goods in horizontal rows with multiple levels, forming the backbone of warehouse operations by maximizing vertical space while maintaining direct access to inventory.

Small Load Conveyors

Small load conveyors transport individual items, totes, cartons, and packages through warehouses and distribution centers using belt, roller, or slat systems optimized for lightweight products.