Our Curated Projects

11 projects

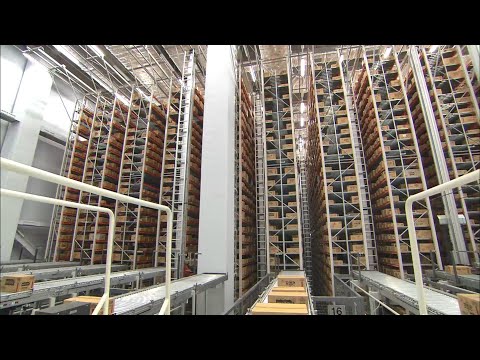

Lotte Korea Confectionery Centralized Distribution Center

A leading Korean confectionery producer consolidated its logistics by building a massive automated DC next to its factory, featuring ambient & freezer AS/RS and a Mini Load system to handle 25,000 cases daily.

Coca-Cola Bottlers Japan Akashi Mega Distribution Center

Part of the Shinsei Project, this mega DC uses a Unit Load AS/RS, Shuttle Rack, palletizing robots, and RORO stations to handle 80 million beverage cases annually, ensuring stable supply for Osaka and Hyogo.

Daifuku Intralogistics India Hyderabad Manufacturing Facility

Daifuku Intralogistics India launched its first-ever 30-meter-tall stacker crane manufactured entirely in India, representing a major milestone for the Make in India initiative and local advanced intralogistics production.

Lao Gan Ma Guiyang Guizhou Production Warehouse

The iconic Chinese chili sauce brand automated its production logistics with a large-scale Unit Load AS/RS, palletizing robots, and STVs to connect 7 lines across 6 factories, achieving high inbound/outbound throughput.

Sengkang General Hospital Singapore Central Sterile Supply Unit

A Singapore hospital transformed its surgical instrument logistics with a mini load AS/RS, vertical carousels, and robotic picking, integrated with barcode tracking and WMS/WCS to optimize the sterile supply flow.

Vinamilk Saigon Dairy Factory Cold Storage Warehouse

Vietnam's leading dairy producer implemented a cold-environment Automated Storage and Retrieval System (AS/RS) that quadrupled storage capacity while enhancing efficiency and quality control in its logistics operations.

Autumn Ocean Conveyor - Oakland Manufacturing Facility Omnichannel Fulfillment Automation

Autumn Ocean Conveyor's Oakland, Illinois manufacturing facility implemented Wind Right's Wind Soft solution with voice-directed technology and barcode scanners to automate inventory processes, improving accuracy and efficiency for omnichannel fulfillment.

Peterbilt - ASRS Aisle 4 Retrofit Project

Peterbilt retrofitted ASRS Aisle 4 to increase storage capacity for large integral cab sleeper units, completed 6 weeks early with no production disruptions by Daifuku.