Our Curated Projects

50 projects

Spar Waalwijk Distribution Center

Spar's mechanized distribution solution handling slow and medium moving items with Swisslog automation, supporting rapid retail expansion of 3 new stores weekly.

Medline Industries Healthcare Distribution Center

First US deployment of Swisslog AutoStore system achieving 1,000 picks per hour per person, five times faster than traditional manual picking for healthcare supply distribution.

PUMA - Geiselwind Multi-Channel Automated Distribution Center

PUMA’s highly-automated distribution center in Geiselwind, Germany, uses TGW’s FlashPick® system (700,000 storage locations) to dispatch 74 million items/year with 10-minute order-to-issue time, serving retail and wholesale channels.

CEWE Stiftung - Oldenburg Production & Distribution Center Automation

psb intralogistics implemented a dynamic pouch sorter and lying goods conveyor system at CEWE Stiftung's Oldenburg facility, handling 2,500 order lines/hour and 4,000 single orders/hour to optimize multi-item order consolidation and shipping efficiency.

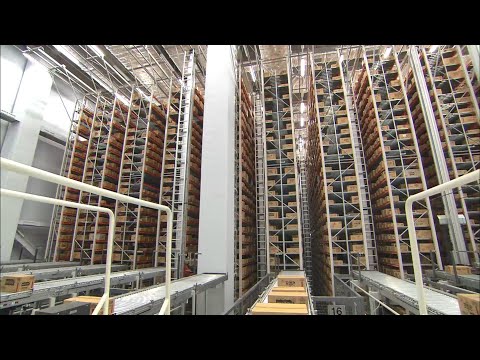

F-Line Japan Major Food Distribution Center

A high-tech food distribution center in Japan automated its entire logistics flow with multiple AS/RS, pallet shuttles, and robotic palletizing to handle 90,000 cases daily from 1.15 million in storage.

Witt-Gruppe Weiden Distribution Center

Witt-Gruppe deployed BEUMER Group's energy-efficient LS-4000 'green' sorters, the world's first of their kind, achieving over 76% annual energy savings and handling 180,000 items daily.

Selfar SA Thessaloniki Pharmaceutical Distribution Center

Selfar SA implemented KNAPP's OSR Shuttle Evo solution for pharmaceutical wholesale distribution, achieving world-record ramp-up in one week despite COVID-19 challenges.

DSV Venlo Distribution Center

DSV commissioned KNAPP with an omnichannel fulfilment solution for their 60,000 sqm distribution centre in Venlo, handling textile and sports sectors for European supply chain centralization.

Jasco - Oklahoma City Omnichannel Distribution Center Automation

Jasco launched a highly automated omnichannel distribution center in Oklahoma City (April 2022) with TGW and Burns & McDonald, handling 20,000+ daily pallet/parcel orders to boost productivity and reduce employee physical strain.

DPD Warszawa - Poland Logistics Center Parcel Sorting Automation

DPD Warszawa implemented BEUMER Group's BG Line Sorter at its Poland logistics center, delivering 1,500-10,000 items/hour throughput with active slat-belt technology for diverse parcel handling.

Notions Marketing Distribution Center with Dematic CMMS - Grand Rapids

A 75-year-old distribution company transformed maintenance operations with Dematic CMMS, reducing reactive repairs by 50% while managing extensive conveyor and sorter networks for big-box retail fulfillment.

Lindab Automated Distribution Center

A 10,600 sqm automated distribution center with high-bay storage handling 250 pallets in/out per hour, featuring 21,500 pallet positions and achieving 50% productivity improvement.

PUMA Indianapolis East Coast Distribution Center

PUMA, NFI/Cal Cartage, and Bastian Solutions deployed North America's largest AutoStore Black Line system, increasing capacity 10x and reducing delivery times from 8 days to 2 days.

South West Healthcare Warrnambool Regional Logistics Distribution Centre

South West Healthcare deployed a Dematic AutoStore system to boost inventory capacity by 500% for its regional medical supply network, storing 6-8 weeks of stock in a reduced footprint.