Weiling GmbH Coesfeld Distribution Center

⭐Key Features

- •AutoStore system with 61 robots and 160 bin presentations per port

- •High-bay warehouse integrated with AutoStore

- •NVision WMS software interface integration

- •Flexible expansion capability in multiple stages

- •Optimized for low turnover rate seasonal articles

- •Excellent space utilization and technology selection

📊Results & Benefits

- ✓Significant improvement in bin presentation capacity

- ✓Expanded capacity to support business growth

- ✓Extended product range capability

- ✓Optimized space utilization for seasonal items

🎯Challenges & Solutions

Managing expanding product range with lower turnover seasonal articles

Implemented AutoStore system that best covers space utilization and turnover rate requirements

Need for future-ready automation solution with expansion capability

Flexible AutoStore system allowing robot expansion in multiple stages

📝Project Overview

Project Overview

Weiling GmbH, founded in 1975 as a small family business in Coesfeld, has grown into one of Germany's largest wholesalers of organic food with approximately 700 employees and an annual turnover of €261 million. The company faced the dual challenge of expanding capacity while extending its product range to meet growing market demands.

The automation project at the Coesfeld site was driven by the need to accommodate an expanding product range, particularly for seasonal articles with lower turnover rates. The company sought a future-ready logistics solution that could flexibly adapt to evolving requirements while optimizing space utilization.

Swisslog served as the system integrator, building on an established relationship with Weiling GmbH to deliver a comprehensive automation solution combining AutoStore technology with high-bay warehouse systems.

Technical Solution

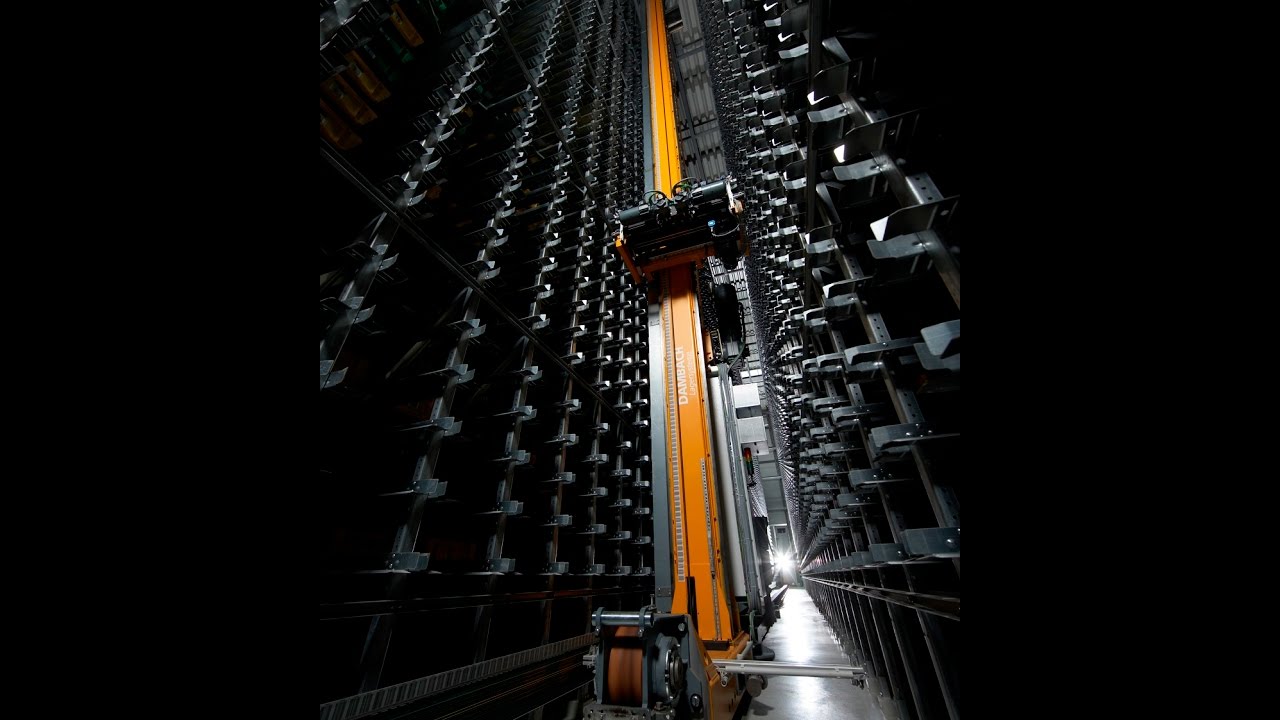

AutoStore Cubic Storage System

The facility features a flexible AutoStore system that has been expanded in multiple stages. The system currently operates with 61 robots and achieves up to 160 bin presentations per port, representing a significant improvement in throughput capacity. The AutoStore solution was selected for its superior space utilization and technology benefits.

Dark Warehouse: Fully Automated Warehouse Operations

Vendor: Addverb

Key Features

The AutoStore system's flexibility allows for staged expansion, with the capability to increase robot count and optimize port configurations as business needs evolve. The system's 160 bin presentations per port represent a significant throughput improvement, enabling faster order processing.

The integration between AutoStore and high-bay warehouse through NVision WMS creates a comprehensive automated storage solution that handles diverse product characteristics. The system is particularly well-suited for managing seasonal articles with varying turnover rates.

Results & Benefits

The automation solution has successfully expanded Weiling's capacity to support continued business growth and product range expansion. The significant improvement in bin presentation capacity has enhanced operational efficiency and throughput capabilities.

The system provides optimized space utilization, especially beneficial for handling seasonal articles with lower turnover rates. The flexible expansion capability ensures the solution can adapt to future business requirements without major system overhauls.

Challenges & Solutions

The primary challenge was managing an expanding product range that included seasonal articles with lower turnover rates, requiring a storage solution that could efficiently handle varying demand patterns. The solution came through implementing the AutoStore system, which best covers both space utilization requirements and turnover rate optimization for seasonal items.

Another challenge was ensuring the automation solution could accommodate future growth and changing requirements. This was addressed through the flexible AutoStore system design that allows for expansion in multiple stages, including increasing the number of robots and optimizing port configurations as needed.

System Integrator

Swisslog provided comprehensive planning, consulting, and implementation services, leveraging their established relationship with Weiling GmbH. During the planning and consulting phase, Swisslog demonstrated excellent communication and advisory capabilities, particularly important as automation was a new topic for the company with high need for guidance. The positive experience and satisfaction with concrete performance figures has established Swisslog as the preferred partner for future similar projects.

🖼️Project Gallery

🔧Related Technologies (6)

Dark Warehouse: Fully Automated Warehouse Operations

byAddverb

Momentum WES: Next-Generation Warehouse Execution and Control

byHoneywell Intelligrated

Swisslog AutoStore Integration and SynQ Software: Holistic Automation Platform

bySwisslog

Swisslog Vectura Pallet Stacker Crane: Energy-Efficient High-Bay AS/RS

bySwisslog

Meyer Corporation USA Cookware Distribution Center

byDaifuku

Robotic Piece-Picking for AutoStore: Integrating RightHand Robotics

byElement Logic