South West Healthcare Warrnambool Regional Logistics Distribution Centre

⭐Key Features

- •High-density cubic storage enabling a 500% increase in inventory capacity

- •Unified storage for SKUs requiring both pressurized and non-pressurized clean room handling

- •Capability to hold 6-8 weeks' worth of stock for regional healthcare facilities

- •Seamless integration with existing Oracle enterprise system for order processing

- •Ergonomic pick stations ensuring operator efficiency and picking accuracy

- •Partnership with Dematic including a comprehensive 5-year maintenance contract

📊Results & Benefits

- ✓500% increase in overall inventory capacity

- ✓Increased stock holdings by approximately $200,000 AUD

- ✓Order turnaround reduced to same-day for the base hospital and next-day for regional facilities

- ✓Significant reduction in backorders due to higher on-hand stock

- ✓Consolidation of two separate clean-room storage processes into one automated system

- ✓Elimination of manual picking errors through goods-to-person automation

🎯Challenges & Solutions

Severe space constraints in the existing storage facility, limiting stock holdings for a growing regional network of 13-14 hospitals.

Implemented the high-density Dematic AutoStore cubic storage system, which reduced the storage footprint while dramatically increasing capacity.

Complex IT integration with the existing Oracle enterprise resource planning (ERP) system.

Dematic worked in close partnership with the client through a dedicated IT project phase, maintaining clear communication to navigate complexities and achieve successful integration.

Needing to efficiently manage two distinct processes: storage for items requiring a pressurized sterile clean room and items for a non-pressurized clean room.

The space efficiency of the AutoStore allowed both sets of SKUs to be consolidated into a single, unified storage medium, simplifying operations.

📝Project Overview

Project Overview

South West Healthcare, a major regional hospital provider based in Warrnambool, Australia, undertook a critical project to modernize its supply chain for a network of 13 to 14 healthcare facilities across southwest Victoria. The existing manual warehouse operations were hampered by severe space limitations, resulting in insufficient stock levels, frequent backorders, and slow fulfillment times for essential medical supplies and linen.

The objective for the new Regional Logistics Distribution Centre (RLDC) was clear: achieve a massive boost in inventory capacity without expanding the physical footprint, dramatically improve order accuracy and turnaround times, and create a reliable, scalable logistics hub to support patient care across the region. The solution needed to integrate seamlessly with the hospital's existing Oracle IT infrastructure.

A key decision was partnering with Dematic for the implementation of an AutoStore system, supported by a five-year maintenance contract, ensuring long-term reliability and support for the regional location.

Technical Solution

Dematic AutoStore Cubic Storage System

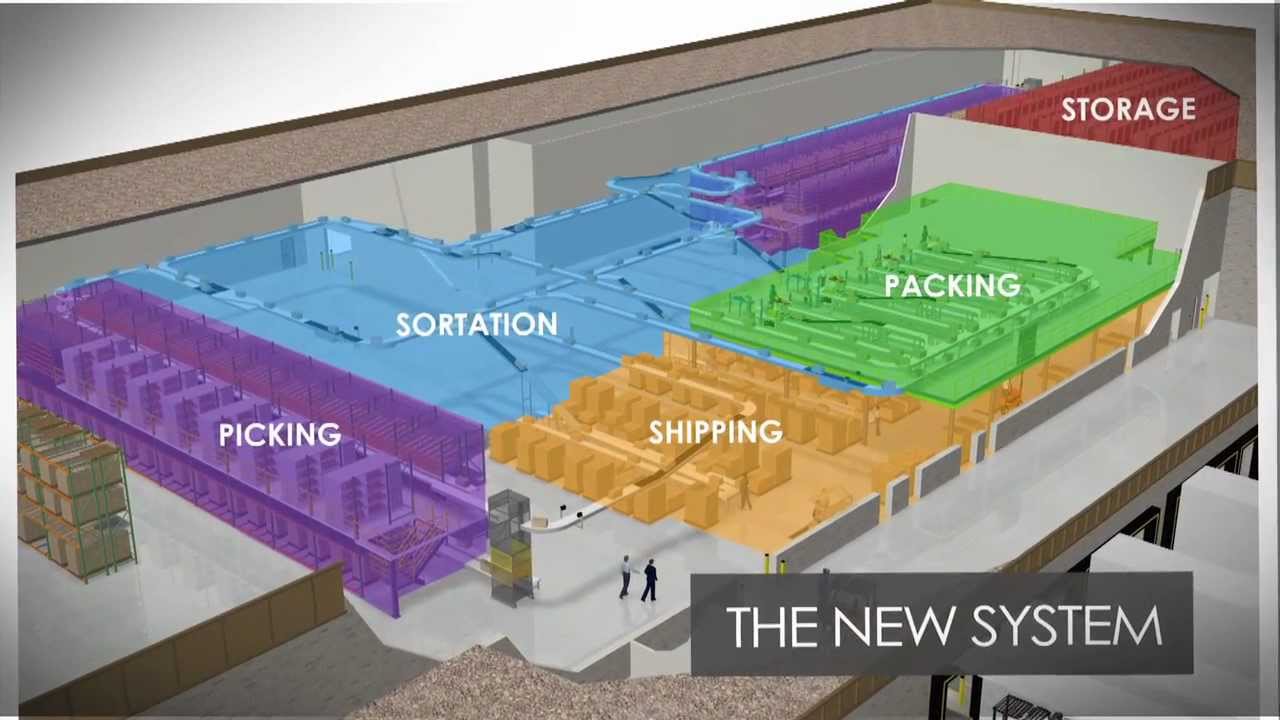

The centerpiece of the automation is a Dematic AutoStore cubic storage grid. This system utilizes vertical space efficiently by stacking 1,507 storage bins in dense columns. Robots traverse an aluminum frame grid on top, retrieving and delivering specific bins to picking stations. This high-density design was the direct answer to the site's space constraints, storing a vast inventory in a minimal footprint.

Dark Warehouse: Fully Automated Warehouse Operations

Vendor: Addverb

Key Features

The system's defining achievement is its extraordinary storage density, which facilitated a 500% increase in inventory capacity. This allows the facility to maintain a strategic buffer of 6 to 8 weeks' worth of medical and linen supplies for the entire region, greatly improving emergency readiness and supply stability.

A notable process improvement was the consolidation of inventory. Previously, items requiring a pressurized sterile clean room and those for a non-pressurized environment were stored separately. The AutoStore's compact design allowed both SKU types to be stored within the same automated system, streamlining operations. The partnership model with Dematic, including the long-term service agreement, provided the confidence needed for a critical healthcare application.

Results & Benefits

The project delivered transformative outcomes. Inventory capacity increased by 500%, and the value of on-hand stock rose by approximately $200,000 AUD. This enabled a shift in procurement strategy, allowing bulk orders every 4-6 weeks instead of weekly purchases, improving efficiency and potentially securing better pricing.

Fulfillment speed saw remarkable gains. Orders from the base hospital are now often fulfilled and ready for put-away by lunchtime on the same day they are placed. Regional facilities receive reliable next-day delivery. The accuracy of the automated system has drastically reduced backorders and eliminated manual picking errors, ensuring clinicians receive the correct supplies without delay.

Challenges & Solutions

The primary challenge was absolute space limitation, which constrained the ability to hold adequate stock for a growing regional network. The AutoStore system was selected specifically for its high-density cubic storage, which solved this by storing significantly more inventory in less space.

A significant technical hurdle was the complex integration project with the legacy Oracle ERP system. Dematic adopted a true partnership approach, working closely with the client's IT team, maintaining transparent communication about challenges and progress, which was essential to overcoming the "twists and turns" of this integration.

The operational challenge of managing two different types of clean-room inventory was resolved by the AutoStore's footprint efficiency. By freeing up space, it allowed the two previously distinct storage and handling processes to be merged into a single, automated workflow within the AutoStore grid.

System Integrator

Dematic was the end-to-end system integrator for this project. Their scope included initial consultation and design, supply and installation of the AutoStore system, complex integration with the Oracle ERP, and the provision of a five-year maintenance contract. The client praised Dematic's "partnership approach," their willingness to service a regional location, and the open, trusting relationship that was fundamental to the project's success. The final recommendation from the client was unequivocal: "Yeah, I'd recommend Dematic. Yeah, straight away it's a fantastic system, fantastic support."

🔧Related Technologies (6)

AutoStore: Robotic Cube Storage ASRS for High-Density Fulfillment

byAutoStore

Dark Warehouse: Fully Automated Warehouse Operations

byAddverb

Momentum WES: Next-Generation Warehouse Execution and Control

byHoneywell Intelligrated

AutoStore FlexBins: Multi-Size Bin System for SKU Versatility

byAutoStore

Robotic Piece-Picking for AutoStore: Integrating RightHand Robotics

byElement Logic

RapidPick XT: Goods-to-Robot Piece Picking System

byDematic