Selfar SA Thessaloniki Pharmaceutical Distribution Center

⭐Key Features

- •Two OSR Shuttle Evo aisles with 20,000 storage locations

- •Two Pick-it-Easy goods-to-person workstations

- •Two A-frame sorters with 1,900 total channels

- •Manual picking stations for maximum flexibility

- •Automated replenishment and stock balancing

- •Light-guided picking with display instructions

📊Results & Benefits

- ✓World-record system ramp-up in one week despite COVID-19

- ✓80% of order lines handled by A-frame sorters

- ✓Very short lead times for pharmacy orders

- ✓Reduced workload in manual picking stations

- ✓Faster and enhanced delivery services to customers

🎯Challenges & Solutions

COVID-19 travel restrictions during installation

Successfully achieved go-live at planned date and ramped up system in one week

Choosing between extending existing system or building second hub

Implemented second hub with OSR Shuttle Evo for maximum automation

📝Project Overview

Project Overview

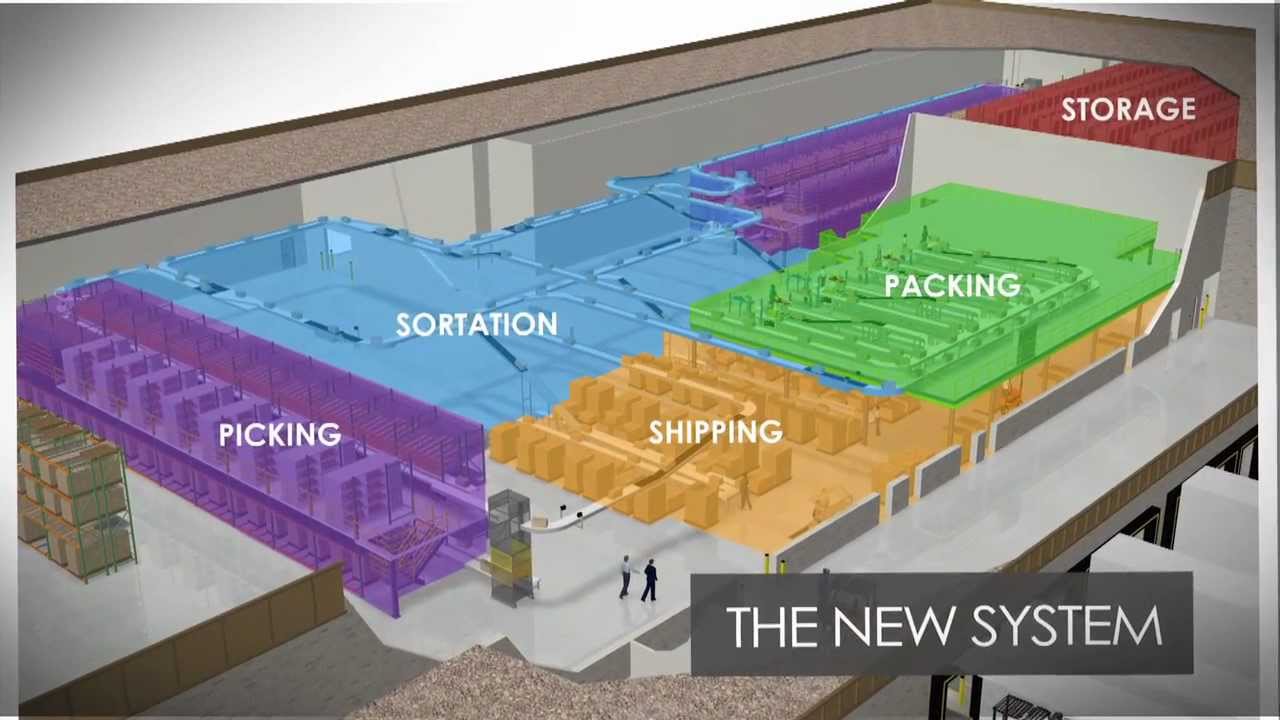

Selfar SA, an experienced pharmaceutical wholesaler in Greece, opened a brand-new ultramodern logistics center in the summer of 2020 in the west of Thessaloniki. This project represents KNAPP's 20th installation in Greece and demonstrates their long-standing partnership in the region. The facility was designed to provide faster and enhanced delivery services to Selfar SA's pharmacy customers.

The company faced a strategic decision between extending their existing system or building a second distribution hub. After thorough evaluation, they selected the second hub approach with KNAPP's OSR Shuttle Evo solution, seeking a benchmark pharmaceutical distribution system for a midsize company with reasonable investment requirements.

The project timeline was particularly challenging due to the COVID-19 pandemic, but through strong collaboration between Selfar SA and KNAPP, the system achieved go-live as planned and set a world record for ramp-up time.

Technical Solution

OSR Shuttle Evo System

The heart of the solution consists of two OSR Shuttle Evo aisles with approximately 20,000 storage locations. This shuttle system serves as the central inventory management and balancing mechanism, automatically directing storage boxes to various picking stations and replenishment points throughout the facility.

Momentum WES: Next-Generation Warehouse Execution and Control

Vendor: Honeywell Intelligrated

Key Features

The OSR Shuttle Evo system provides maximum automation on a minimum footprint, efficiently managing stock balancing and automated replenishment movements. This reduces traffic in the warehouse and optimizes order lead times through sophisticated software planning.

The A-frame sorting system's capability to handle 80% of order lines dramatically reduces manual workload and enables extremely short order processing times, allowing pharmacies to place orders later while still receiving timely deliveries.

The light-guided Pick-it-Easy workstations combine ergonomic design with error-proof picking technology, enabling operators to achieve high performance without physical movement between picking locations.

Results & Benefits

Despite COVID-19 travel restrictions, the project achieved a world-record ramp-up of just one week, demonstrating exceptional project management and collaboration between Selfar SA and KNAPP. The system went live exactly as planned.

The A-frame sorters process 80% of order lines, enabling very short lead times that allow pharmacies to place orders later in the day while still receiving prompt deliveries. This operational efficiency provides competitive advantage in pharmaceutical distribution.

Automated replenishment and reduced warehouse traffic contribute to smoother operations and lower labor requirements in manual stations, as products on the A-frame system don't require manual picking.

Challenges & Solutions

The COVID-19 pandemic created significant challenges with travel restrictions during the critical installation phase. Through strong partnership and adaptive project management, KNAPP and Selfar SA not only maintained the original go-live date but achieved a remarkable one-week ramp-up.

The strategic decision between extending existing facilities or building a new hub was resolved by implementing a second hub with the OSR Shuttle Evo solution, providing the benchmark pharmaceutical distribution system Selfar SA required for future growth.

System Integrator

KNAPP served as the system integrator, leveraging their 20 years of experience in the Greek market and 20 previous installations in the country. Their expertise in pharmaceutical automation and the strong partnership with the experienced Selfar SA team enabled the successful implementation despite global pandemic challenges. The collaboration demonstrated how experienced customers and skilled integrators can achieve exceptional results even under difficult circumstances.

🖼️Project Gallery

🔧Related Technologies (6)

Momentum WES: Next-Generation Warehouse Execution and Control

byHoneywell Intelligrated

HaiPick Climb System: Goods-to-Person Warehouse Automation

by Hai Robotics

MIX: All-round Goods-to-Person Picking Solution

byMushiny

RackBot™ Tote ASRS: Flexible Goods-to-Person Automation

byOthers

Box-IT: Ergonomic Goods-to-Person Workstation

byAddverb

Geek+ PopPick: Next-Generation High-Density Goods-to-Person System

byGeek+

📚Related Knowledge Articles (5)

Goods-to-Person Systems

Goods-to-Person (G2P) systems revolutionize warehouse operations by bringing inventory directly to stationary picking stations, eliminating worker travel time and maximizing productivity. These automated systems combine storage, retrieval, and presentation technologies to create highly efficient picking environments.

Pick-to-Light Systems

Pick-to-light systems use illuminated displays at storage locations to guide warehouse workers to the correct items and quantities, dramatically improving picking speed and accuracy.

Shuttle Systems

Shuttle systems use autonomous vehicles traveling on rails within racking structures to store and retrieve totes or cartons, providing flexible high-density automated storage with scalable throughput.

Small Load Conveyors

Small load conveyors transport individual items, totes, cartons, and packages through warehouses and distribution centers using belt, roller, or slat systems optimized for lightweight products.

Cold Storage Strategy

Cold storage and temperature-controlled warehousing are critical for preserving perishable goods throughout the supply chain. From frozen foods to pharmaceuticals, these specialized facilities maintain precise temperature conditions while optimizing energy efficiency and operational performance.