Our Curated Projects

21 projects

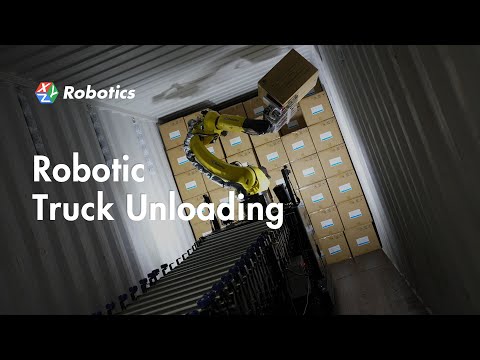

XYZ Robotics - Japanese 3PL Warehouse Robotic Truck & Container Unloading Project

XYZ Robotics deploys RockyOne Mobile Manipulation Robot to automate truck and container unloading for a Japanese 3PL warehouse, handling 15-kg cartons in 40-ft containers within 2 hours.

JD.com - Flexible Case Picking Automation with ForwardX Robotics AMRs

Global e-commerce leader JD.com partnered with ForwardX Robotics to deploy Max Series AMRs across its 1,600+ Chinese warehouses, optimizing case picking efficiency and reducing worker physical exertion.

Dexterity AI & FedEx Parcel Hub Robotic Truck Loading Project

Dexterity AI collaborates with FedEx to deploy AI-powered mobile robots for truck and trailer loading, addressing the complex challenge of stacking randomized shipments in parcel hubs.

Ariat Wholesale Footwear & Apparel Order Fulfillment Center

A wholesale footwear and apparel brand automated order consolidation with the EuroSort Twin Push Tray Sorter, integrating Exotec and Geek+ robotic picking to process up to 16,000 items per hour.

F-Line Japan Major Food Distribution Center

A high-tech food distribution center in Japan automated its entire logistics flow with multiple AS/RS, pallet shuttles, and robotic palletizing to handle 90,000 cases daily from 1.15 million in storage.

Sengkang General Hospital Singapore Central Sterile Supply Unit

A Singapore hospital transformed its surgical instrument logistics with a mini load AS/RS, vertical carousels, and robotic picking, integrated with barcode tracking and WMS/WCS to optimize the sterile supply flow.

Deli Group Ninghai Intelligent Logistics Center

China's leading office supplies manufacturer built a 110,000 sq m intelligent logistics center with a multi-system AS/RS complex, AMRs, and picking robots to process 200,000 cases daily and store 130,000 pallets.

Knuspr Germany Micro Fulfillment Center

A leading German e-grocer automated post-pick order buffering, staging, consolidation, and dispatch using Brightpick Dispatcher robots in its micro-fulfillment center to drive down costs and enable 3-hour delivery.

Home Bargains Amesbury Distribution Center

Home Bargains implemented Lowpad's AMR solution with 91 robots to automate marshalling and process 200,000 roll cages weekly, addressing recruitment challenges in remote location.

Coca-Cola Bottlers Japan Akashi Mega Distribution Center

Part of the Shinsei Project, this mega DC uses a Unit Load AS/RS, Shuttle Rack, palletizing robots, and RORO stations to handle 80 million beverage cases annually, ensuring stable supply for Osaka and Hyogo.

Netrush Kentucky E-commerce Fulfillment Warehouse

A US 3PL automated order picking and replenishment with Brightpick Retriever robots, a Goods-to-Person solution, to handle 20,000 daily orders with peaks 4-5x higher.

Cutter & Buck Seattle Apparel Fulfillment Center

Cutter & Buck deployed an AutoStore system with 34,000 bins and 54 robots, implemented by Kardex, to streamline apparel fulfillment, reduce storage footprint by 50%, and achieve order turnaround in under 10 minutes.

HiperDino - Telde Canary Islands Automated Warehouse with TGW Rovolution

Canary Islands-based HiperDino implemented TGW's FlashPick® and AI-powered Rovolution picking robot at its 50,000 m² Telde warehouse, handling 7,000 daily pallets and 5,000-10,000 tobacco cartons/day for 235 stores.

International 3PL E-commerce Warehouse with RoboShuttle

A 3PL cross-border e-commerce warehouse utilizing Geekplus RoboShuttle, the industry's tallest mobile robot, achieving 500+ units per hour picking efficiency with maximum vertical space utilization.