Knuspr Germany Micro Fulfillment Center

⭐Key Features

- •Automates order buffering, staging, consolidation, and dispatch with robots

- •Brightpick Dispatcher robots retrieve totes from conveyor for order sorting

- •Robots provide temporary storage buffer for pre-picked orders

- •Enables pre-picking during off-peak hours for dispatch during peak times

- •Complements an existing AutoStore picking system to improve overall unit economics

- •Supports rapid 3-hour grocery delivery service

📊Results & Benefits

- ✓Contributes to profitable unit economics for individual orders

- ✓Enables processing of more orders during peak hours via pre-picked buffer

- ✓Further reduces fulfillment costs beyond the initial AutoStore automation

🎯Challenges & Solutions

Achieving profitable unit economics per order with existing automation (AutoStore) alone was insufficient

Implemented Brightpick Dispatcher robots to automate the downstream order consolidation and dispatch process, driving down fulfillment costs further.

Managing order flow and efficient dispatch during peak delivery windows

Utilized Brightpick robots to create an order storage buffer, allowing pre-picking during off-peak hours and smoothing the dispatch workload.

📝Project Overview

Project Overview

Knuspr, one of Germany's fastest-growing e-grocers and part of the Rohlik Group, operates micro-fulfillment centers (MFCs) in Munich and Frankfurt. The company delivers a wide assortment of fresh, high-quality groceries to customers within a three-hour window. As part of a major European e-grocer handling over 12 million orders annually, Knuspr is focused on optimizing its fulfillment operations for speed and cost-efficiency.

While the company had already implemented an AutoStore system for automated picking, the cost savings from this system alone were not sufficient to achieve profitable unit economics for each order. To further drive down costs and streamline operations, Knuspr sought to automate the critical post-pick processes in its MFC.

The project aimed to automate the order buffering, staging, consolidation, and final dispatch process using a flexible robotic solution, integrating seamlessly with the existing AutoStore picking workflow.

Technical Solution

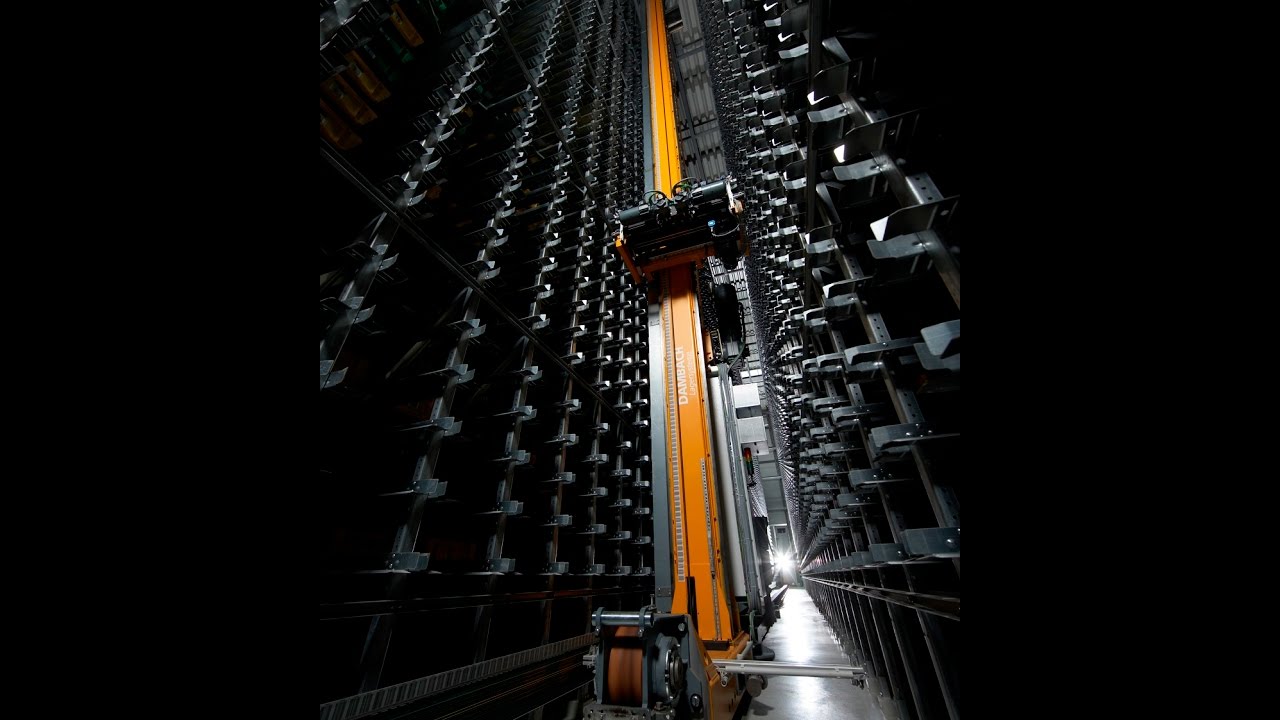

Brightpick Dispatcher Robots

The core of the solution is the Brightpick Dispatcher, an Autonomous Mobile Robot (AMR) system. These robots are deployed in the order staging and dispatch area. Their primary function is to retrieve order totes arriving via conveyor from the picking zones (including the AutoStore system) and intelligently sort them into complete customer orders ready for driver pickup.

Brightpick Autopicker: AI-Powered Robotic Picking AMR

Vendor: Brightpick

Key Features

The system automates the entire sequence after picking: buffering orders, staging them in the dispatch area, consolidating all items for a single order, and preparing them for driver collection, which minimizes manual handling and potential errors.

Brightpick Dispatcher robots autonomously retrieve order totes as they arrive on the conveyor system from various picking zones, ensuring a smooth and continuous flow of goods to the dispatch area.

The robotic buffer allows Knuspr to "pre-pick" orders during off-peak hours (e.g., early morning) and store them temporarily. When peak delivery windows arrive, these pre-picked orders can be dispatched rapidly without overloading the picking system, significantly increasing peak throughput capacity.

This solution is specifically designed to complement and enhance the efficiency of Knuspr's existing AutoStore goods-to-person picking system, creating a more cost-effective end-to-end automated workflow.

Results & Benefits

The additional automation in the dispatch process provided the necessary incremental efficiency gains and cost reductions to achieve profitable unit economics for individual grocery orders, which is critical in the low-margin e-grocery sector.

By utilizing the robotic buffer to pre-pick orders, the MFC can process and dispatch a significantly higher volume of orders during the crucial peak delivery periods (like evenings) without needing to scale picking labor proportionally.

The Brightpick automation layer delivered further reductions in fulfillment costs beyond the savings already achieved by the AutoStore system, contributing directly to the operation's overall financial sustainability.

Challenges & Solutions

A primary business challenge was that the existing AutoStore automation, while beneficial, did not lower costs enough to make each delivery order profitable on its own. Knuspr addressed this by implementing the Brightpick Dispatcher robots to automate the subsequent, labor-intensive stages of order consolidation and dispatch, extracting further cost savings from the fulfillment process.

To efficiently handle the surge of orders during short delivery windows (like 3-hour slots), Knuspr needed a way to manage workflow. The Brightpick system's buffering capability provided the solution, allowing the facility to build order inventory in advance and release it efficiently during peak times, smoothing out the operational load.

System Integrator

Brightpick provided the robotic automation solution for the post-pick process, including the Brightpick Dispatcher AMRs and the necessary software for multi-robot orchestration and workflow management within the micro-fulfillment center environment.

🔧Related Technologies (6)

AutoStore: Robotic Cube Storage ASRS for High-Density Fulfillment

byAutoStore

Autopicker: AI-Powered Mobile Picking Robot

byBrightpick

Robo-Putwall Sortation System: AMR-Powered Tilt-Bot Sorting

byOthers

Brightpick Retriever: Goods-to-Person Robots for Order Picking and Replenishment

byBrightpick

Brightpick Autopicker: AI-Powered Robotic Picking AMR

byBrightpick

AMR System: High-Density Bin-to-Person Fulfillment

byQuicktron