Our Curated Projects

35 projects

Hirschmann Automotive Rankweil Production Logistics

Hirschmann Automotive implemented a fully automated production logistics system with Servus Intralogistics, seamlessly connecting warehouse and production with 46 transport robots.

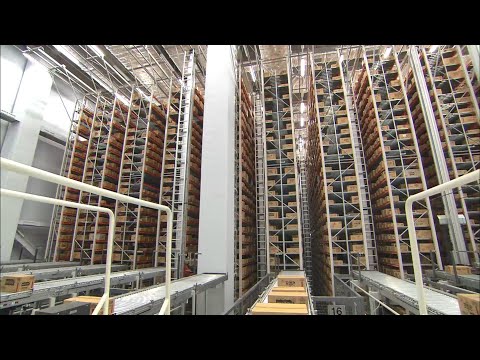

Daifuku Intralogistics India Hyderabad Manufacturing Facility

Daifuku Intralogistics India launched its first-ever 30-meter-tall stacker crane manufactured entirely in India, representing a major milestone for the Make in India initiative and local advanced intralogistics production.

MRG - Retail Distribution Center Automated Goods-to-Person Intralogistics

MRG implemented an automated goods-to-person intralogistics solution by psb at its retail distribution center, featuring 6 rotapick systems and a 6,500-container Multi Access Warehouse to optimize small parts picking efficiency.

Imbach Logistik - Luzern Logistics Center Automation

Swiss company Imbach Logistik built the Luzern Logistics Center with SSI Schaefer's automation solution, offering 130,000 container slots, 6,000+ pallet positions, and 116 pallets/hour picking rate to grow efficiently on limited space.

Bastian Solutions Corporate Profile: Toyota Advanced Logistics

Bastian Solutions, a Toyota Advanced Logistics company since 2017, leverages Toyota Production System principles like Jidoka to deliver intelligent automation and supply chain integration.

BORT Logistics Center

Viastore implemented an automated logistics center for medical technology manufacturer BORT, featuring bulk storage, picking modules, and comprehensive conveyor systems.

HAVI Lisbon Multi-Temperature Logistics Center

Mecalux delivers a multi-temperature logistics center for HAVI in Lisbon, Portugal, featuring two automated warehouses, Pallet Shuttle systems and Easy WMS integration, supporting daily supply to over 150 restaurants.

V-ZUG Kühltechnik Sulgen Refrigerator Factory

V-ZUG built a new refrigerator factory with GEBHARDT's automated logistics systems, achieving production of one refrigerator per minute with significant automation.

dm-drogerie markt Weilerswist Logistics Center Packaging Line

dm-drogerie markt deployed BEUMER stretch hood® S systems at its central distribution center, automating high-volume pallet packaging with 90 pallets per hour per line and exceptional energy efficiency.

South West Healthcare Warrnambool Regional Logistics Distribution Centre

South West Healthcare deployed a Dematic AutoStore system to boost inventory capacity by 500% for its regional medical supply network, storing 6-8 weeks of stock in a reduced footprint.

Element Logic Ireland Warehouse Automation Solutions

Element Logic Ireland provides smart, scalable warehouse automation solutions including robotic picking and high-density storage, tailored to the unique logistics challenges of the Irish market.

Lotte Korea Confectionery Centralized Distribution Center

A leading Korean confectionery producer consolidated its logistics by building a massive automated DC next to its factory, featuring ambient & freezer AS/RS and a Mini Load system to handle 25,000 cases daily.

F-Line Japan Major Food Distribution Center

A high-tech food distribution center in Japan automated its entire logistics flow with multiple AS/RS, pallet shuttles, and robotic palletizing to handle 90,000 cases daily from 1.15 million in storage.

Sengkang General Hospital Singapore Central Sterile Supply Unit

A Singapore hospital transformed its surgical instrument logistics with a mini load AS/RS, vertical carousels, and robotic picking, integrated with barcode tracking and WMS/WCS to optimize the sterile supply flow.