AGV Tugger

AGV tuggers are automated guided vehicles that tow trains of carts or trailers through warehouses and manufacturing facilities, efficiently moving large volumes of materials along fixed routes.

AGV - Tugger Overview

Tugger Types

- •Light-Duty5,000-10,000 lbs

- •Medium-Duty10,000-20,000 lbs

- •Heavy-Duty20,000-30,000+ lbs

- •SpecializedIndustry-specific

Cart Types

- •Platform CartsFlat deck, versatile

- •Shelf CartsMulti-level, small parts

- •Pallet CartsPallet handling

- •Custom CartsIndustry-specific

Coupling Systems

- •AutomaticMotorized pin

- •MagneticElectromagnetic

- •MechanicalManual pin

- •Vision-GuidedCamera-based

Applications

- •Line-Side DeliveryManufacturing JIT

- •Warehouse DistributionHigh-volume transport

- •AutomotiveSequenced delivery

- •Retail DistributionStore replenishment

Key Features

- •Cart Train3-10+ carts per trip

- •Multiple StopsMilk-run routes

- •Flexible ConfigMix cart types

- •High CapacityLarge volume/trip

Key Benefits

- •Labor Reduction2-4 handlers per tugger

- •High Efficiency30-50% productivity gain

- •Consistent DeliveryPredictable schedules

- •24/7 OperationContinuous capability

How AGV Tuggers Work

AGV tuggers follow fixed routes defined by various guidance technologies. Traditional systems use magnetic tape, wire guidance, or optical sensors that follow painted lines on the floor, providing reliable, predictable paths that ensure consistent operation. More advanced systems employ laser navigation or natural feature navigation, using onboard sensors to determine position relative to facility features like walls, columns, or reflective targets, offering greater flexibility for route modifications.

The tugger connects to a train of wheeled carts using standardized coupling mechanisms—typically automatic hitches that allow the AGV to pick up and drop off cart trains without human intervention. Each cart in the train carries materials, components, or finished goods, with total train capacity often reaching several thousand pounds. The AGV's traction system provides sufficient power to accelerate, maintain speed, and brake smoothly even when pulling fully loaded trains.

Route programming defines the tugger's operational pattern, including pickup points, delivery destinations, travel paths, and timing. Many systems operate on fixed schedules, making regular loops through the facility to deliver materials to production lines or move finished goods to staging areas. Others respond to demand signals from manufacturing execution systems or warehouse control systems, adjusting routes and frequencies based on real-time needs.

Key Benefits

The primary advantage of AGV tuggers is high-volume transport efficiency. By moving multiple carts simultaneously, tuggers can transport significantly more material per trip than unit load vehicles, reducing the number of vehicles needed and minimizing traffic congestion. This efficiency is particularly valuable in operations with predictable, high-volume flows between fixed locations.

Labor savings represent a major benefit, as tuggers eliminate the need for workers to manually tow cart trains or drive tugger vehicles. In facilities running multiple shifts, a single AGV tugger can replace 2-3 full-time operators, delivering rapid return on investment while freeing workers for value-added tasks requiring human judgment and dexterity.

Consistency and reliability distinguish automated tuggers from manual operations. AGVs follow precise routes at controlled speeds, maintain regular schedules, and operate continuously without breaks or shift changes. This predictability enables better production planning and inventory management, as materials arrive exactly when needed without early or late deliveries disrupting workflows.

Safety improvements result from eliminating human-driven tugger traffic in busy facilities. AGV tuggers include comprehensive safety systems—typically laser scanners, ultrasonic sensors, and emergency stop capabilities—that detect obstacles and people in their path, automatically slowing or stopping to prevent collisions. This reduces accident risks compared to manual tugger operations, particularly in congested areas or facilities with mixed pedestrian and vehicle traffic.

Common Applications

AGV tuggers excel in several operational contexts. Manufacturing line feeding uses tuggers to deliver components, raw materials, and subassemblies to production lines on regular schedules, ensuring that workstations always have needed materials without excess inventory accumulation. The predictable delivery timing enables just-in-time manufacturing practices that reduce work-in-process inventory and improve cash flow.

Warehouse replenishment operations employ tuggers to move inventory from bulk storage to forward pick locations, maintaining stock levels without requiring workers to leave their picking zones. The automated replenishment ensures that high-velocity items remain available while minimizing the labor required for stock movement.

Cross-docking operations leverage tuggers to transport goods from receiving docks to shipping docks, moving products through the facility without intermediate storage. The automated transport reduces handling time and labor costs while maintaining the rapid throughput that cross-docking operations require.

Finished goods movement in manufacturing facilities uses tuggers to transport completed products from production lines to quality control, packaging, or shipping areas. The automated transport ensures smooth flow without production line workers needing to manage material movement, allowing them to focus on manufacturing tasks.

Implementation Considerations

Successfully deploying AGV tuggers requires careful planning across multiple dimensions. Route design is critical—paths should minimize travel distance while avoiding congestion points and providing adequate clearance for cart trains. Routes must account for the tugger's turning radius, which is significantly larger than unit load AGVs due to the trailing cart train.

Infrastructure requirements vary by guidance technology. Magnetic tape or wire guidance systems require floor preparation and installation, while laser or natural feature navigation systems need reflective targets or clear sight lines to facility features. All systems require adequate floor conditions—smooth, level surfaces free from debris or damage that could interfere with navigation or cart movement.

Cart standardization ensures compatibility across the system. Carts should have consistent coupling mechanisms, wheel types, and dimensions to enable reliable automatic pickup and drop-off. Many operations invest in purpose-designed cart fleets optimized for AGV tugger use rather than adapting existing manual carts.

Traffic management becomes important in facilities with multiple tuggers or mixed vehicle types. The control system must coordinate tugger movements to prevent conflicts at intersections, manage access to shared resources like elevators or doors, and optimize overall fleet efficiency. Advanced systems use predictive algorithms to anticipate conflicts and adjust routes proactively.

Best Practices

To maximize AGV tugger effectiveness, consider these proven strategies. Scheduled operations work well for predictable material flows, with tuggers making regular loops at defined intervals. This approach simplifies system design and provides reliable service levels that production planning can depend on.

Demand-responsive operation suits environments with variable material needs, where the control system dispatches tuggers based on real-time requests from manufacturing or warehouse systems. This flexibility prevents unnecessary trips while ensuring materials arrive when needed.

Mixed fleet strategies combine tuggers with other AGV types to optimize overall material handling. Tuggers handle high-volume flows between fixed points, while unit load AGVs or AMRs manage variable, lower-volume movements or serve locations unsuitable for cart trains.

Preventive maintenance programs ensure reliable operation through regular inspection of mechanical components, guidance systems, and safety sensors. Tuggers experience more mechanical wear than stationary equipment due to their continuous operation and the stresses of towing loaded cart trains, making proactive maintenance essential.

Technology Evolution

Modern AGV tuggers incorporate several advanced capabilities. Automatic cart coupling systems enable tuggers to pick up and drop off cart trains without human intervention, improving efficiency and enabling fully automated workflows. These systems use sensors and mechanical actuators to align with carts and engage coupling mechanisms reliably.

Fleet management software optimizes tugger operations across multiple vehicles, coordinating routes, managing battery charging, and providing real-time visibility into system performance. Advanced systems use simulation and optimization algorithms to continuously improve efficiency and adapt to changing operational conditions.

Hybrid power systems combine battery operation with opportunity charging or battery swapping to enable continuous operation without extended charging downtime. Some systems use inductive charging at designated locations along routes, automatically recharging batteries during brief stops without requiring manual intervention.

Measuring Success

Key performance indicators for AGV tugger systems include trips per hour, material delivery reliability, vehicle utilization rates, and system uptime. These metrics help assess whether tuggers meet operational requirements and identify optimization opportunities.

Return on investment typically materializes over 2-4 years through labor savings, improved material flow efficiency, and reduced accident costs. The predictable operating costs and long equipment lifespan—often 10+ years with proper maintenance—create favorable long-term economics.

Safety performance should show measurable improvements compared to manual tugger operations, with reduced accident rates and severity. Monitoring near-miss incidents and safety system activations helps identify areas where route design or traffic management could be improved.

By implementing AGV tuggers with careful attention to route design, infrastructure requirements, and operational integration, facilities can create efficient, reliable material transport systems that reduce labor costs, improve safety, and enable more predictable operations. The technology's proven track record and continuous evolution ensure it remains a valuable tool for high-volume material movement in modern warehouses and manufacturing facilities.

🔧Related Technologies (6)

Momentum WES: Next-Generation Warehouse Execution and Control

byHoneywell Intelligrated

MIX: All-round Goods-to-Person Picking Solution

byMushiny

AMR/AGV Tuggers: Autonomous Towing for Trailers and Trolleys

by VisionNav Robotics

Tugger AGV: High-Capacity Automated Tugger for Indoor and Outdoor Transport

byOthers

AGV Systems: Custom Turnkey Tugger Solutions

byROBOS

Automated Guided Vehicle (AGV) Systems: Safety-First Automation

byJungheinrich

📚Related Transport Topics

About This Topic

📁Related Projects(6)

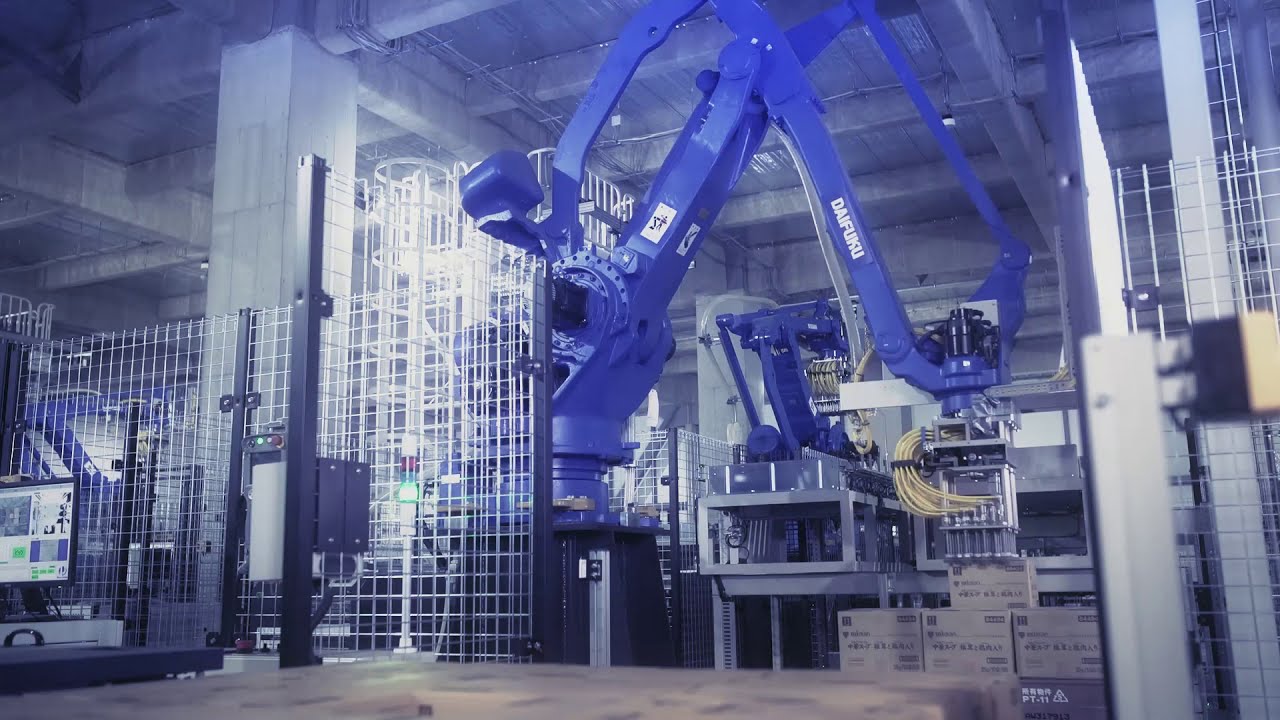

F-Line Japan Major Food Distribution Center

Daifuku

Bastian Solutions Corporate Profile: Toyota Advanced Logistics

Bastian Solutions

Hirschmann Automotive Rankweil Production Logistics

Servus Intralogistics

Coca-Cola Bottlers Japan Akashi Mega Distribution Center

Daifuku

Deli Group Ninghai Intelligent Logistics Center

Daifuku

Lao Gan Ma Guiyang Guizhou Production Warehouse

Daifuku

🏢Related Suppliers(3)

6 River Systems

The Seamless Fulfillment Automation Solution to Boost Efficiency and Productivity in Your Warehouse

Addverb

Warehouse Automation that delivers value!

Ancra Systems

Efficient Loading