Pallet Racking Systems: Configurable Warehouse Storage Solutions

⚡Quick Facts

Technology Performance Metrics

⭐Key Features

✨Benefits

🎯Applications

📝Detailed Information

Technology Overview

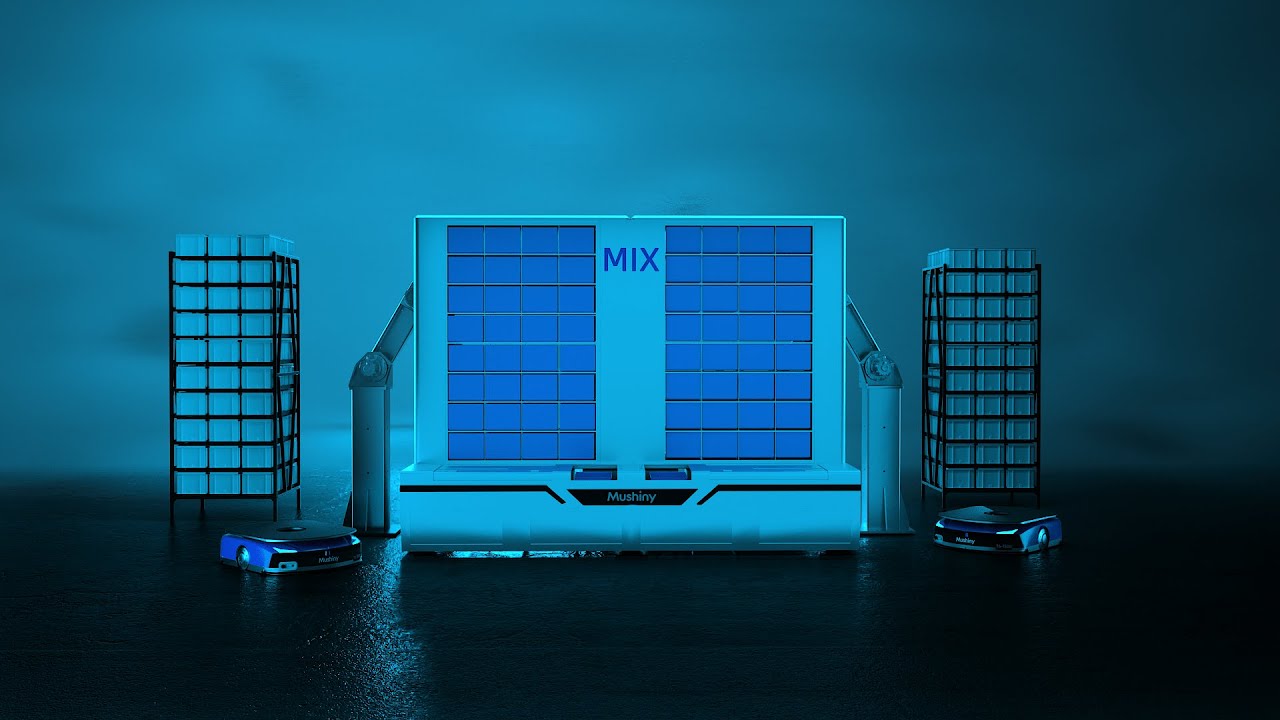

Pallet racking systems form the fundamental backbone of organized storage in warehouses and distribution centers worldwide. Unlike a one-size-fits-all product, modern pallet racking is a highly adaptable family of storage solutions. The core value proposition lies in its configurability; systems can be engineered and arranged in numerous ways to align precisely with a facility's unique operational requirements, inventory characteristics (such as pallet size and weight), and desired material flow. This approach, championed by suppliers like Dexion - Gonvarri Material Handling, ensures the creation of a functional, logical, and efficient storage environment, whether using standard selective racking for accessibility or mobile racking for maximum density.

How It Works

Core Principles

The core principle is modular design and configuration. Standardized components (uprights, beams, bracing) are assembled into structures that can vary in height, depth, bay width, and layout to create a storage system that matches the specific profile of the palletized goods and the capabilities of the material handling equipment.

Key Features & Capabilities

High Configurability is the paramount feature, allowing the system layout, beam levels, and rack type to be tailored. Adaptability to Pallet Load ensures the structural design meets the specific weight and dimensions of the unit loads. Range of Solutions encompasses everything from basic selective racking to space-optimized mobile racking, providing options for different density and access needs.

Advantages & Benefits

The primary advantage is the ability to design a perfectly fitting storage solution, maximizing both space utilization and operational efficiency for a given operation. This leads to a logical and functional warehouse layout that smooths workflows and reduces travel time. The inherent flexibility and scalability of modular racking allow the system to evolve alongside the business. Choosing a configured solution from an expert provider ensures engineering integrity and safety.

Implementation Considerations

Successful implementation requires a thorough needs analysis, including data on pallet specs, inventory turnover (SKU velocity), available space, and forklift types. The decision between standard and high-density mobile racking involves balancing the need for immediate access to all SKUs against the requirement for maximum storage density. Professional design and planning are crucial to avoid under or over-utilization of space.

Use Cases & Applications

Ideal For

This concept is ideal for any business storing palletized goods that seeks a storage system not "off-the-shelf" but engineered to fit its specific operational reality and growth plans.

Conclusion

Pallet racking is far more than just shelves for pallets; it is a customizable storage technology that can be precisely configured to power warehouse efficiency. By partnering with a knowledgeable supplier to analyze needs and design an appropriate system—be it standard, mobile, or a hybrid—businesses can create a logical, functional, and scalable storage foundation. This tailored approach ensures that the storage solution is an asset that drives productivity, optimizes valuable space, and adapts to future challenges, making it a critical strategic investment for any logistics operation.