Our Curated Projects

19 projects

Ospelt Food Sargans Cold Storage Automation

Ospelt Food implemented GEBHARDT's AGV system to optimize pallet transport to cold storage while maintaining the critical cold chain in food production.

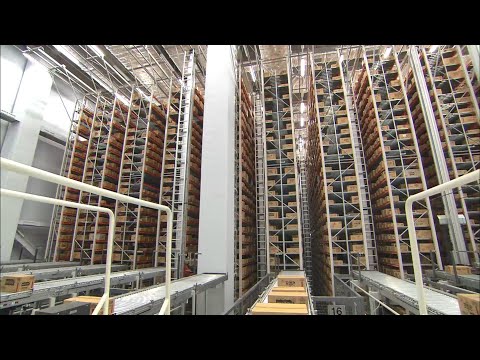

F-Line Japan Major Food Distribution Center

A high-tech food distribution center in Japan automated its entire logistics flow with multiple AS/RS, pallet shuttles, and robotic palletizing to handle 90,000 cases daily from 1.15 million in storage.

Weiling GmbH Coesfeld Distribution Center

A leading German organic food wholesaler implemented AutoStore system and high-bay warehouse to expand capacity and manage growing product range with flexible automation.

Agile Cold Storage Distribution Center

Third-party cold storage facility tripling pallet capacity to 48,000 in 110,000 sq ft using Swisslog ASRS with SynQ software, serving food manufacturers and global export markets.

LIEKEN High Bay Cold Store for Baked Goods

A high bay cold store for bread and baked goods with a capacity of 6,000 pallets at -24°C, using DAMBACH Storage and Retrieval Machines to achieve 4,296 pallet movements daily.

Lotte Korea Confectionery Centralized Distribution Center

A leading Korean confectionery producer consolidated its logistics by building a massive automated DC next to its factory, featuring ambient & freezer AS/RS and a Mini Load system to handle 25,000 cases daily.

Lao Gan Ma Guiyang Guizhou Production Warehouse

The iconic Chinese chili sauce brand automated its production logistics with a large-scale Unit Load AS/RS, palletizing robots, and STVs to connect 7 lines across 6 factories, achieving high inbound/outbound throughput.

Vinamilk Saigon Dairy Factory Cold Storage Warehouse

Vietnam's leading dairy producer implemented a cold-environment Automated Storage and Retrieval System (AS/RS) that quadrupled storage capacity while enhancing efficiency and quality control in its logistics operations.

Bee Sweet Citrus California Palletizing Facility

Bee Sweet Citrus implemented Honeywell Intelligrated's automated palletizing solution to handle diverse citrus packaging with 125 trucks daily from their 400,000 sq ft campus.

JJCL Multi-Zone Cold Chain Automation

World's first multi-zone pallet-handling system for deep-freeze automation, automating frozen-to-chilled zone movement with zero manual transfers.

BevChain Australia Distribution Center

Australia's first high-density PowerStore system increasing pallet storage capacity by 60% in the same footprint, handling over 30,000 pallet locations across five levels.

HAVI Lisbon Multi-Temperature Logistics Center

Mecalux delivers a multi-temperature logistics center for HAVI in Lisbon, Portugal, featuring two automated warehouses, Pallet Shuttle systems and Easy WMS integration, supporting daily supply to over 150 restaurants.