Our Curated Projects

30 projects

Ospelt Food Sargans Cold Storage Automation

Ospelt Food implemented GEBHARDT's AGV system to optimize pallet transport to cold storage while maintaining the critical cold chain in food production.

F-Line Japan Major Food Distribution Center

A high-tech food distribution center in Japan automated its entire logistics flow with multiple AS/RS, pallet shuttles, and robotic palletizing to handle 90,000 cases daily from 1.15 million in storage.

Agile Cold Storage Distribution Center

Third-party cold storage facility tripling pallet capacity to 48,000 in 110,000 sq ft using Swisslog ASRS with SynQ software, serving food manufacturers and global export markets.

Coles Redbank Automated Distribution Center

Coles' largest capital investment in 109 years: a 66,000 sqm automated distribution center in Redbank processing 4 million cases weekly for 219 supermarkets.

The Feed Sports Nutrition Automated Fulfillment Center with Brightpick

An AI-powered e-commerce fulfillment center operated by 48 Brightpick Autopicker robots, processing 50,000 items daily with 24/7 operations for a leading sports nutrition retailer.

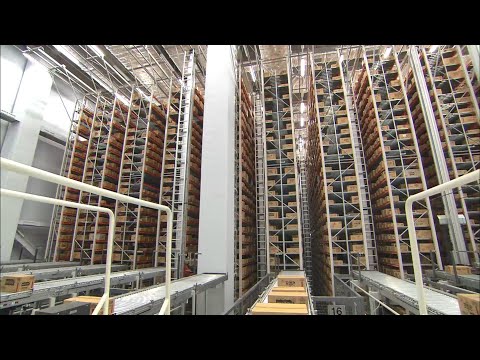

MULTIFLEX Pallet Warehouse: High-Density Frozen Storage

A high-bay automated warehouse system using shuttle operation in storage channels to achieve maximum pallet capacity and high throughput, specifically implemented for frozen goods storage.

Lotte Korea Confectionery Centralized Distribution Center

A leading Korean confectionery producer consolidated its logistics by building a massive automated DC next to its factory, featuring ambient & freezer AS/RS and a Mini Load system to handle 25,000 cases daily.

Coca-Cola Bottlers Japan Akashi Mega Distribution Center

Part of the Shinsei Project, this mega DC uses a Unit Load AS/RS, Shuttle Rack, palletizing robots, and RORO stations to handle 80 million beverage cases annually, ensuring stable supply for Osaka and Hyogo.

Vinamilk Saigon Dairy Factory Cold Storage Warehouse

Vietnam's leading dairy producer implemented a cold-environment Automated Storage and Retrieval System (AS/RS) that quadrupled storage capacity while enhancing efficiency and quality control in its logistics operations.

Snack Brands Australia Sydney Distribution Center

Snack Brands consolidated two warehouses into a 30,255 sqm facility with Daifuku's high-bay AS/RS, achieving fully automated distribution for iconic snack brands.

JJCL Multi-Zone Cold Chain Automation

World's first multi-zone pallet-handling system for deep-freeze automation, automating frozen-to-chilled zone movement with zero manual transfers.

Trinchero Family Estates Napa Valley Winery

A complete winery facility featuring automated PowerStore system handling 22 million cases annually with 100% inventory accuracy and 27-minute order staging.

HAVI Lisbon Multi-Temperature Logistics Center

Mecalux delivers a multi-temperature logistics center for HAVI in Lisbon, Portugal, featuring two automated warehouses, Pallet Shuttle systems and Easy WMS integration, supporting daily supply to over 150 restaurants.

Ariat Wholesale Footwear & Apparel Order Fulfillment Center

A wholesale footwear and apparel brand automated order consolidation with the EuroSort Twin Push Tray Sorter, integrating Exotec and Geek+ robotic picking to process up to 16,000 items per hour.