Our Curated Projects

20 projects

Gleaners Food Bank Indianapolis Back Sack Assembly Line

Gleaners Food Bank collaborated with Bastian Solutions to automate its Back Sack assembly line, expanding the weekend meal program from 3,000 to 10,000 children weekly.

Ospelt Food Sargans Cold Storage Automation

Ospelt Food implemented GEBHARDT's AGV system to optimize pallet transport to cold storage while maintaining the critical cold chain in food production.

Coles Redbank Automated Distribution Center

Coles' largest capital investment in 109 years: a 66,000 sqm automated distribution center in Redbank processing 4 million cases weekly for 219 supermarkets.

Agile Cold Storage Distribution Center

Third-party cold storage facility tripling pallet capacity to 48,000 in 110,000 sq ft using Swisslog ASRS with SynQ software, serving food manufacturers and global export markets.

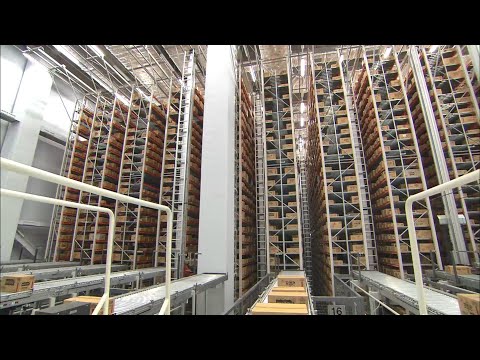

MULTIFLEX Pallet Warehouse: High-Density Frozen Storage

A high-bay automated warehouse system using shuttle operation in storage channels to achieve maximum pallet capacity and high throughput, specifically implemented for frozen goods storage.

LIEKEN High Bay Cold Store for Baked Goods

A high bay cold store for bread and baked goods with a capacity of 6,000 pallets at -24°C, using DAMBACH Storage and Retrieval Machines to achieve 4,296 pallet movements daily.

Coca-Cola Bottlers Japan Akashi Mega Distribution Center

Part of the Shinsei Project, this mega DC uses a Unit Load AS/RS, Shuttle Rack, palletizing robots, and RORO stations to handle 80 million beverage cases annually, ensuring stable supply for Osaka and Hyogo.

Lao Gan Ma Guiyang Guizhou Production Warehouse

The iconic Chinese chili sauce brand automated its production logistics with a large-scale Unit Load AS/RS, palletizing robots, and STVs to connect 7 lines across 6 factories, achieving high inbound/outbound throughput.

Snack Brands Australia Sydney Distribution Center

Snack Brands consolidated two warehouses into a 30,255 sqm facility with Daifuku's high-bay AS/RS, achieving fully automated distribution for iconic snack brands.

Bee Sweet Citrus California Palletizing Facility

Bee Sweet Citrus implemented Honeywell Intelligrated's automated palletizing solution to handle diverse citrus packaging with 125 trucks daily from their 400,000 sq ft campus.

Trinchero Family Estates Napa Valley Winery

A complete winery facility featuring automated PowerStore system handling 22 million cases annually with 100% inventory accuracy and 27-minute order staging.

BevChain Australia Distribution Center

Australia's first high-density PowerStore system increasing pallet storage capacity by 60% in the same footprint, handling over 30,000 pallet locations across five levels.

DICK'S Sporting Goods Conklin Distribution Center

A 650,000 square foot distribution center featuring 7.5 miles of conveyor systems, serving up to 160 stores with improved throughput and efficiency for omnichannel retail operations.

SMC Corporation Indiana Distribution Center

A 1 million square foot distribution center featuring AutoStore goods-to-person system and pick-and-pass operation, doubling daily throughput and enabling 93% same-day shipping.