Our Curated Projects

50 projects

Lindab Automated Distribution Center

A 10,600 sqm automated distribution center with high-bay storage handling 250 pallets in/out per hour, featuring 21,500 pallet positions and achieving 50% productivity improvement.

Bruges Belgium FlashPick® Automated Warehouse System

TGW implemented a high-performance FlashPick® system in Bruges, Belgium, addressing double-digit annual growth, labor scarcity, and space constraints with modular, high-density automation.

Lidl Køge Distribution Center

Lidl's distribution center in Køge, Denmark utilizes Vanderlande's automated case picking solution with ADAPTO shuttle-based AS/RS to outperform traditional order fulfillment methods.

Element Logic Ireland Warehouse Automation Solutions

Element Logic Ireland provides smart, scalable warehouse automation solutions including robotic picking and high-density storage, tailored to the unique logistics challenges of the Irish market.

Knuspr Germany Micro Fulfillment Center

A leading German e-grocer automated post-pick order buffering, staging, consolidation, and dispatch using Brightpick Dispatcher robots in its micro-fulfillment center to drive down costs and enable 3-hour delivery.

Alza Prague High-Throughput Fulfillment Center

Alza, the largest Czech/Slovak online retailer, deployed a 300,000-bin, 580-robot AutoStore system integrated by Element Logic, achieving 75% faster picking and handling up to 260,000 daily orders.

Autumn Ocean Conveyor - Oakland Manufacturing Facility Omnichannel Fulfillment Automation

Autumn Ocean Conveyor's Oakland, Illinois manufacturing facility implemented Wind Right's Wind Soft solution with voice-directed technology and barcode scanners to automate inventory processes, improving accuracy and efficiency for omnichannel fulfillment.

Balluff Inc. Sensor Solutions Automated Warehouse

Balluff Inc. achieved a 177% throughput increase with an AutoStore system implemented by Kardex, featuring an innovative cross-building design installed in just 6 months.

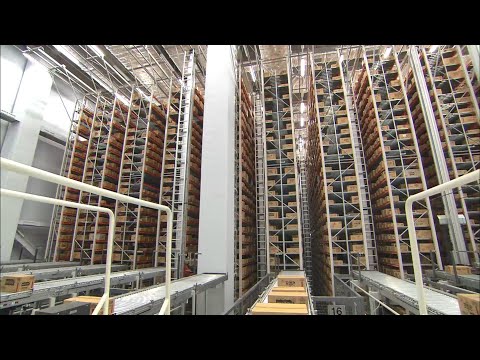

Amway Midwest Regional Service Center, Ada

Amway streamlined its Midwest fulfillment, moving to a new automated facility 50% smaller yet capable of handling over 30,000 cartons daily, achieving faster order fulfillment and reduced costs.

Walmart - Next Generation Fulfillment Centers Automation

Walmart partnered with KNAPP to deploy next-generation fulfillment centers featuring Evo 2D Shuttle ASRS, doubling storage capacity and streamlining 12-step processes into 5 steps for omnichannel retail.

Lotte Korea Confectionery Centralized Distribution Center

A leading Korean confectionery producer consolidated its logistics by building a massive automated DC next to its factory, featuring ambient & freezer AS/RS and a Mini Load system to handle 25,000 cases daily.

Deli Group Ninghai Intelligent Logistics Center

China's leading office supplies manufacturer built a 110,000 sq m intelligent logistics center with a multi-system AS/RS complex, AMRs, and picking robots to process 200,000 cases daily and store 130,000 pallets.

F-Line Japan Major Food Distribution Center

A high-tech food distribution center in Japan automated its entire logistics flow with multiple AS/RS, pallet shuttles, and robotic palletizing to handle 90,000 cases daily from 1.15 million in storage.

Sengkang General Hospital Singapore Central Sterile Supply Unit

A Singapore hospital transformed its surgical instrument logistics with a mini load AS/RS, vertical carousels, and robotic picking, integrated with barcode tracking and WMS/WCS to optimize the sterile supply flow.