Our Curated Projects

50 projects

The Feed Sports Nutrition Automated Fulfillment Center with Brightpick

An AI-powered e-commerce fulfillment center operated by 48 Brightpick Autopicker robots, processing 50,000 items daily with 24/7 operations for a leading sports nutrition retailer.

Home Bargains Amesbury Distribution Center

Home Bargains implemented Lowpad's AMR solution with 91 robots to automate marshalling and process 200,000 roll cages weekly, addressing recruitment challenges in remote location.

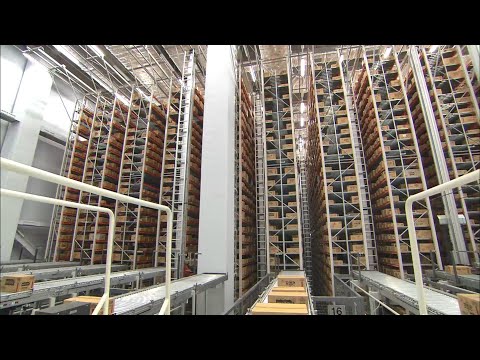

MULTIFLEX Pallet Warehouse: High-Density Frozen Storage

A high-bay automated warehouse system using shuttle operation in storage channels to achieve maximum pallet capacity and high throughput, specifically implemented for frozen goods storage.

Lotte Korea Confectionery Centralized Distribution Center

A leading Korean confectionery producer consolidated its logistics by building a massive automated DC next to its factory, featuring ambient & freezer AS/RS and a Mini Load system to handle 25,000 cases daily.

F-Line Japan Major Food Distribution Center

A high-tech food distribution center in Japan automated its entire logistics flow with multiple AS/RS, pallet shuttles, and robotic palletizing to handle 90,000 cases daily from 1.15 million in storage.

Vinamilk Saigon Dairy Factory Cold Storage Warehouse

Vietnam's leading dairy producer implemented a cold-environment Automated Storage and Retrieval System (AS/RS) that quadrupled storage capacity while enhancing efficiency and quality control in its logistics operations.

Netrush Kentucky E-commerce Fulfillment Warehouse

A US 3PL automated order picking and replenishment with Brightpick Retriever robots, a Goods-to-Person solution, to handle 20,000 daily orders with peaks 4-5x higher.

Rohlik.cz Prague Fulfillment Center

Rohlik Group automated its Prague e-grocery fulfillment center with Brightpick Dispatcher robots for intelligent order consolidation and dispatch, smoothing daily picking volumes.

Amway Midwest Regional Service Center, Ada

Amway streamlined its Midwest fulfillment, moving to a new automated facility 50% smaller yet capable of handling over 30,000 cartons daily, achieving faster order fulfillment and reduced costs.

V-ZUG Kühltechnik Sulgen Refrigerator Factory

V-ZUG built a new refrigerator factory with GEBHARDT's automated logistics systems, achieving production of one refrigerator per minute with significant automation.

Snack Brands Australia Sydney Distribution Center

Snack Brands consolidated two warehouses into a 30,255 sqm facility with Daifuku's high-bay AS/RS, achieving fully automated distribution for iconic snack brands.

Bee Sweet Citrus California Palletizing Facility

Bee Sweet Citrus implemented Honeywell Intelligrated's automated palletizing solution to handle diverse citrus packaging with 125 trucks daily from their 400,000 sq ft campus.

Hirschmann Automotive Rankweil Production Logistics

Hirschmann Automotive implemented a fully automated production logistics system with Servus Intralogistics, seamlessly connecting warehouse and production with 46 transport robots.

BORT Logistics Center

Viastore implemented an automated logistics center for medical technology manufacturer BORT, featuring bulk storage, picking modules, and comprehensive conveyor systems.