Our Curated Projects

57 projects

Körber ErgoUnload Parcel Unloading System

Körber's ErgoUnload system provides ergonomic trailer unloading solution that increases throughput to 3,000 parcels per hour while reducing physical effort by 90%.

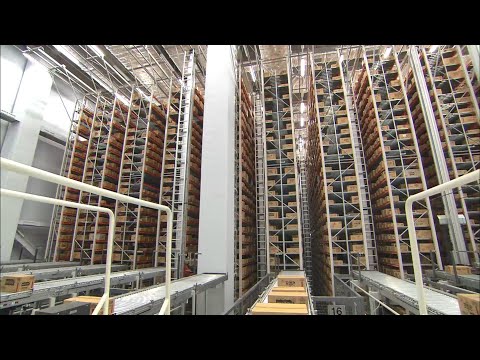

Sengkang General Hospital Singapore Central Sterile Supply Unit

A Singapore hospital transformed its surgical instrument logistics with a mini load AS/RS, vertical carousels, and robotic picking, integrated with barcode tracking and WMS/WCS to optimize the sterile supply flow.

Lao Gan Ma Guiyang Guizhou Production Warehouse

The iconic Chinese chili sauce brand automated its production logistics with a large-scale Unit Load AS/RS, palletizing robots, and STVs to connect 7 lines across 6 factories, achieving high inbound/outbound throughput.

Carter's / OshKosh USA Distribution Center

The children's apparel brand boosted distribution efficiency with Element Logic's high-speed unit sortation technology, enabling precise handling of thousands of units for retail and e-commerce orders.

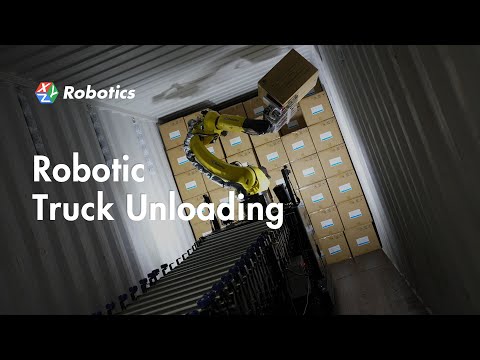

XYZ Robotics - Japanese 3PL Warehouse Robotic Truck & Container Unloading Project

XYZ Robotics deploys RockyOne Mobile Manipulation Robot to automate truck and container unloading for a Japanese 3PL warehouse, handling 15-kg cartons in 40-ft containers within 2 hours.

Dexterity AI & FedEx Parcel Hub Robotic Truck Loading Project

Dexterity AI collaborates with FedEx to deploy AI-powered mobile robots for truck and trailer loading, addressing the complex challenge of stacking randomized shipments in parcel hubs.

SHAKE-HAND - Belgian Standard Elements Automated Storage

SHAKE-HAND implemented Kardex Miniload-in-a-Box systems including extended VBM units to replace manual storage, doubling capacity and reducing picking errors for machine builder distribution.

San Francisco International Airport Harvey Milk Terminal 1 Baggage Handling System

SFO partnered with BEUMER Group to deploy the United States' first Individual Carrier System (ICS) baggage handling system, enhancing efficiency and security in the new terminal.

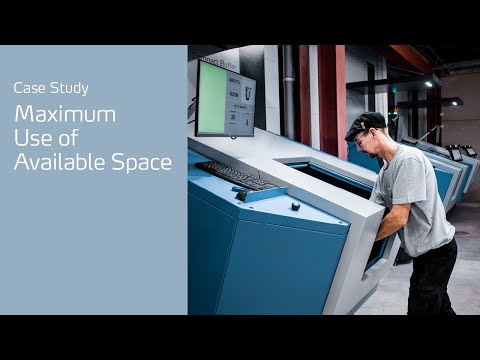

International 3PL E-commerce Warehouse with RoboShuttle

A 3PL cross-border e-commerce warehouse utilizing Geekplus RoboShuttle, the industry's tallest mobile robot, achieving 500+ units per hour picking efficiency with maximum vertical space utilization.

Agile Cold Storage Distribution Center

Third-party cold storage facility tripling pallet capacity to 48,000 in 110,000 sq ft using Swisslog ASRS with SynQ software, serving food manufacturers and global export markets.

Peterbilt - ASRS Aisle 4 Retrofit Project

Peterbilt retrofitted ASRS Aisle 4 to increase storage capacity for large integral cab sleeper units, completed 6 weeks early with no production disruptions by Daifuku.

Medline Industries Healthcare Distribution Center

First US deployment of Swisslog AutoStore system achieving 1,000 picks per hour per person, five times faster than traditional manual picking for healthcare supply distribution.

UK Mail - Purpose-Built Automated Parcel Sortation Hub

UK Mail partnered with BEUMER Group to build a future-ready automated parcel sortation hub, featuring two LS-4000CB cross-belt sorters and scalable design to support ongoing e-commerce-driven growth.

Deli Group Ninghai Intelligent Logistics Center

China's leading office supplies manufacturer built a 110,000 sq m intelligent logistics center with a multi-system AS/RS complex, AMRs, and picking robots to process 200,000 cases daily and store 130,000 pallets.