Our Curated Projects

50 projects

FIEGE Apfelstädt Logistics Center AutoStore System

The logistics service provider FIEGE implemented one of Germany's largest AutoStore systems, integrated with the SuPCIS-L8 WMS, to automate small parts storage and process control at its Apfelstädt center.

MRG - Retail Distribution Center Automated Goods-to-Person Intralogistics

MRG implemented an automated goods-to-person intralogistics solution by psb at its retail distribution center, featuring 6 rotapick systems and a 6,500-container Multi Access Warehouse to optimize small parts picking efficiency.

Deli Group Ninghai Intelligent Logistics Center

China's leading office supplies manufacturer built a 110,000 sq m intelligent logistics center with a multi-system AS/RS complex, AMRs, and picking robots to process 200,000 cases daily and store 130,000 pallets.

BORT Logistics Center

Viastore implemented an automated logistics center for medical technology manufacturer BORT, featuring bulk storage, picking modules, and comprehensive conveyor systems.

HAVI Lisbon Multi-Temperature Logistics Center

Mecalux delivers a multi-temperature logistics center for HAVI in Lisbon, Portugal, featuring two automated warehouses, Pallet Shuttle systems and Easy WMS integration, supporting daily supply to over 150 restaurants.

Hirschmann Automotive Rankweil Production Logistics

Hirschmann Automotive implemented a fully automated production logistics system with Servus Intralogistics, seamlessly connecting warehouse and production with 46 transport robots.

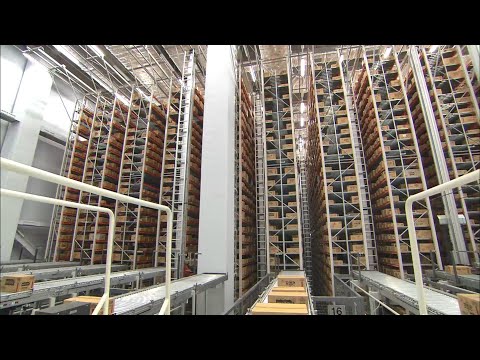

Daifuku Intralogistics India Hyderabad Manufacturing Facility

Daifuku Intralogistics India launched its first-ever 30-meter-tall stacker crane manufactured entirely in India, representing a major milestone for the Make in India initiative and local advanced intralogistics production.

F-Line Japan Major Food Distribution Center

A high-tech food distribution center in Japan automated its entire logistics flow with multiple AS/RS, pallet shuttles, and robotic palletizing to handle 90,000 cases daily from 1.15 million in storage.

PUMA - Geiselwind Multi-Channel Automated Distribution Center

PUMA’s highly-automated distribution center in Geiselwind, Germany, uses TGW’s FlashPick® system (700,000 storage locations) to dispatch 74 million items/year with 10-minute order-to-issue time, serving retail and wholesale channels.

CEWE Stiftung - Oldenburg Production & Distribution Center Automation

psb intralogistics implemented a dynamic pouch sorter and lying goods conveyor system at CEWE Stiftung's Oldenburg facility, handling 2,500 order lines/hour and 4,000 single orders/hour to optimize multi-item order consolidation and shipping efficiency.

Lotte Korea Confectionery Centralized Distribution Center

A leading Korean confectionery producer consolidated its logistics by building a massive automated DC next to its factory, featuring ambient & freezer AS/RS and a Mini Load system to handle 25,000 cases daily.

Knuspr Germany Micro Fulfillment Center

A leading German e-grocer automated post-pick order buffering, staging, consolidation, and dispatch using Brightpick Dispatcher robots in its micro-fulfillment center to drive down costs and enable 3-hour delivery.

Calzedonia Group Italian Distribution Center Pouch System

Calzedonia Group implemented BEUMER Group's BG Pouch System to expand fulfillment and returns capacity within its existing Italian distribution center, saving floor space with a ceiling-mounted design.

Bastian Solutions Corporate Profile: Toyota Advanced Logistics

Bastian Solutions, a Toyota Advanced Logistics company since 2017, leverages Toyota Production System principles like Jidoka to deliver intelligent automation and supply chain integration.