Mini-Load AS/RS: High-Speed, Space-Optimized Automation for Small Loads

⚡Quick Facts

Technology Performance Metrics

⭐Key Features

✨Benefits

🎯Applications

📝Detailed Information

Technology Overview

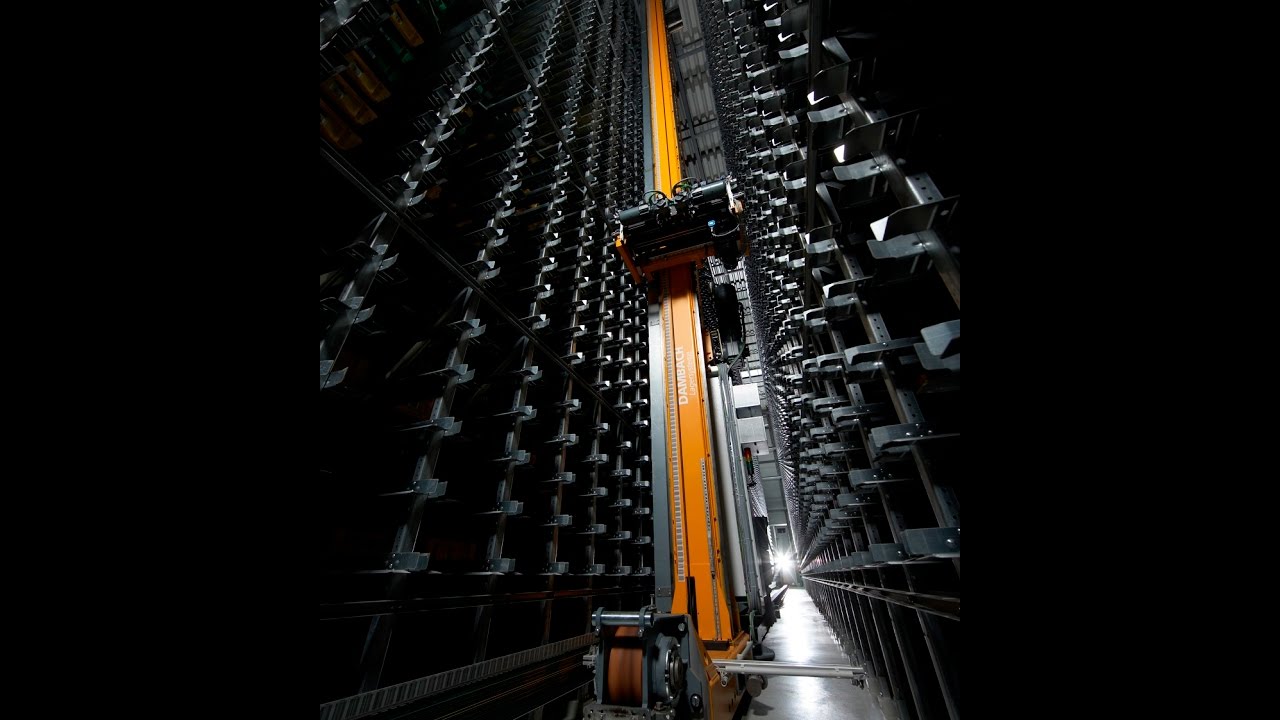

The Mini-Load Automated Storage and Retrieval System (AS/RS) is a transformative automation solution designed for the efficient handling of small unit loads in modern logistics and manufacturing. It addresses the critical challenges of space optimization and operational speed in warehouses, factories, and distribution centers. This system is notably versatile, capable of storing not only standard containers, cartons, and trays but also unconventional circular items like paper rolls or car wheels. At its core is a high-speed, precise, and quiet stacker crane that automates the storage and retrieval process. A key strength is its ability to maximize vertical cubic space, dramatically increasing storage capacity—a vital feature where floor space is limited. Furthermore, its adaptability extends to various environmental conditions, including ambient, chilled, and frozen storage, making it a comprehensive solution for industries ranging from general merchandise to food and beverage.

How It Works

Core Principles

The system operates on the principle of automated, high-density vertical storage. A computer-controlled stacker crane operates within a narrow aisle of multi-level racking, automatically storing incoming loads in assigned locations and retrieving specific items on demand based on commands from a warehouse control system (WCS).

Key Features & Capabilities

Exceptional Load Variety and Handling Flexibility is a standout feature. Beyond standard totes, the system can be equipped with custom load handlers (forks, clamps, cradle arms) to securely manage diverse items, including rolls and wheels, making it applicable to niche industries like paper, tire, or automotive parts storage.

High-Speed, Precision Operation with Low Noise defines its performance. The stacker crane is engineered for rapid acceleration and deceleration, ensuring short cycle times. Its quiet electric operation allows for installation in noise-sensitive areas, such as mezzanines above offices or in multi-use facilities.

Environmental Adaptability for Cold Chain is a critical capability. The system is designed to operate reliably in freezer and chilled environments, supporting the automated storage and retrieval of fresh and frozen food products for piece-picking operations, which is a significant advantage for grocery and food service distribution.

Advantages & Benefits

The primary advantage is massive gains in storage density and space utilization. By building upwards, it can often double or triple effective storage capacity within the same footprint, delaying costly expansions and maximizing return on real estate.

It dramatically accelerates order picking and material supply. By delivering items directly to an ergonomic picking station (goods-to-person), it eliminates worker travel and search time, increasing pick rates by multiples while simultaneously reducing physical strain and fatigue on employees.

The system enhances operational efficiency and inventory control across diverse applications. Whether serving as a dynamic buffer for manufacturing work-in-process, a secure inventory supply for order fulfillment, or the backbone of a cold storage picking operation, it brings accuracy, speed, and traceability to core processes.

Implementation Considerations

Thorough analysis of the item mix and handling requirements is essential. The success of handling non-standard items like rolls or wheels depends on precise engineering of the load-handling device, which must be factored into the design phase.

Facility assessment for vertical expansion is crucial. Implementing a high-density system requires adequate ceiling height and floor load capacity. For installations on upper floors or in cold environments, additional structural and insulation considerations apply.

Integration with existing workflows and systems (WMS, ERP, production control) is key to realizing the full value. The system should not be an island but a seamlessly integrated component of the broader operational ecosystem.

Use Cases & Applications

Ideal For

This system is ideal for e-commerce fulfillment centers, manufacturing plants with kitting or sequencing needs, food distribution centers (including frozen), and any operation storing a high variety of small to medium-sized items where space, speed, and accuracy are pressing concerns.

Performance Metrics

While specific numerical throughput is not provided, the content emphasizes qualitative performance gains: significant increase in storage capacity through vertical space use, high-speed and precise operation, and the ability to speed up order picking by reducing search time.

Conclusion

The Daifuku Mini-Load AS/RS represents a mature, highly adaptable, and powerful form of automation for handling small loads. Its ability to conquer vertical space, handle an unusual variety of items, operate quietly, and function in harsh environments makes it a uniquely versatile solution. For businesses facing space constraints, labor challenges, or the need to automate complex handling tasks—especially in food or manufacturing—this system offers a proven path to greater density, efficiency, and control. Implementing such a system is a significant undertaking that benefits greatly from the deep experience of providers like Daifuku. A successful project requires careful planning around product handling, facility integration, and workflow design to fully harness its potential for transforming storage and retrieval operations.

📦Related Projects

Lotte Korea Confectionery Centralized Distribution Center

A leading Korean confectionery producer consolidated its logistics by building a massive automated DC next to its factory, featuring ambient & freezer AS/RS and a Mini Load system to handle 25,000 cases daily.

Coca-Cola Bottlers Japan Akashi Mega Distribution Center

Part of the Shinsei Project, this mega DC uses a Unit Load AS/RS, Shuttle Rack, palletizing robots, and RORO stations to handle 80 million beverage cases annually, ensuring stable supply for Osaka and Hyogo.

Deli Group Ninghai Intelligent Logistics Center

China's leading office supplies manufacturer built a 110,000 sq m intelligent logistics center with a multi-system AS/RS complex, AMRs, and picking robots to process 200,000 cases daily and store 130,000 pallets.