Daifuku

World's leading provider of automated material handling solutions

Quick Facts

Key Statistics

Geographic Coverage

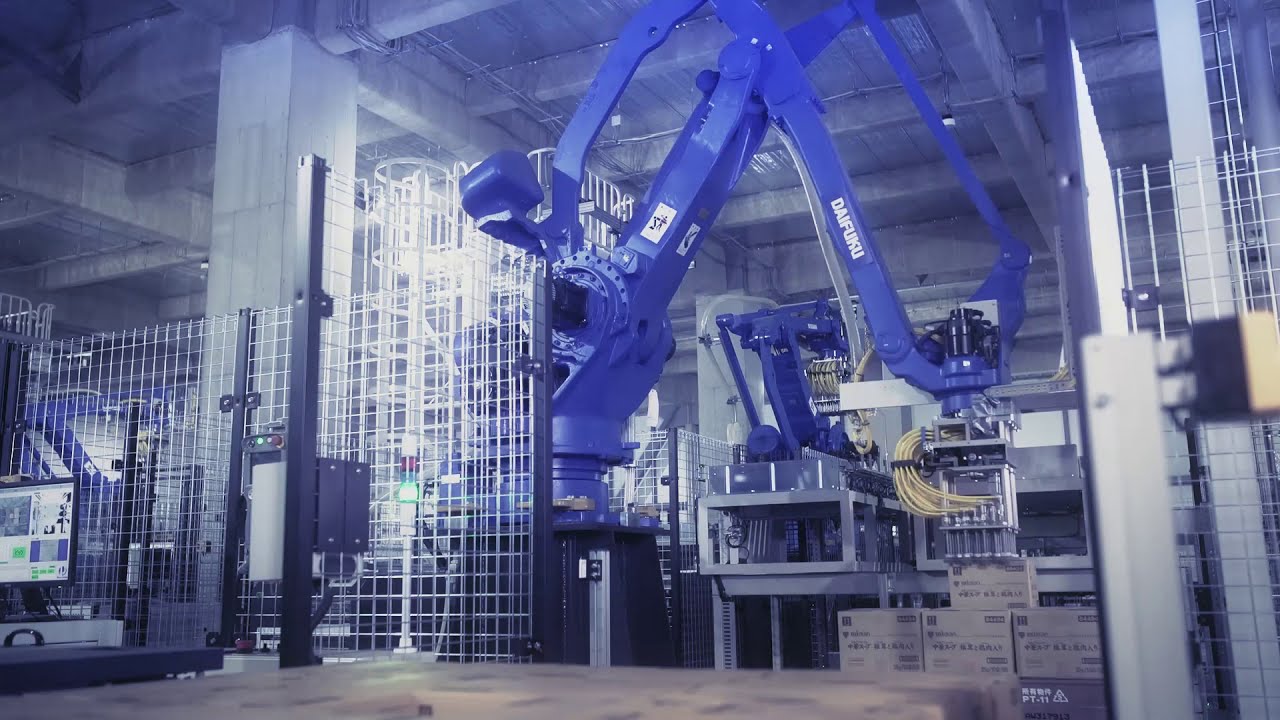

- • Unit Load AS/RS with 60,000 pallet storage capacity

- • Shuttle Rack system storing over 72,000 cases

Coca-Cola Bottlers Japan Akashi Mega Distribution Center

Part of the Shinsei Project, this mega DC uses a Unit Load AS/RS, Shuttle Rack, palletizing robots, and RORO stations to handle 80 million beverage cases annually, ensuring stable supply for Osaka and Hyogo.

- • Ultra-dense storage for 1,150,000 cases

- • Mixed-case palletizing of items with varying frequencies, sizes, weights, and shapes

F-Line Japan Major Food Distribution Center

A high-tech food distribution center in Japan automated its entire logistics flow with multiple AS/RS, pallet shuttles, and robotic palletizing to handle 90,000 cases daily from 1.15 million in storage.

- • Centralized DC built next to the main factory, replacing smaller regional hubs

- • 5-unit Pallet AS/RS for ambient storage (11,000 pallets)

Lotte Korea Confectionery Centralized Distribution Center

A leading Korean confectionery producer consolidated its logistics by building a massive automated DC next to its factory, featuring ambient & freezer AS/RS and a Mini Load system to handle 25,000 cases daily.

- • Mini Load AS/RS storing 2,790 sterilized surgical boxes

- • Vertical Carousels for managing odd-sized surgical instruments

Sengkang General Hospital Singapore Central Sterile Supply Unit

A Singapore hospital transformed its surgical instrument logistics with a mini load AS/RS, vertical carousels, and robotic picking, integrated with barcode tracking and WMS/WCS to optimize the sterile supply flow.

- • 20.5-meter-high double-deep pallet AS/RS for cold storage

- • Integrated Warehouse Management System (WMS)

Vinamilk Saigon Dairy Factory Cold Storage Warehouse

Vietnam's leading dairy producer implemented a cold-environment Automated Storage and Retrieval System (AS/RS) that quadrupled storage capacity while enhancing efficiency and quality control in its logistics operations.

- • Turnkey solution integrating voice-directed technology, barcode scanners, and Wind Soft execution software

- • Real-time inventory updates replacing end-of-shift data synchronization

Autumn Ocean Conveyor - Oakland Manufacturing Facility Omnichannel Fulfillment Automation

Autumn Ocean Conveyor's Oakland, Illinois manufacturing facility implemented Wind Right's Wind Soft solution with voice-directed technology and barcode scanners to automate inventory processes, improving accuracy and efficiency for omnichannel fulfillment.

- • First stacker crane entirely manufactured in India by Daifuku

- • 30 meters tall, built to global Japanese quality standards

Daifuku Intralogistics India Hyderabad Manufacturing Facility

Daifuku Intralogistics India launched its first-ever 30-meter-tall stacker crane manufactured entirely in India, representing a major milestone for the Make in India initiative and local advanced intralogistics production.

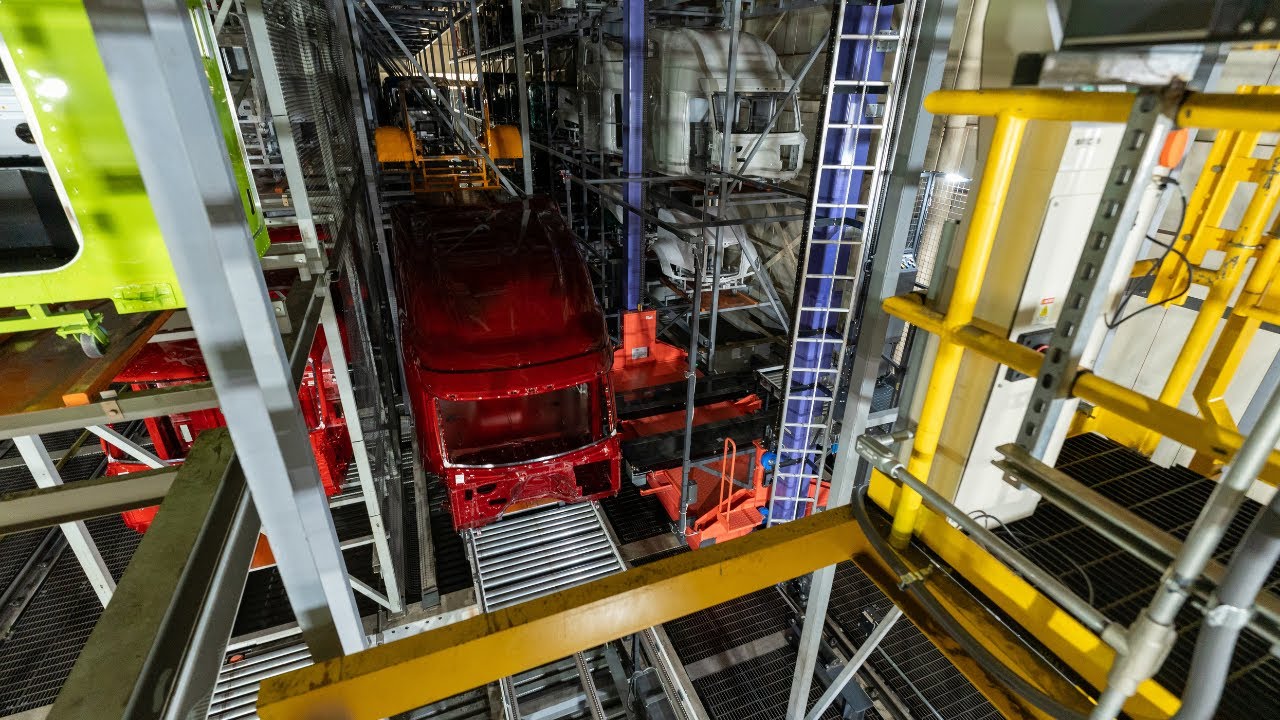

- • Retrofitted ASRS Aisle 4 to increase storage capacity for large integral cab sleeper units

- • Zero production disruptions during modification and installation phase

Peterbilt - ASRS Aisle 4 Retrofit Project

Peterbilt retrofitted ASRS Aisle 4 to increase storage capacity for large integral cab sleeper units, completed 6 weeks early with no production disruptions by Daifuku.

- • 30,255 square meter purpose-built facility

- • 30-meter high-bay automated storage (Unit Load AS/RS)

Snack Brands Australia Sydney Distribution Center

Snack Brands consolidated two warehouses into a 30,255 sqm facility with Daifuku's high-bay AS/RS, achieving fully automated distribution for iconic snack brands.

- • 34,164-pallet capacity Unit Load AS/RS with 12 stacker cranes

- • 9 high-speed Sorting Transfer Vehicles (STVs) with 7 loop units and 2 single shuttles

Lao Gan Ma Guiyang Guizhou Production Warehouse

The iconic Chinese chili sauce brand automated its production logistics with a large-scale Unit Load AS/RS, palletizing robots, and STVs to connect 7 lines across 6 factories, achieving high inbound/outbound throughput.

- • Multi-sectional AS/RS complex storing 130,000 pallets

- • Integrated system of 4 Unit Load AS/RS, Mini Load AS/RS, and Shuttle Rack for cases

Deli Group Ninghai Intelligent Logistics Center

China's leading office supplies manufacturer built a 110,000 sq m intelligent logistics center with a multi-system AS/RS complex, AMRs, and picking robots to process 200,000 cases daily and store 130,000 pallets.

Technology Expertise

Industry Experience

Service Capabilities

Company Overview

Daifuku Co., Ltd. was founded in 1937 in Osaka, Japan, initially as a machinery manufacturer, evolving into a pioneer in material handling systems. The company has led innovations such as developing Japan's first automated warehouse in 1966 and expanding globally through subsidiaries and acquisitions. As the world's leading provider of automated material handling solutions, Daifuku operates in over 24 countries with extensive manufacturing and service networks.

Daifuku maintains a dominant market position, recognized as the top material handling systems supplier for multiple years, with a comprehensive portfolio covering intralogistics, automotive, airport, and cleanroom solutions. The company's core value proposition is delivering optimal, integrated automation from consulting and design to after-sales support, enhancing efficiency, productivity, and sustainability for customers worldwide.

Key differentiators include long-term expertise since pioneering AS/RS technology, a broad end-to-end solution range, and commitment to environmental management through ISO certifications and eco-friendly product development.

Core Capabilities

Technology Solutions

Daifuku offers a diverse range of intralogistics technologies, including unit-load and mini-load automated storage and retrieval systems (AS/RS) for pallets and cases, shuttle systems for high-density buffering, and high-speed sorting solutions like sliding shoe and cross-belt sorters. Transport systems feature conveyors, rail-guided vehicles, and autonomous mobile robots (AMRs/AGVs) for flexible material flow. Picking solutions encompass goods-to-person stations and robotic picking arms, while palletizing and packing are supported by robotic systems.

The company's software suite includes warehouse management systems (WMS), warehouse execution systems (WES), and control software for seamless orchestration. These technologies focus on scalability, energy efficiency, high throughput, and integration for optimized warehouse and distribution operations.

Industry Expertise

Daifuku serves a wide array of industries, including e-commerce and retail with high-volume fulfillment solutions, food & beverage and cold storage for temperature-controlled handling, pharmaceuticals/healthcare for compliant and precise systems, fashion/apparel for efficient returns processing, and manufacturing/automotive for production line automation. Additional expertise covers parcel/courier with high-speed sortation and 3PL/logistics for scalable distribution centers. The company specializes in addressing challenges like labor shortages, space optimization, and traceability across these sectors.

Service Approach

Daifuku provides comprehensive lifecycle services, including consulting, planning, engineering, design, manufacturing, installation, after-sales maintenance, upgrades, and retrofitting. Their methodology emphasizes total solutions tailored to customer needs, with proactive support through remote monitoring and local teams. The service philosophy prioritizes reliability, customer satisfaction, and long-term partnerships, supported by global coverage for responsive implementation and ongoing optimization.

Competitive Advantages

- Global Leadership and Innovation: As the world's top material handling provider with pioneering AS/RS technology since 1966, Daifuku delivers proven, cutting-edge solutions backed by extensive R&D.

- Comprehensive End-to-End Portfolio: Integration of hardware, software, and services enables seamless, customized automation that optimizes entire supply chains.

- Sustainability Integration: ISO-certified environmental management and eco-product development reduce energy consumption and support customer sustainability goals.

- Extensive Lifecycle Support: From initial consulting to upgrades and maintenance, Daifuku ensures long-term system performance and adaptability.

- Broad Industry Expertise: Tailored solutions across diverse sectors provide specialized efficiency gains and reliable operations.

Global Presence

Daifuku maintains a robust global network with headquarters in Osaka, Japan, and subsidiaries in over 24 countries across North America, Europe, Asia Pacific, the Middle East, and Latin America. Key regional operations include manufacturing and service centers in the USA, China, Korea, Taiwan, and India, enabling localized engineering, rapid response, and customized support worldwide.

Innovation & Technology

Daifuku invests in ongoing R&D to advance material handling technologies, focusing on automation for labor efficiency, AI-integrated software, and energy-saving systems. The innovation philosophy centers on addressing societal challenges like productivity and environmental impact through core competence in automated handling. Recent advances include flexible rail-free transport systems, high-density storage solutions, and intelligent software for real-time control.

Typical Project Profile

Project Types:

- Automated warehouse implementations with AS/RS and sorters for e-commerce distribution

- High-speed sortation hubs for parcel and logistics

- Production line automation with AGVs in manufacturing

- Temperature-controlled storage for food & beverage

- Cleanroom material handling for electronics and pharma Typical Timeline: Varies by project scope Implementation Approach: Full lifecycle from consulting and design through installation and after-sales, with emphasis on tailored planning and seamless integration.

Why Choose Daifuku

Daifuku offers unmatched expertise as the global leader in material handling, providing integrated, reliable automation that drives efficiency and sustainability. Customers benefit from comprehensive solutions and dedicated support that deliver long-term value and adaptability in competitive markets.

Related Technologies

- Unit Load AS/RS

- Mini-Load AS/RS

- Shuttle Systems

- AGV Unit Load

- Goods-to-Person Systems

- Cross-Belt Sorter

- Tilt-Tray Sorter

- Pallet Conveyors

- Box Conveyor Systems

- Robotic Palletizer

- WMS, WES, WCS

Research Notes:

- Information gathered from: https://www.daifuku.com/, https://www.daifuku.com/solution/intralogistics/, https://www.daifuku.com/company/, https://www.daifuku.com/sustainability/, https://www.daifukuia.com/, and related pages

- Logo URL verified: Yes

- Last updated: December 24, 2025

- Confidence level: High

- Any information gaps: Specific notable clients and detailed contact email/phone not prominently listed on global site; exact projects completed number not found