Our Curated Projects

24 projects

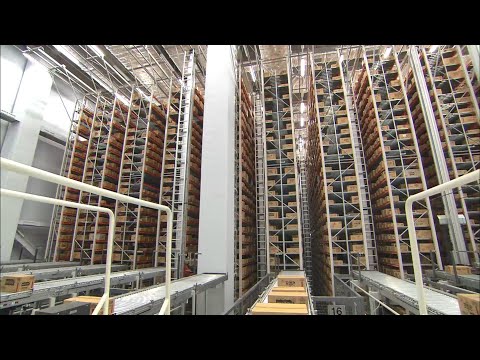

Didactic - Normandy France Healthcare Storage Expansion with Pallet Shuttle

Mecalux designed a customized semi-automatic Pallet Shuttle solution for Didactic (Normandy, France) to address 92% storage capacity utilization, delivering 11,000 pallet capacity with FIFO/LIFO functionality for medical device distribution.

MULTIFLEX Pallet Warehouse: High-Density Frozen Storage

A high-bay automated warehouse system using shuttle operation in storage channels to achieve maximum pallet capacity and high throughput, specifically implemented for frozen goods storage.

LIEKEN High Bay Cold Store for Baked Goods

A high bay cold store for bread and baked goods with a capacity of 6,000 pallets at -24°C, using DAMBACH Storage and Retrieval Machines to achieve 4,296 pallet movements daily.

F-Line Japan Major Food Distribution Center

A high-tech food distribution center in Japan automated its entire logistics flow with multiple AS/RS, pallet shuttles, and robotic palletizing to handle 90,000 cases daily from 1.15 million in storage.

NEXT Doncaster Furniture Distribution Center

NEXT implemented Körber's automated pallet handling solution with RGVs and ASRS across two warehouses for fast furniture and goods movement with 77,000 pallet locations.

BevChain Australia Distribution Center

Australia's first high-density PowerStore system increasing pallet storage capacity by 60% in the same footprint, handling over 30,000 pallet locations across five levels.

Lindab Automated Distribution Center

A 10,600 sqm automated distribution center with high-bay storage handling 250 pallets in/out per hour, featuring 21,500 pallet positions and achieving 50% productivity improvement.

Lotte Korea Confectionery Centralized Distribution Center

A leading Korean confectionery producer consolidated its logistics by building a massive automated DC next to its factory, featuring ambient & freezer AS/RS and a Mini Load system to handle 25,000 cases daily.

Deli Group Ninghai Intelligent Logistics Center

China's leading office supplies manufacturer built a 110,000 sq m intelligent logistics center with a multi-system AS/RS complex, AMRs, and picking robots to process 200,000 cases daily and store 130,000 pallets.

Lao Gan Ma Guiyang Guizhou Production Warehouse

The iconic Chinese chili sauce brand automated its production logistics with a large-scale Unit Load AS/RS, palletizing robots, and STVs to connect 7 lines across 6 factories, achieving high inbound/outbound throughput.

Ospelt Food Sargans Cold Storage Automation

Ospelt Food implemented GEBHARDT's AGV system to optimize pallet transport to cold storage while maintaining the critical cold chain in food production.

SEW-EURODRIVE Bruchsal Electronics Plant

SEW-EURODRIVE built Europe's most modern electronics plant with GEBHARDT's automated pallet storage and multi-level shuttle system for electronic components.

Agile Cold Storage Distribution Center

Third-party cold storage facility tripling pallet capacity to 48,000 in 110,000 sq ft using Swisslog ASRS with SynQ software, serving food manufacturers and global export markets.

Roark - Aerospace Tool & Die Automated Storage System

Roark implemented Bastian Solutions' automated storage and retrieval system for aerospace tools and dies, replacing manual pallet storage with organized ASRS for complex sheet metal fabrication.