Our Curated Projects

15 projects

Didactic - Normandy France Healthcare Storage Expansion with Pallet Shuttle

Mecalux designed a customized semi-automatic Pallet Shuttle solution for Didactic (Normandy, France) to address 92% storage capacity utilization, delivering 11,000 pallet capacity with FIFO/LIFO functionality for medical device distribution.

International 3PL E-commerce Warehouse with RoboShuttle

A 3PL cross-border e-commerce warehouse utilizing Geekplus RoboShuttle, the industry's tallest mobile robot, achieving 500+ units per hour picking efficiency with maximum vertical space utilization.

MULTIFLEX Pallet Warehouse: High-Density Frozen Storage

A high-bay automated warehouse system using shuttle operation in storage channels to achieve maximum pallet capacity and high throughput, specifically implemented for frozen goods storage.

Coca-Cola Bottlers Japan Akashi Mega Distribution Center

Part of the Shinsei Project, this mega DC uses a Unit Load AS/RS, Shuttle Rack, palletizing robots, and RORO stations to handle 80 million beverage cases annually, ensuring stable supply for Osaka and Hyogo.

Landmark Group Kuwait Fulfillment Center

Landmark Group partnered with Addverb to modernize its Kuwait fulfillment center with robotic sorters and carton shuttles, achieving up to 1,000 sorts per hour for enhanced e-commerce operations.

SEW-EURODRIVE Bruchsal Electronics Plant

SEW-EURODRIVE built Europe's most modern electronics plant with GEBHARDT's automated pallet storage and multi-level shuttle system for electronic components.

Lidl Køge Distribution Center

Lidl's distribution center in Køge, Denmark utilizes Vanderlande's automated case picking solution with ADAPTO shuttle-based AS/RS to outperform traditional order fulfillment methods.

Walmart - Next Generation Fulfillment Centers Automation

Walmart partnered with KNAPP to deploy next-generation fulfillment centers featuring Evo 2D Shuttle ASRS, doubling storage capacity and streamlining 12-step processes into 5 steps for omnichannel retail.

HAVI Lisbon Multi-Temperature Logistics Center

Mecalux delivers a multi-temperature logistics center for HAVI in Lisbon, Portugal, featuring two automated warehouses, Pallet Shuttle systems and Easy WMS integration, supporting daily supply to over 150 restaurants.

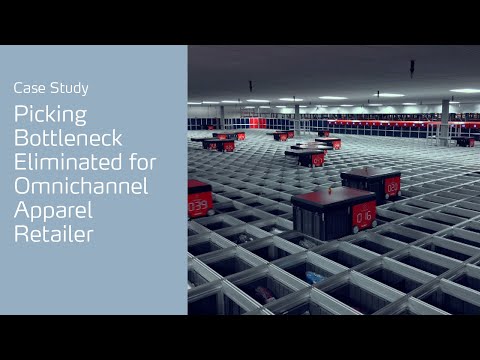

Cutter & Buck Seattle Apparel Fulfillment Center

Cutter & Buck deployed an AutoStore system with 34,000 bins and 54 robots, implemented by Kardex, to streamline apparel fulfillment, reduce storage footprint by 50%, and achieve order turnaround in under 10 minutes.