Projects

101 projects

Our Curated Projects

101 projects

Calzedonia Group Italian Distribution Center Pouch System

Calzedonia Group implemented BEUMER Group's BG Pouch System to expand fulfillment and returns capacity within its existing Italian distribution center, saving floor space with a ceiling-mounted design.

dm-drogerie markt Weilerswist Logistics Center Packaging Line

dm-drogerie markt deployed BEUMER stretch hood® S systems at its central distribution center, automating high-volume pallet packaging with 90 pallets per hour per line and exceptional energy efficiency.

Cruz Azul Hidalgo Tile Mortar Packaging Line

Cruz Azul partnered with BEUMER Group to install a fully automated packaging line for a new tile mortar product, achieving a system throughput of 2,200 bags per hour.

Witt-Gruppe Weiden Distribution Center

Witt-Gruppe deployed BEUMER Group's energy-efficient LS-4000 'green' sorters, the world's first of their kind, achieving over 76% annual energy savings and handling 180,000 items daily.

PUMA Indianapolis Pandemic-Resilient Distribution Center

PUMA's Indianapolis DC, opened on-time in June 2020 amidst the pandemic, provided critical capacity to handle surging e-commerce demand, acting as a 'beacon of hope' for future growth.

CNH Industrial Indianapolis Distribution Center

CNH Industrial partnered with Bastian Solutions to integrate AutoStore, conveyors, sortation cells, and WCS, optimizing their facility for same-day shipping and 24-48 hour fulfillment.

Gleaners Food Bank Indianapolis Back Sack Assembly Line

Gleaners Food Bank collaborated with Bastian Solutions to automate its Back Sack assembly line, expanding the weekend meal program from 3,000 to 10,000 children weekly.

Amway Midwest Regional Service Center, Ada

Amway streamlined its Midwest fulfillment, moving to a new automated facility 50% smaller yet capable of handling over 30,000 cartons daily, achieving faster order fulfillment and reduced costs.

Balluff Inc. Sensor Solutions Automated Warehouse

Balluff Inc. achieved a 177% throughput increase with an AutoStore system implemented by Kardex, featuring an innovative cross-building design installed in just 6 months.

Kesko Helsinki Micro-Fulfillment Center (MFC)

Kesko deployed Finland's first grocery micro-fulfillment center featuring a Dematic AutoStore system in a chilled environment, doubling daily volumes and enabling 6-hour delivery.

Cutter & Buck Seattle Apparel Fulfillment Center

Cutter & Buck deployed an AutoStore system with 34,000 bins and 54 robots, implemented by Kardex, to streamline apparel fulfillment, reduce storage footprint by 50%, and achieve order turnaround in under 10 minutes.

Alza Prague High-Throughput Fulfillment Center

Alza, the largest Czech/Slovak online retailer, deployed a 300,000-bin, 580-robot AutoStore system integrated by Element Logic, achieving 75% faster picking and handling up to 260,000 daily orders.

Addverb 3PL Omnichannel Fulfillment Center

Addverb transformed a 330,000 sq. ft. 3PL facility with integrated fixed and flexible automation, enabling seamless B2B and B2C operations and a dispatch of 100,000 pieces daily.

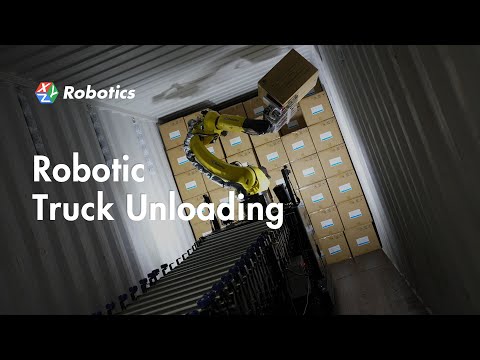

XYZ Robotics - Japanese 3PL Warehouse Robotic Truck & Container Unloading Project

XYZ Robotics deploys RockyOne Mobile Manipulation Robot to automate truck and container unloading for a Japanese 3PL warehouse, handling 15-kg cartons in 40-ft containers within 2 hours.