Mecalux Shuttle System: Automated AS/RS for Boxes and Small Parts

⚡Quick Facts

Technology Performance Metrics

⭐Key Features

✨Benefits

🎯Applications

📝Detailed Information

Technology Overview

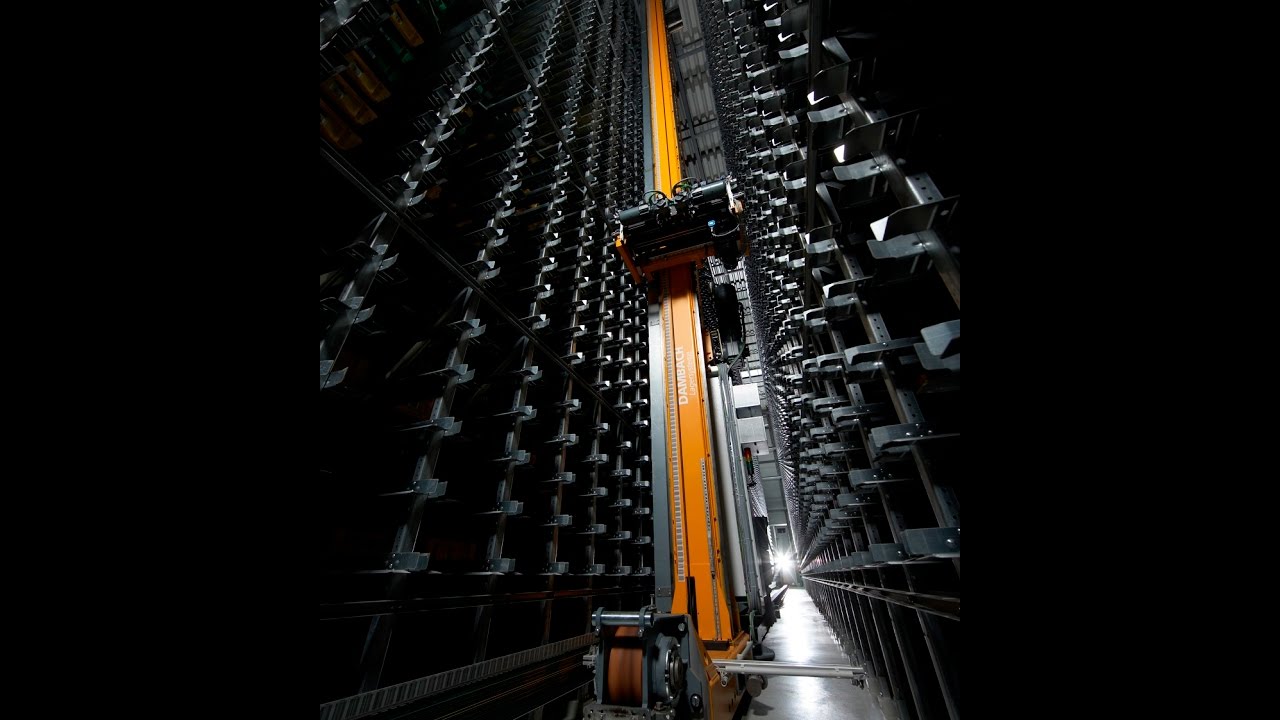

The Mecalux Shuttle System is a high-performance automated storage and retrieval system (AS/RS) specifically engineered for handling boxes, plastic totes, bins, and small parts. It is designed to address core challenges in modern logistics: accelerating order fulfillment, maximizing storage density, and ensuring uninterrupted operation. The system automates the entire storage and retrieval process, creating a seamless flow of goods from high-density storage directly to pick stations. Utilizing a fleet of high-speed shuttles, vertical lifts, and conveyors, it forms a fully automated backbone for warehouses. A key aspect is its integration with Mecalux's Easy WMS, which acts as the central nervous system, and its compatibility with AI-powered robotic picking solutions. This makes it a comprehensive automation platform suitable for a wide range of industries seeking to boost productivity, especially those managing a high volume of small items in space-constrained facilities.

How It Works

Core Principles

The system operates on the principle of automated, high-density goods-to-person fulfillment. Autonomous shuttles operating on multiple levels within a rack structure retrieve storage containers (totes/boxes) and deliver them via a network of lifts and conveyors directly to ergonomic pick stations, where operators or robots complete the order.

Key Features & Capabilities

High-Speed Shuttle Fleet is the performance engine. Shuttles moving at 4 m/s with dual-box carrying capacity enable high transaction rates, ensuring rapid response to order demands and supporting high throughput picking stations.

Integrated Multi-Level Vertical Handling is a key density enabler. The combination of shuttles and lifts allows the system to utilize full vertical space. The redesigned functionality for shuttles to change levels using lifts adds further flexibility in 3D space utilization.

Seamless Software and Robotics Integration creates a cohesive ecosystem. The system is centrally managed by Easy WMS and can be integrated with Mecalux's AI-powered picking robots, allowing for fully automated or hybrid robotic/human picking cells within the same flow.

Advantages & Benefits

The primary advantage is a dramatic increase in order picking speed and accuracy. By automating retrieval and delivering items directly to pickers, it eliminates travel and search time, significantly boosting picks per hour while reducing errors.

It delivers exceptional space optimization and storage density. By utilizing both vertical height and horizontal depth with high-density racking, the system can store a much larger volume of goods in the same footprint, deferring facility expansion costs.

The system provides operational resilience and scalability. Its 24/7 capability and modular design mean it can support continuous operations and be expanded incrementally by adding more shuttles, lifts, or storage modules as business needs grow.

Implementation Considerations

The system is optimized for small to medium-sized unit loads (boxes/totes up to 50 kg). Operations handling larger or heavier items would need to evaluate alternative solutions.

Realizing the full potential requires deep integration of hardware and software. The success of the high-throughput operation depends on the flawless interplay between the shuttles, lifts, conveyors, and the Easy WMS, necessitating expert implementation.

While offering easy maintenance, the system's complexity implies the need for technical staff or service contracts to maintain high availability of the shuttle fleet, lifts, and control systems.

Use Cases & Applications

Ideal For

This system is ideal for e-commerce fulfillment centers, pharmaceutical distributors, electronics parts warehouses, and any operation that handles a high SKU count of small items and requires fast, accurate order picking to meet tight service-level agreements.

Performance Metrics

Key performance indicators from the content include:

- Shuttle Speed: Up to 4 meters per second.

- Throughput: High-performance pick stations can achieve up to 1,000 picks per hour.

- Load Capacity: Each shuttle can carry two boxes, maximum 50 kg each.

- Operational Uptime: Capable of continuous 24/7 operation.

Conclusion

The Mecalux Shuttle System represents a mature and highly capable automation solution for the efficient handling of small-item inventory. It excels at transforming storage and picking into a fast, dense, and software-driven process. For businesses grappling with space constraints, labor-intensive picking, and the need for faster order cycles, this system offers a proven path to significant operational improvement. Its strength lies not just in the hardware but in its holistic design that integrates storage, conveyance, software, and optional robotics. Successful implementation requires careful planning and partnership but can yield a transformative boost in productivity, accuracy, and scalability, providing a robust foundation for growth in demanding sectors like e-commerce and omni-channel retail.

📦Related Projects

Didactic - Normandy France Healthcare Storage Expansion with Pallet Shuttle

Mecalux designed a customized semi-automatic Pallet Shuttle solution for Didactic (Normandy, France) to address 92% storage capacity utilization, delivering 11,000 pallet capacity with FIFO/LIFO functionality for medical device distribution.

HAVI Lisbon Multi-Temperature Logistics Center

Mecalux delivers a multi-temperature logistics center for HAVI in Lisbon, Portugal, featuring two automated warehouses, Pallet Shuttle systems and Easy WMS integration, supporting daily supply to over 150 restaurants.

Michelin Vitoria Tire Plant Automated Warehouse

Mecalux delivers a 27-meter high automated clad rack warehouse for Michelin's Vitoria tire plant in Spain, supporting three production lines and a planned fourth with 4,600 container capacity and 120 containers per hour throughput.