Production Logistics Strategy

Production logistics orchestrates the seamless flow of materials, components, and finished goods within manufacturing operations. From just-in-time delivery to line-side replenishment, master the strategies that keep production lines running efficiently while minimizing inventory and maximizing throughput.

🏭 Production Logistics Strategy Mind Map

- ▸Just-in-Time (JIT)Minimal inventory flow

- ▸Just-in-Sequence (JIS)Sequenced delivery

- ▸Kanban SystemsVisual pull signals

- ▸Milk RunScheduled routes

- ▸Supermarket SystemsLine-side storage

- ▸Manufacturing WMSSpecialized warehouse systems

- ▸AGVs & AMRsAutonomous transport

- ▸AS/RS SystemsAutomated storage

- ▸MES IntegrationExecution systems

- ▸IoT & SensorsReal-time tracking

- ▸Inbound ReceiptMaterial receiving

- ▸Kitting & Sub-AssemblyMaterial preparation

- ▸Line-Side ReplenishmentProduction delivery

- ▸WIP ManagementIn-process tracking

- ▸Finished GoodsOutput handling

- ▸Waste EliminationSeven wastes (Muda)

- ▸Value Stream MappingFlow visualization

- ▸5S WorkplaceOrganization system

- ▸Continuous FlowMinimize batching

- ▸KaizenContinuous improvement

- ▸Inventory Reduction50-80% with JIT

- ▸Space Optimization60-80% reduction

- ▸Labor Productivity50-70% improvement

- ▸Transport Costs30-50% savings (milk run)

- ▸Supply DisruptionsMaterial shortages

- ▸Production VariabilityDemand fluctuations

- ▸Space ConstraintsLimited floor space

- ▸Quality IssuesDefective materials

- ▸Material AvailabilityUninterrupted flow

- ▸Inventory MinimizationReduce working capital

- ▸Quality AssuranceDefect-free delivery

- ▸Cost EfficiencyMinimize waste

📋 What is Production Logistics?

Production logistics encompasses all activities related to planning, implementing, and controlling the flow of materials, components, and finished goods within and around manufacturing facilities. It bridges the gap between inbound supply chain operations and outbound distribution, ensuring that production lines have the right materials, in the right quantities, at the right time, and in the right location.

Unlike traditional warehousing that focuses on storage and order fulfillment, production logistics emphasizes continuous material flow, minimal inventory, and synchronized operations. The goal is to eliminate waste, reduce lead times, and create a seamless connection between suppliers, internal operations, and customers.

Core Objectives:

- Material Availability: Ensure uninterrupted production flow

- Inventory Minimization: Reduce working capital tied up in materials

- Space Optimization: Maximize productive manufacturing space

- Quality Assurance: Deliver defect-free materials to production

- Cost Efficiency: Minimize handling, storage, and obsolescence costs

- Flexibility: Adapt quickly to production schedule changes

🔄 Production Logistics Models

1. Just-in-Time (JIT) Logistics

Materials arrive precisely when needed for production, eliminating storage and reducing inventory.

Core Principles:

- Pull-based system driven by actual demand

- Minimal buffer inventory

- Frequent, small deliveries

- Close supplier partnerships

- Synchronized production schedules

- Continuous flow manufacturing

Benefits:

- 50-80% reduction in inventory levels

- Reduced warehouse space requirements

- Lower carrying costs

- Improved cash flow

- Reduced obsolescence risk

- Enhanced quality focus

Challenges:

- Supply chain vulnerability

- Requires reliable suppliers

- Transportation cost increases

- Limited flexibility for disruptions

- Extensive coordination needed

Best For: High-volume, stable production with reliable suppliers (automotive, electronics assembly)

2. Just-in-Sequence (JIS) Logistics

Advanced JIT where materials arrive in the exact sequence needed for production.

Key Features:

- Sequence-specific delivery

- Direct line-side delivery

- No sorting or staging required

- Synchronized with production schedule

- Supplier visibility into production sequence

Applications:

- Automotive final assembly (seats, dashboards)

- Custom product manufacturing

- Mixed-model production lines

- High-variety, low-volume production

Requirements:

- Real-time production visibility

- Advanced planning systems

- Supplier proximity (typically <2 hours)

- Robust communication infrastructure

- Sequencing facilities (often supplier-operated)

Impact:

- Eliminates line-side inventory

- Reduces handling and errors

- Enables mass customization

- Minimizes production floor space

3. Kanban Systems

Visual signal-based pull system for material replenishment.

Types of Kanban:

Single-Card Kanban:

- Production kanban only

- Signals when to produce

- Simple implementation

- Suitable for stable demand

Two-Card Kanban:

- Production and withdrawal kanbans

- More flexible material flow

- Better for complex operations

- Separates production from movement

Electronic Kanban (e-Kanban):

- Digital signals replace physical cards

- Real-time visibility

- Automated replenishment triggers

- Integration with ERP/MES systems

Implementation:

- Define container sizes and quantities

- Establish reorder points

- Create visual signals (cards, lights, digital)

- Train operators on system

- Continuously optimize levels

Benefits:

- Self-regulating system

- Reduced inventory (30-50%)

- Improved material flow

- Enhanced visibility

- Empowered workforce

4. Milk Run Logistics

Scheduled, fixed-route material delivery system inspired by traditional milk delivery.

Internal Milk Runs:

- Regular routes within facility

- Timed deliveries to production lines

- Standardized containers

- Predictable material flow

- Reduced forklift traffic

External Milk Runs:

- Consolidated supplier pickups

- Single vehicle visits multiple suppliers

- Reduced transportation costs

- Improved delivery frequency

- Better supplier collaboration

Design Considerations:

- Route optimization

- Delivery frequency

- Container standardization

- Vehicle selection (AGV, tugger trains)

- Scheduling synchronization

Advantages:

- 30-50% reduction in transportation costs

- Increased delivery frequency

- Reduced packaging waste

- Improved space utilization

- Predictable material availability

5. Supermarket Systems

Strategically located material storage points near production lines.

Concept:

- Decentralized storage locations

- Self-service for production operators

- Visual inventory management

- Replenishment based on consumption

- Organized by product family or line

Design Elements:

- Flow racks for FIFO rotation

- Clear labeling and organization

- Ergonomic access

- Visual min/max indicators

- Integrated with kanban signals

Benefits:

- Reduced line-side clutter

- Improved material availability

- Faster material access

- Better inventory visibility

- Reduced material handling

Sizing:

- Typically 2-4 hours of production

- Balance between availability and space

- Consider replenishment frequency

- Account for variability

🤖 Production Logistics Technologies

Warehouse Management Systems (WMS) for Manufacturing

Specialized WMS capabilities for production environments.

Manufacturing-Specific Features:

- Kitting and sub-assembly management

- Work-in-process (WIP) tracking

- Line-side inventory management

- Kanban integration

- Production schedule synchronization

- Quality hold and quarantine

- Lot and serial number tracking

Integration Points:

- ERP (Enterprise Resource Planning)

- MES (Manufacturing Execution System)

- PLM (Product Lifecycle Management)

- Quality management systems

- Supplier portals

Leading Solutions:

- SAP Extended Warehouse Management

- Oracle WMS Cloud

- Manhattan Associates

- Blue Yonder (JDA)

- Infor WMS

Automated Guided Vehicles (AGVs) and AMRs

Autonomous material transport within manufacturing facilities.

AGV Types:

Tugger AGVs:

- Pull multiple carts in train configuration

- Ideal for milk run routes

- Payload: 1,000-5,000 kg

- Flexible route programming

Unit Load AGVs:

- Transport pallets or containers

- Point-to-point delivery

- Payload: 500-2,000 kg

- Integration with conveyors

Forklift AGVs:

- Automated pallet handling

- Rack storage and retrieval

- Payload: 1,000-2,500 kg

- Replaces manual forklifts

AMR Advantages:

- Dynamic path planning

- No fixed infrastructure

- Easy reconfiguration

- Collaborative operation

- Faster deployment

ROI Considerations:

- Labor cost savings: 50-70%

- Improved safety

- 24/7 operation capability

- Consistency and reliability

- Typical payback: 18-36 months

Automated Storage and Retrieval (AS/RS)

High-density storage for production materials and components.

Mini-Load AS/RS:

- Small parts and components

- Tote or tray storage

- High-speed retrieval

- Integration with kitting stations

- Throughput: 100-300 totes/hour

Vertical Lift Modules (VLMs):

- Compact footprint

- Ergonomic delivery height

- Ideal for slow-moving parts

- Space savings: 75-85%

- Inventory accuracy: 99.9%+

Horizontal Carousels:

- Rotating shelving system

- Goods-to-person delivery

- Batch picking capability

- Lower cost than VLMs

- Throughput: 300-600 lines/hour

Benefits for Production:

- Reduced floor space (60-80%)

- Improved inventory accuracy

- Faster material access

- Better security and control

- Reduced labor requirements

Conveyor and Sortation Systems

Automated material flow between operations.

Conveyor Types:

Roller Conveyors:

- Gravity or powered

- Pallets and containers

- Flexible layouts

- Low maintenance

Belt Conveyors:

- Continuous flow

- Various load types

- Incline capability

- Gentle handling

Overhead Conveyors:

- Saves floor space

- Long-distance transport

- Work-in-process storage

- Paint line applications

Sortation Systems:

- Divert materials to production lines

- Sequence-based routing

- High-speed operation

- Integration with MES

Manufacturing Execution Systems (MES)

Real-time production management and material tracking.

Core Functions:

- Production scheduling and dispatch

- Material consumption tracking

- Work-in-process visibility

- Quality data collection

- Performance monitoring (OEE)

- Genealogy and traceability

Material Management:

- Bill of material (BOM) verification

- Component allocation

- Shortage alerts

- Backflush consumption

- Scrap and rework tracking

Integration Benefits:

- Real-time material requirements

- Automated replenishment triggers

- Improved material traceability

- Reduced material errors

- Enhanced compliance

IoT and Smart Sensors

Real-time visibility and monitoring of materials and equipment.

Applications:

- Inventory level monitoring

- Container location tracking

- Equipment status monitoring

- Environmental conditions

- Predictive maintenance

Technologies:

- RFID tags and readers

- Bluetooth beacons

- Vision systems

- Weight sensors

- Light curtains

Benefits:

- Real-time visibility

- Automated data collection

- Reduced manual counting

- Proactive replenishment

- Improved accuracy

🏭 Production Logistics Processes

Inbound Material Receipt

Process Flow:

- Advance Shipping Notice (ASN): Electronic notification from supplier

- Dock Scheduling: Time-slot assignment for deliveries

- Receipt Verification: Quantity and quality checks

- Put-away: Direct to line-side or staging area

- System Update: Inventory and production visibility

Best Practices:

- Cross-docking when possible

- Quality inspection at receipt

- Supplier certification programs

- Barcode/RFID scanning

- Exception management processes

Kitting and Sub-Assembly

Preparing material sets for production orders.

Kitting Strategies:

Pre-Kitting:

- Materials assembled before production

- Reduces line-side complexity

- Requires accurate forecasting

- Risk of obsolescence

Just-in-Time Kitting:

- Kitted based on actual orders

- Reduced inventory risk

- Requires fast kitting process

- Better for high-variety production

Line-Side Kitting:

- Operators assemble own kits

- Eliminates kitting labor

- Requires organized supermarkets

- Suitable for simple assemblies

Kitting Technologies:

- Pick-to-light systems

- Voice-directed picking

- Automated kitting cells

- Vision-guided assembly

- Collaborative robots

Line-Side Replenishment

Delivering materials to production points.

Replenishment Methods:

Scheduled Replenishment:

- Fixed time intervals

- Predictable material flow

- Suitable for stable consumption

- Milk run compatible

Consumption-Based:

- Triggered by actual usage

- Kanban signals

- Minimizes inventory

- Requires responsive system

Min/Max Replenishment:

- Reorder when minimum reached

- Replenish to maximum level

- Buffer for variability

- Simple to implement

Delivery Methods:

- Manual tugger trains

- AGV/AMR delivery

- Conveyor systems

- Overhead cranes

- Gravity feed systems

Work-in-Process (WIP) Management

Tracking and controlling materials in production.

WIP Challenges:

- Visibility gaps

- Inventory accuracy

- Production bottlenecks

- Quality issues

- Space constraints

Management Strategies:

- FIFO lanes and buffers

- Visual management boards

- Electronic tracking (RFID, barcode)

- Supermarket pull systems

- Continuous flow manufacturing

Metrics:

- WIP inventory levels

- WIP turns

- Cycle time

- Lead time

- Queue time

Finished Goods Handling

Moving completed products from production to distribution.

Process Steps:

- Production Completion: Final quality check

- Packaging: Protective and shipping packaging

- Labeling: Product and shipping labels

- Staging: Organize for shipment

- Loading: Transfer to distribution

Automation Opportunities:

- Automated packaging lines

- Robotic palletizing

- Automated labeling

- Conveyor to shipping

- AS/RS for finished goods

💰 Economic Impact and Optimization

Cost Components

Direct Costs:

- Material handling labor: 30-40% of total

- Equipment and automation: 25-35%

- Inventory carrying costs: 15-25%

- Transportation (internal): 10-15%

- Packaging and containers: 5-10%

Hidden Costs:

- Production downtime due to material shortages

- Excess inventory obsolescence

- Quality issues from poor handling

- Space opportunity costs

- Expedited freight charges

Inventory Optimization

Inventory Types:

Raw Materials:

- Supplier lead time coverage

- Safety stock for variability

- Economic order quantities

- Consignment inventory

Work-in-Process:

- Minimize through flow manufacturing

- Buffer only at constraints

- Visual management

- Continuous improvement

Finished Goods:

- Make-to-order vs. make-to-stock

- Postponement strategies

- Safety stock optimization

- Demand-driven replenishment

Optimization Techniques:

- ABC analysis for prioritization

- Statistical safety stock calculation

- Multi-echelon inventory optimization

- Vendor-managed inventory (VMI)

- Consignment programs

Space Utilization

Strategies:

- Vertical storage solutions

- Compact mobile racking

- Overhead conveyors

- Mezzanine levels

- Off-site storage for slow-movers

Metrics:

- Inventory per square foot

- Cubic utilization

- Production space ratio

- Material staging area size

- Aisle space percentage

Labor Productivity

Improvement Levers:

- Automation and mechanization

- Ergonomic workstation design

- Standardized work procedures

- Visual management

- Continuous training

Metrics:

- Units handled per labor hour

- Travel distance per shift

- Picking accuracy

- Replenishment cycle time

- Value-added vs. non-value-added time

⚠️ Challenges and Solutions

Supply Chain Disruptions

Challenge: Material shortages halting production

Solutions:

- Dual sourcing strategies

- Safety stock for critical items

- Supplier relationship management

- Real-time visibility and alerts

- Flexible production scheduling

- Alternative material qualification

Production Variability

Challenge: Unpredictable material consumption rates

Solutions:

- Dynamic kanban sizing

- Flexible replenishment schedules

- Buffer supermarkets

- Real-time consumption tracking

- Collaborative planning with production

Space Constraints

Challenge: Limited floor space for materials

Solutions:

- Vertical storage systems

- Off-site kitting and sequencing

- Supplier-managed inventory

- Frequent deliveries (reduce batch sizes)

- Lean layout redesign

Quality Issues

Challenge: Defective materials disrupting production

Solutions:

- Supplier quality agreements

- Incoming inspection protocols

- Statistical process control

- Root cause analysis

- Supplier development programs

- Certified supplier programs

System Integration

Challenge: Disconnected systems causing information gaps

Solutions:

- Integrated ERP/MES/WMS platforms

- API-based integration

- Real-time data synchronization

- Master data management

- Single source of truth

🌱 Lean Manufacturing Integration

Waste Elimination (Muda)

Seven Wastes in Production Logistics:

- Transportation: Excessive material movement

- Inventory: Excess raw materials and WIP

- Motion: Unnecessary operator movement

- Waiting: Production delays due to materials

- Overproduction: Making more than needed

- Over-processing: Unnecessary handling steps

- Defects: Quality issues requiring rework

Elimination Strategies:

- Value stream mapping

- 5S workplace organization

- Continuous flow manufacturing

- Pull systems (kanban)

- Standardized work

- Kaizen (continuous improvement)

Value Stream Mapping

Visualizing material and information flow to identify waste.

Process:

- Select product family

- Map current state

- Identify waste and constraints

- Design future state

- Create implementation plan

- Execute and measure

Key Metrics:

- Lead time

- Process time

- Value-added time

- Inventory levels

- Change-over time

- First-pass yield

5S Implementation

Workplace organization for efficiency and safety.

5S Principles:

- Sort (Seiri): Remove unnecessary items

- Set in Order (Seiton): Organize for efficiency

- Shine (Seiso): Clean and inspect

- Standardize (Seiketsu): Create standards

- Sustain (Shitsuke): Maintain discipline

Benefits:

- Reduced search time (50-70%)

- Improved safety

- Better quality

- Enhanced morale

- Foundation for continuous improvement

🚀 Future Trends and Innovations

Industry 4.0 and Smart Manufacturing

Digital Twin Technology:

- Virtual replica of physical operations

- Simulation and optimization

- Predictive analytics

- Real-time monitoring

- Scenario planning

Artificial Intelligence:

- Demand forecasting

- Dynamic scheduling

- Predictive maintenance

- Quality prediction

- Autonomous decision-making

Machine Learning:

- Pattern recognition

- Anomaly detection

- Process optimization

- Adaptive systems

- Continuous learning

Advanced Robotics

Collaborative Robots (Cobots):

- Work alongside humans

- Flexible deployment

- Easy programming

- Material handling and kitting

- Quality inspection

Autonomous Mobile Robots (AMRs):

- Dynamic navigation

- Fleet management

- Swarm intelligence

- Human-robot collaboration

- Scalable deployment

Robotic Process Automation (RPA):

- Automated data entry

- System integration

- Exception handling

- Report generation

- Compliance documentation

Augmented Reality (AR)

Applications:

- Pick-by-vision systems

- Assembly instructions

- Maintenance guidance

- Training and onboarding

- Quality inspection

Benefits:

- Hands-free operation

- Reduced errors (30-50%)

- Faster training

- Improved productivity

- Enhanced safety

Blockchain for Traceability

Use Cases:

- Material provenance tracking

- Quality certification

- Supplier verification

- Compliance documentation

- Counterfeit prevention

Benefits:

- Immutable records

- Enhanced transparency

- Faster recalls

- Improved trust

- Regulatory compliance

Sustainable Production Logistics

Green Initiatives:

- Electric AGVs and forklifts

- Renewable energy powered facilities

- Reusable packaging systems

- Waste reduction programs

- Carbon footprint tracking

Circular Economy:

- Closed-loop material flows

- Remanufacturing integration

- Waste-to-resource conversion

- Sustainable sourcing

- Product lifecycle management

✅ Best Practices for Production Logistics Excellence

Strategic Planning

- Align with Production Strategy: Match logistics approach to manufacturing model

- Supplier Collaboration: Develop strategic partnerships

- Technology Roadmap: Plan phased automation implementation

- Continuous Improvement Culture: Empower employees to identify waste

- Performance Metrics: Track and optimize key KPIs

Operational Excellence

- Standardized Processes: Document and train on standard work

- Visual Management: Make problems visible immediately

- Quality at Source: Prevent defects from reaching production

- Flexible Systems: Design for variability and change

- Cross-Training: Develop multi-skilled workforce

Technology Implementation

- Start with Process: Optimize before automating

- Phased Approach: Pilot, learn, scale

- Integration Focus: Ensure seamless data flow

- User-Centric Design: Involve operators in selection

- Change Management: Support workforce through transition

Supplier Management

- Supplier Development: Invest in capability building

- Performance Scorecards: Track quality, delivery, cost

- Collaborative Planning: Share forecasts and schedules

- Certification Programs: Reduce incoming inspection

- Risk Management: Diversify and monitor supply base

Continuous Improvement

- Kaizen Events: Regular improvement workshops

- Root Cause Analysis: Solve problems permanently

- Benchmarking: Learn from best practices

- Innovation: Encourage experimentation

- Measurement: Track progress and celebrate wins

🎯 Conclusion

Production logistics is the critical link that transforms raw materials into finished products efficiently and cost-effectively. Success requires a holistic approach that integrates lean principles, advanced technologies, and collaborative partnerships to create seamless material flow.

The future of production logistics lies in smart, connected, and autonomous systems that adapt in real-time to changing conditions. Organizations that embrace digital transformation while maintaining focus on fundamental lean principles will achieve competitive advantages in quality, cost, and delivery performance.

Key Success Factors:

- Alignment between logistics and production strategies

- Investment in appropriate automation and technology

- Strong supplier partnerships and collaboration

- Continuous improvement culture and employee engagement

- Real-time visibility and data-driven decision making

- Flexibility to adapt to changing market demands

By mastering production logistics, manufacturers can achieve the holy grail of operations: the right material, in the right place, at the right time, every time—enabling world-class manufacturing performance.

🔧Related Technologies (6)

Mobile Picking Robot (MPR): Smart Logistics Automation

byHyundai

KUKA AMRs: Autonomous Mobile Robots for Flexible Production and Logistics

byKUKA

Collaborative AMR System with Vision-Guided Robotic Arm for Part Transfer

byOthers

AGV Systems: Custom Turnkey Tugger Solutions

byROBOS

Robotic Palletizing Systems: Comprehensive Guide for Manufacturing

by Columbia/Okura LLC

Monorail Systems for High-Volume Commercial Laundry

byOthers

📚Related Strategy Topics

About This Strategy

📁Related Projects(6)

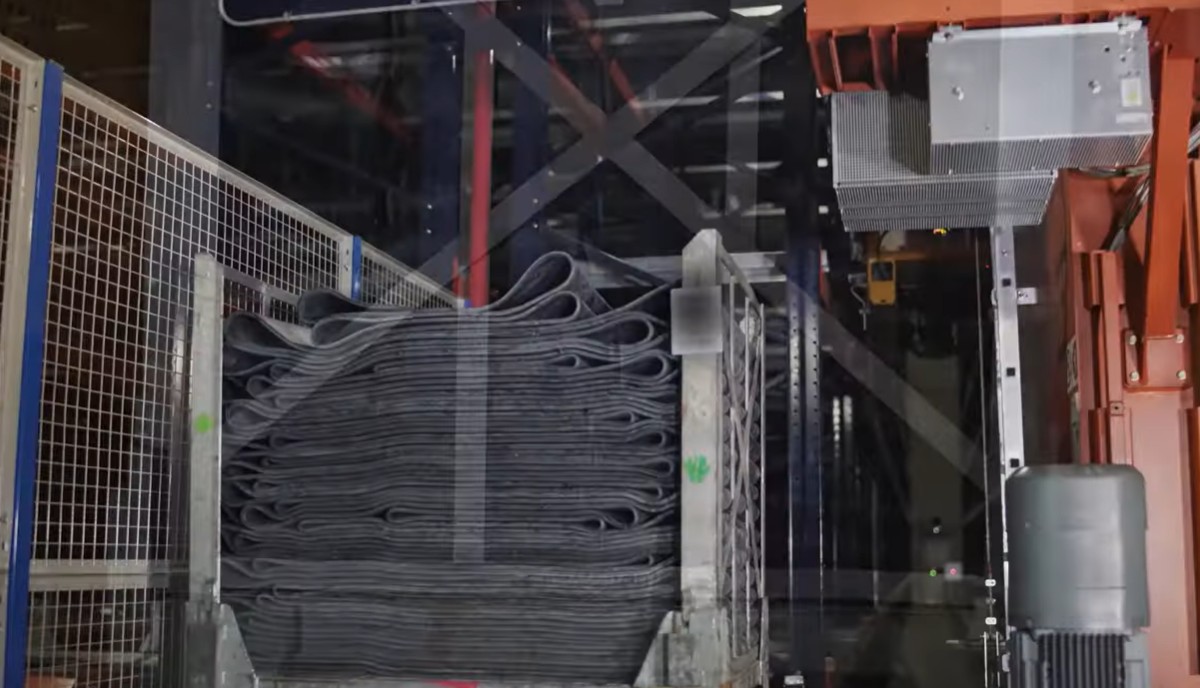

Michelin Vitoria Tire Plant Automated Warehouse

Mecalux

Hirschmann Automotive Rankweil Production Logistics

Servus Intralogistics

V-ZUG Kühltechnik Sulgen Refrigerator Factory

GEBHARDT Intralogistics Group

SMC Corporation Indiana Distribution Center

Bastian Solutions

Autumn Ocean Conveyor - Oakland Manufacturing Facility Omnichannel Fulfillment Automation

Daifuku

Lindab Automated Distribution Center

Swisslog