Robotic Palletizing Systems: Comprehensive Guide for Manufacturing

⚡Quick Facts

Technology Performance Metrics

⭐Key Features

✨Benefits

🎯Applications

📝Detailed Information

Technology Overview

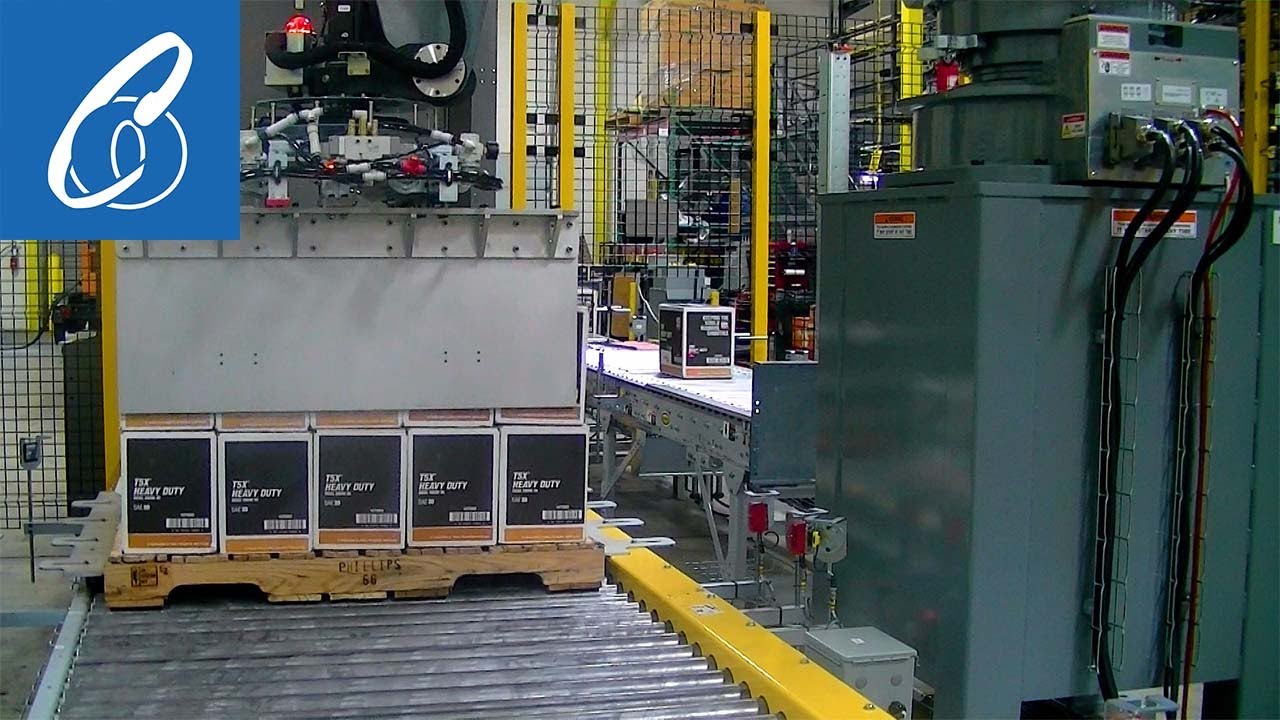

Robotic palletizing systems represent a highly flexible and efficient method for automating the end-of-line process in manufacturing and processing facilities. These systems replace manual or fixed automation palletizers with programmable robotic arms, offering significant advantages in adaptability, footprint optimization, and handling diverse products. The core principle is to use an articulated robot arm equipped with a specialized end-effector to pick products from an infeed conveyor and place them onto a pallet in a predefined pattern. This technology is particularly valuable in environments with multiple product lines, frequent changeovers, or space limitations, as it can be precisely engineered to meet specific plant constraints and throughput requirements.

How It Works

Core Principles

The system operates on the principle of using a multi-axis articulated robot to automate the stacking of products onto a pallet. The robot's movements and picking patterns are programmed based on the product dimensions, pallet size, and desired load stability. Flexibility is achieved through software-programmable patterns and interchangeable or multi-functional end effectors, allowing the same system to handle different products without major mechanical changes.

Key Features & Capabilities

Multi-Line Palletizing: A single articulated robot can service up to four different packaging lines simultaneously, picking products from each and building loads on dedicated pallet stations. This dramatically reduces the floor space and equipment needed compared to dedicated palletizers for each line.

Adaptable End Effectors: The end effector (gripping tool) is highly customizable. It can be designed as a common tool to handle multiple product types (e.g., cases and bags), or tools can be changed. This versatility allows a single robotic system to palletize a wide range of packages, making it a flexible, long-term investment.

Flexible Layout & Integration: The robotic cell can be configured in endless layout possibilities to fit within existing plant constraints. It seamlessly integrates with a wide array of peripheral equipment—conveyors, pallet dispensers, sheet dispensers, labelers, checkweighers, and stretch wrappers—to create a complete, automated end-of-line solution.

Product Orientation and Handling: To optimize robot cycle time and meet palletizing rates, systems include features for product orientation. This can be achieved through "soft turning" using variable speed split conveyors or mechanical turning devices, ensuring products are presented correctly for pickup.

Advantages & Benefits

The primary advantage is space and cost optimization. By designing the system around specific plant constraints, it utilizes the least amount of valuable floor space. A single robot handling multiple lines further reduces the footprint and minimizes investment in duplicate peripheral equipment. Operational flexibility is another key benefit; the system can adapt to different products, patterns, and changeovers through software, protecting the investment against future changes. Finally, it improves efficiency through faster, consistent cycle times compared to manual palletizing and reduces physical strain on workers.

Implementation Considerations

Implementing a robotic palletizing system requires a thorough analysis of multiple factors: production throughput, available space, package types and speeds, frequency of product changeovers, pattern complexity, and load-building requirements. The total cost of ownership (TCO) must be evaluated, encompassing not just the initial purchase but also freight, installation, maintenance, spare parts, operational costs, and training. Careful planning of the entire work cell configuration is crucial, as the integration and performance of each peripheral piece (conveyors, dispensers) directly impact the system's overall cycle time and effectiveness.

Use Cases & Applications

Ideal For

Robotic palletizing is ideal for manufacturing and processing facilities across food & beverage, consumer goods, chemicals, and building materials that have multiple production lines, diverse product SKUs, frequent changeovers, or are constrained by available floor space.

Conclusion

Robotic palletizing systems offer a powerful, flexible solution for automating a critical and labor-intensive stage in manufacturing. The technology's strength lies in its adaptability—it can be tailored from simple to highly complex applications to precisely meet a facility's unique throughput, space, and product mix requirements. When implemented with careful consideration of all influencing factors and the total cost of ownership, a robotic palletizer becomes a strategic investment that enhances efficiency, optimizes space, and provides the agility to adapt to future business needs.