Receiving

Receiving is the inbound warehouse process where shipments arrive, are verified, inspected, and documented before entering inventory, establishing the foundation for accurate warehouse operations.

🧠 Receiving Operations Overview

Interactive overview of key receiving components - click to explore each category

Appointment Scheduling

Unloading Systems

Quality Inspection

Documentation

Process Flow and Business Characteristics

The receiving workflow begins when inbound trucks arrive at the facility, typically with advance notice through appointment scheduling systems or advanced shipping notices (ASN) from suppliers. Modern operations use dock scheduling software to assign specific time slots and dock doors, preventing congestion and optimizing labor allocation. The check-in process verifies driver credentials, reviews shipping documentation, and directs trucks to assigned docks based on product type, priority, or unloading requirements.

Unloading operations vary significantly based on product characteristics and facility capabilities. Floor-loaded containers require manual unloading where workers remove individual boxes or cases, a labor-intensive process taking 2-4 hours per container. Palletized shipments enable faster unloading using forklifts or pallet jacks, typically completing in 30-60 minutes. Live unload operations have drivers wait while unloading occurs, creating time pressure to minimize detention charges, while drop trailer programs allow drivers to leave trailers for unloading at the facility's convenience.

Documentation verification compares physical shipments against purchase orders, packing slips, and ASN data to identify discrepancies before products enter inventory. Staff verify supplier information, product identifiers, quantities, and lot numbers match expectations. Blind receiving (counting without reference to expected quantities) forces accurate counting but requires more time, while directed receiving (comparing counts to expected quantities) is faster but may lead to confirmation bias. The choice depends on operational priorities around accuracy versus speed.

Quality inspection examines products for transit damage, packaging integrity, expiration dates, and specification compliance. Inspection intensity varies by product risk (high-value, perishable, or quality-sensitive items receive more scrutiny), supplier performance (new or problematic suppliers face stricter inspection), and regulatory requirements (food, pharmaceuticals, and hazardous materials have mandatory checks). Sampling plans balance thoroughness against efficiency, inspecting representative samples rather than every unit for most products.

Automation Technologies

Dock scheduling systems optimize truck arrivals through online portals where carriers book appointments, with the system balancing workload across docks and shifts. These platforms integrate with transportation management systems (TMS) and warehouse management systems (WMS) to coordinate inbound flows with facility capacity. Advanced systems use predictive analytics to forecast arrival patterns and recommend optimal scheduling, reducing wait times by 40-60% while improving dock utilization.

Barcode scanning and RFID technology automate data capture during receiving, eliminating manual data entry errors and accelerating processing. Workers scan product barcodes and license plate labels to record receipts, with the system automatically updating inventory and generating putaway tasks. RFID readers at dock doors can capture entire pallet loads simultaneously, enabling touchless receiving where products are recorded without manual scanning. This technology improves accuracy from 95-98% (manual) to 99%+ while reducing receiving time by 30-50%.

Automated dimensioning and weighing systems capture product characteristics as items pass through receiving, verifying that physical dimensions and weights match master data. These systems detect mislabeled products, incorrect packaging, or concealed damage that affects weight. The data supports slotting optimization (assigning products to appropriate storage locations) and freight audit (verifying carrier charges). Integration with WMS enables automatic validation against expected specifications.

Vision systems and AI inspection use cameras and machine learning to detect packaging damage, label quality, and product defects without manual inspection. These systems can inspect 100% of products at line speed, identifying issues that human inspectors might miss due to fatigue or distraction. Damage detection algorithms flag crushed boxes, torn packaging, or leaking containers, while OCR (optical character recognition) verifies label accuracy and expiration dates.

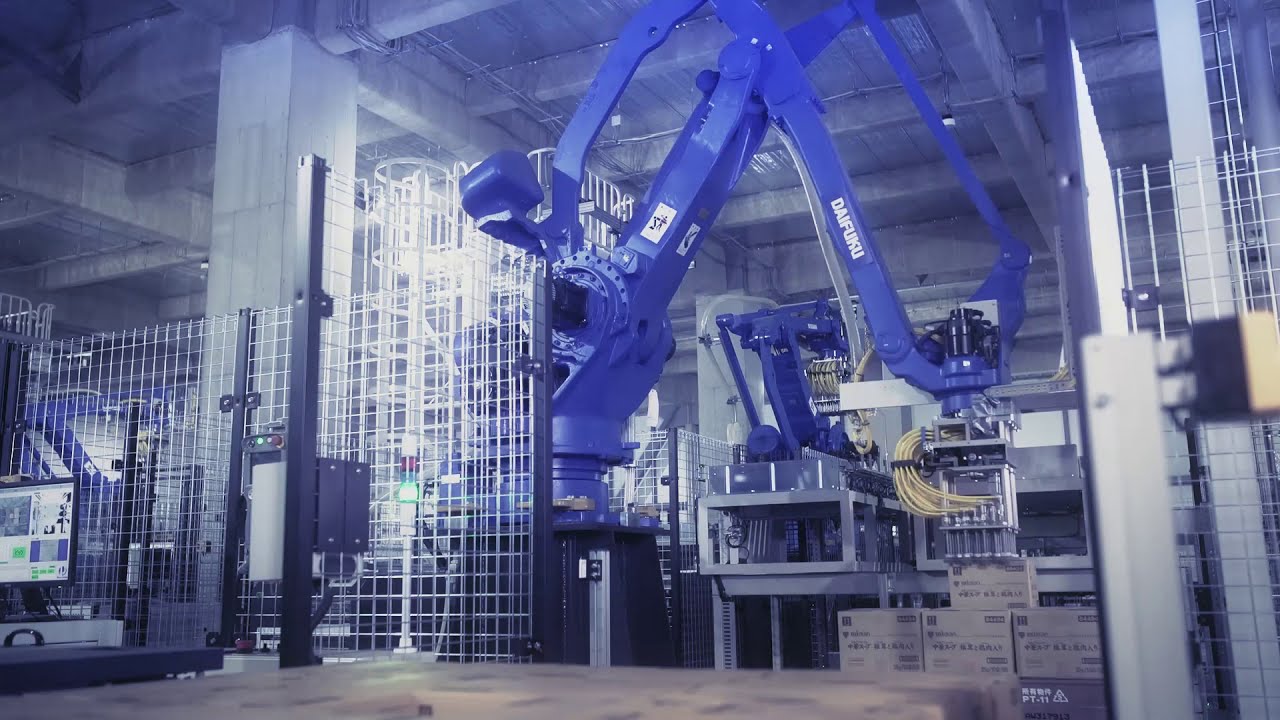

Automated unloading systems including robotic depalletizers, conveyor extensions, and automated guided vehicles (AGVs) reduce manual labor in unloading operations. Robotic systems can unload floor-loaded containers, identifying and grasping individual boxes to place on conveyors. Extendable conveyors reach into trailers, enabling workers to place boxes on conveyors rather than carrying them out. AGVs transport pallets from dock doors to staging areas, eliminating forklift travel and improving safety.

Key Performance Indicators

Receiving accuracy measures the percentage of receipts recorded correctly in the system, with targets typically 99%+ for automated operations and 95-98% for manual processes. Accuracy is measured by comparing physical counts to system records during cycle counting or inventory audits. Root cause analysis of discrepancies identifies whether errors occur during counting, data entry, or supplier shipping, enabling targeted improvements.

Dock door utilization tracks the percentage of time docks are actively processing shipments versus sitting idle, with targets of 70-85% during operating hours. Low utilization indicates scheduling problems, labor shortages, or equipment constraints, while excessive utilization (>90%) suggests insufficient capacity for peak periods. Appointment compliance (percentage of trucks arriving within scheduled windows) affects utilization, with late arrivals disrupting schedules and reducing efficiency.

Receipts per labor hour measures productivity, varying significantly by product type and handling method. Palletized goods typically achieve 15-25 pallets per labor hour, while floor-loaded containers average 200-400 pieces per labor hour depending on product size and weight. Automation can improve productivity by 30-50%, while process improvements (better scheduling, improved layouts, training) deliver 10-20% gains. Tracking productivity by product type, supplier, and shift identifies improvement opportunities.

Truck turnaround time measures how long trucks spend at the facility from arrival to departure, with targets typically under 60 minutes for palletized loads and 2-4 hours for floor-loaded containers. Excessive turnaround time results in detention charges from carriers and supplier complaints about delivery efficiency. Appointment scheduling, adequate labor, and efficient processes are key to minimizing turnaround time while maintaining quality.

Damage and discrepancy rates track the percentage of receipts with quality issues, quantity variances, or wrong items, with targets typically under 1-2%. High rates indicate supplier quality problems, carrier handling issues, or inadequate inspection processes. Supplier scorecards tracking these metrics support performance discussions and continuous improvement initiatives with the supply base.

By implementing effective receiving processes supported by appropriate automation technologies, warehouses establish accurate inventory records, prevent quality issues from entering operations, and create efficient inbound flows that support overall facility performance.