Automated Bagging Line with Robotic Palletizing: Integrated Solution

⚡Quick Facts

Technology Performance Metrics

⭐Key Features

✨Benefits

🎯Applications

📝Detailed Information

Technology Overview

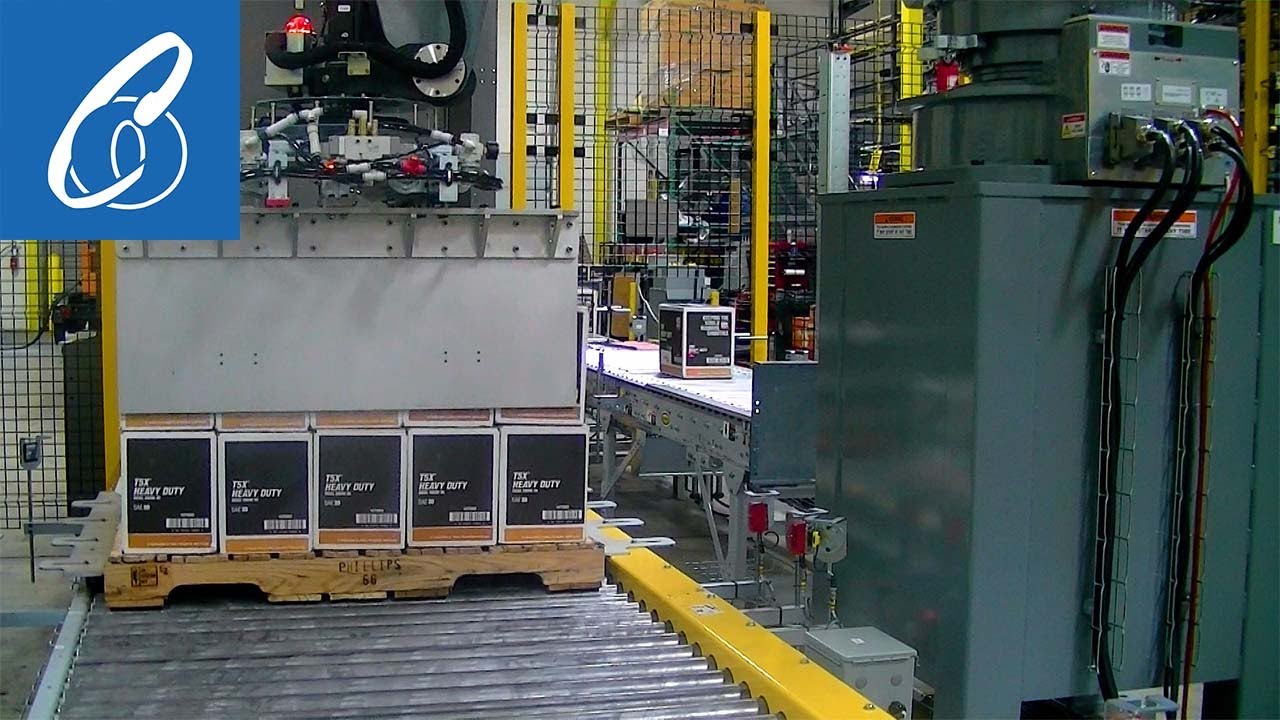

This technology describes a comprehensive, integrated automation solution for production lines that handle bagged goods. It combines the processes of bag filling and palletizing into a seamless, fully automated line. Provided by a single Original Equipment Manufacturer (OEM), the solution aims to eliminate the complexities of sourcing and integrating disparate equipment from multiple vendors. It is particularly relevant for industries producing powdered, granular, or other products packaged in bags, seeking to improve efficiency and consistency from the end of the production process through to warehouse-ready pallets.

How It Works

Core Principles

The core principle is the integration of upstream bagging operations with downstream robotic palletizing. The system is designed so that bags are automatically filled, sealed, and conveyed directly to a robotic palletizing cell, where a robot stacks them onto pallets in a pre-defined pattern, creating a continuous, hands-off material flow.

Key Features & Capabilities

Integrated End-to-End Solution: The most significant feature is the provision of a complete line from a single provider. This covers the entire scope from the bagging machine infeed to the outgoing pallet conveyor, including all mechanical, electrical, and control system integration.

Versatile Bagging Machine Integration: The system is designed to integrate with a wide range of bagging technologies, including open-mouth, form-fill-seal, and valve bag systems, allowing it to be tailored to specific product types and packaging requirements.

Single-Source Supply and Expertise: As the exclusive American distributor for STATEC BINDER bagging machines, Columbia/Okura can provide specialized, high-performance bagging equipment as part of the integrated package, offering customers technical expertise and responsibility for the entire line's performance.

Advantages & Benefits

The primary benefit is operational simplification and risk reduction. Having one provider responsible for the entire line design, component supply, integration, and commissioning streamlines project management and ensures accountability. This integrated approach can lead to faster implementation, optimized line performance, and easier troubleshooting and support. Automation increases throughput, reduces labor costs, and improves workplace safety by removing personnel from repetitive and potentially strenuous tasks.

Implementation Considerations

Implementing such a system is a significant capital project that requires detailed analysis of product characteristics, desired bag types, production rates, and facility layout. The single-source advantage comes with the trade-off of vendor lock-in for core components. Facilities must ensure they have the necessary utilities (compressed air, dust collection) and space for the integrated line. The project scope includes not just equipment installation but also comprehensive programming and testing of the entire interconnected system.

Use Cases & Applications

Ideal For

This solution is ideal for manufacturers in bulk goods industries (chemical, agricultural, food processing, building materials) who are building a new packaging line or undertaking a major modernization of an existing one, and who value the simplicity and assurance of a single, turnkey provider.

Performance Metrics

Performance is measured by the overall line efficiency (bags per hour) and reliability. A well-integrated system minimizes downtime between the bagging and palletizing stages. Key metrics include bag weight accuracy, bag seal integrity, palletizing cycle time, and overall equipment effectiveness (OEE). The return on investment is driven by labor savings, increased output, and reduced product giveaway or loss.

Conclusion

For producers of bagged goods, an integrated automated bagging and palletizing line represents a strategic investment in modern, efficient production. The single-source model offered by providers like Columbia/Okura reduces implementation complexity and provides a cohesive system designed for high performance. By automating the entire process from filling to palletizing, companies can achieve significant gains in productivity, consistency, and safety, positioning themselves competitively in their respective markets.