Integrated Robotic Palletizing and Stretch Wrapping System

⚡Quick Facts

Technology Performance Metrics

⭐Key Features

✨Benefits

🎯Applications

📝Detailed Information

Technology Overview

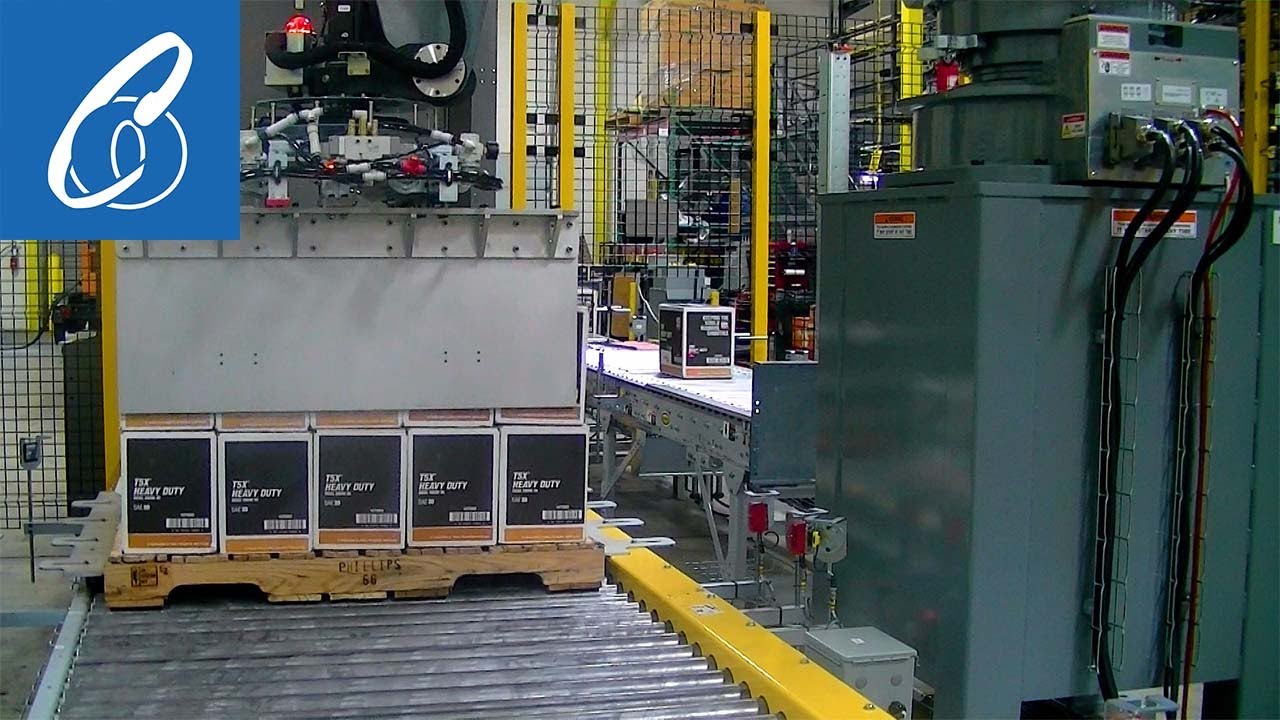

This technology represents an advanced, integrated automation solution for the final stages of production and shipping lines. Developed by Cross Company, it combines two critical end-of-line processes—robotic palletizing and stretch wrapping—into a single, cohesive system. The core innovation lies in interleaving these processes: rather than completing an entire pallet load before wrapping, the system performs incremental wrapping between layers as the robot stacks boxes. This approach fundamentally improves load stability, particularly for challenging products, while maintaining high throughput. It addresses common pain points in packaging operations, such as product shift during stacking, manual labor requirements, and safety concerns.

How It Works

Core Principles

The system operates on the principle of synchronous palletizing and wrapping. A robotic arm picks and places boxes onto a pallet in a programmed pattern. At predetermined intervals (e.g., after completing a layer), the robot pauses its stacking sequence. The integrated stretch wrapper then applies film to the partially built load. This cycle of stacking and incremental wrapping continues until the pallet is complete and fully wrapped.

Key Features & Capabilities

Incremental (Layer-by-Layer) Wrapping: This is the system's defining feature. By wrapping the load at multiple stages during its construction, it locks each layer in place before the next is added. This dramatically increases the stability of the final pallet, making it possible to securely stack even small, lightweight, or top-heavy boxes that might otherwise collapse.

Versatile Multi-Zone Vacuum Gripper: The custom-designed EOAT is a key enabler of flexibility. Its multi-zone vacuum system allows it to adaptively pick different sized boxes, as well as handle flat items like slip sheets and the pallet itself. This eliminates the need for multiple dedicated tools or manual intervention, streamlining the entire operation within a single robotic cell.

High-Speed Integrated Operation: The system achieves a palletizing rate of 20 boxes per minute while performing the wrapping process concurrently. This is accomplished through precise coordination between the robot and the wrapper, minimizing cycle time pauses and ensuring the integrated process does not become a bottleneck.

Advantages & Benefits

The foremost benefit is superior load stability and safety. Incremental wrapping virtually eliminates box shifting and load collapse, reducing product damage and creating safer, more transportable pallets. This leads to increased operational efficiency through consistent, high-speed automation that reduces dependency on manual labor for both stacking and wrapping. The system also offers labor and risk reduction by minimizing worker involvement in repetitive and potentially injurious tasks. Finally, the versatile gripper simplifies the process flow, reducing complexity and potential points of failure.

Implementation Considerations

Implementing such an integrated system requires careful engineering to seamlessly synchronize the robotic palletizer and the stretch wrapper, which are typically standalone machines. The programming logic for the interlaced stacking and wrapping sequences is more complex than for a standard palletizing cell. Facilities must consider the footprint for the combined system and ensure maintenance teams are trained on both robotic and wrapping technologies.

Use Cases & Applications

Ideal For

This system is ideal for manufacturing and distribution facilities that handle a mix of box sizes, particularly those containing lightweight, unstable, or fragile products (e.g., empty containers, cereal boxes, foam products) where load integrity during build-up and transit is a major concern.

Performance Metrics

The system delivers a demonstrated throughput of 20 boxes per minute. Key performance gains are in load stability (near elimination of collapse for unstable items) and labor reduction by automating two sequential processes.

Conclusion

The integrated robotic palletizing and stretch wrapping system represents a significant step forward in end-of-line automation. By merging two processes and executing them in an interlocked manner, it solves a fundamental problem of load stability while maintaining high throughput. For operations struggling with product damage, manual labor costs, or safety issues related to pallet building, this technology offers a robust, automated solution. While the integration is more complex than a standalone palletizer, the benefits in reliability, product protection, and efficiency make it a compelling choice for modern, high-volume packaging lines.