AMCAP: Automated Mixed Case Palletizing System

⚡Quick Facts

Technology Performance Metrics

⭐Key Features

✨Benefits

🎯Applications

📝Detailed Information

Technology Overview

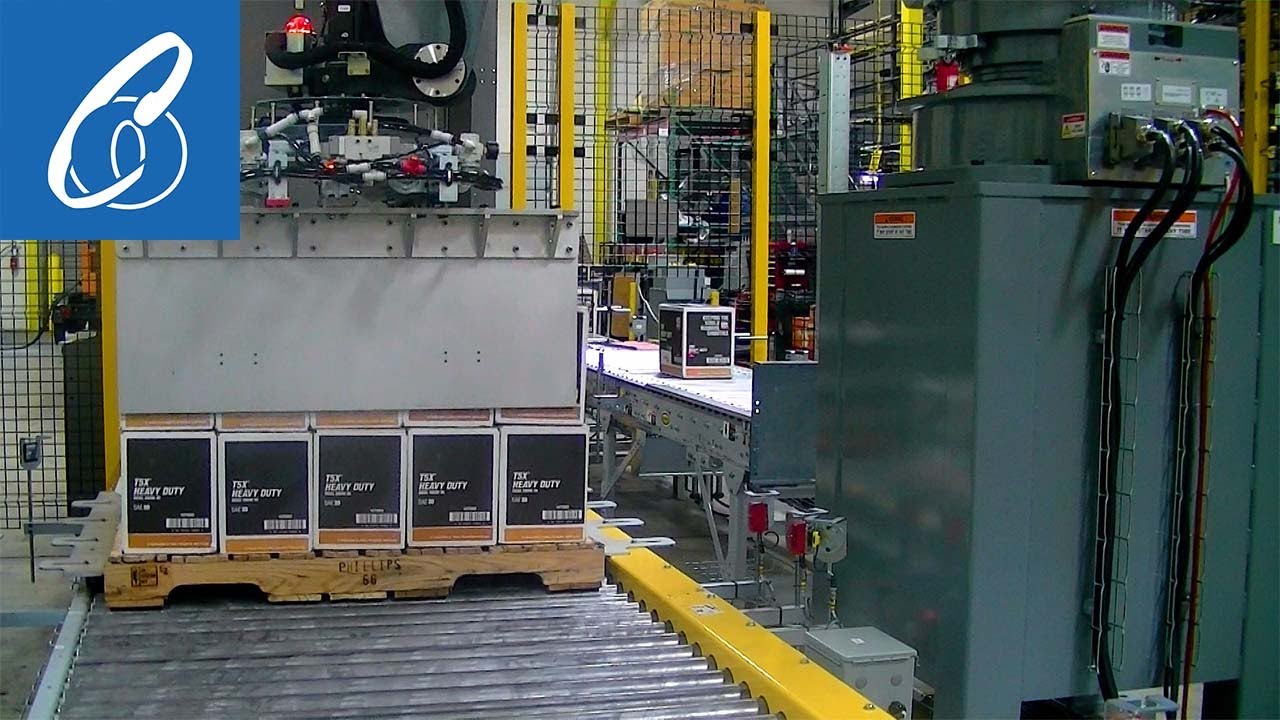

Dematic AMCAP (Automated Mixed Case Palletizing) is a comprehensive, high-performance automation solution designed to revolutionize case picking and palletizing for retail distribution, particularly in the grocery sector. It addresses the inherent inefficiencies and physical demands of traditional manual methods by creating a fully automated, integrated process. The system's primary objective is not just to automate pallet building, but to build pallets in a strategic sequence that mirrors the store's planogram (shelf layout). This "store-friendly" pallet approach aims to drastically reduce labor and time during shelf restocking at the retail store, while also optimizing shipping density and accuracy within the distribution center itself.

How It Works

Core Principles

The core principle is a goods-to-person palletizing process driven by automated storage, retrieval, and sequencing. Cases are stored in a high-density multi-shuttle buffer and retrieved in the exact sequence required to build a mixed pallet optimized for store shelf replenishment. The entire flow—from depalletizing full pallets of single SKUs, through buffering and sequencing, to building mixed pallets—is automated and software-controlled.

Key Features & Capabilities

Strategic Pallet Sequencing: This is the system's defining intelligence. The software builds pallets not just by stability, but by store restocking logic. Cases are arranged in the sequence they will be taken off the pallet and placed onto the store shelf, turning the pallet into a "pick path" for store associates.

High-Density Multi-Shuttle Buffer: The buffer system provides deep, compact storage for thousands of cases without secondary buffers. Its small footprint allows installation in existing spaces, including mezzanines, above docks, or within cold storage environments.

Integrated, Continuous Palletizing: The pallet build cell is designed for non-stop operation. The automatic pushing arms provide precise placement for high density, while the integrated slider plate allows the next pallet to be set up without interrupting the build cycle of the current one.

Advantages & Benefits

The primary benefit is a dramatic reduction in labor and injury risk by automating the physically demanding tasks of case picking and pallet building. It creates significant supply chain efficiencies by reducing store restocking time and stockouts through planogram-optimized pallets. Transportation costs are lowered through the creation of denser, cube-optimized pallets that make better use of trailer space. The system also offers a compact, retrofit-friendly design that can be deployed in existing distribution centers, even in space-constrained or temperature-controlled areas.

Implementation Considerations

Implementing AMCAP is a significant undertaking that involves integrating several complex automated subsystems. The success of the system heavily relies on the sophistication of its control software (WES) to manage sequencing, inventory, and pallet building logic. A thorough analysis of product data (dimensions, weight) and store requirements is needed upfront to configure the business rules. The investment is substantial and is typically justified by high case volumes and a strong focus on retail store efficiency.

Use Cases & Applications

Ideal For

AMCAP is ideally suited for high-volume grocery distributors, wholesale clubs, and retail chains that supply a large network of stores and are focused on optimizing the entire supply chain from DC to store shelf.

Conclusion

Dematic AMCAP represents a holistic approach to automating one of the most complex and costly links in the retail supply chain. It goes beyond simple mechanization to deliver intelligent pallet building that creates value both in the distribution center and at the retail store. While the system requires a significant investment and careful integration, for operations with sufficient volume and a strategic focus on store efficiency, it offers a compelling path to reduce labor costs, improve accuracy, accelerate replenishment, and lower total delivered cost per case. It is a benchmark solution for modern, automated mixed-case fulfillment.

📦Related Projects

Kesko Helsinki Micro-Fulfillment Center (MFC)

Kesko deployed Finland's first grocery micro-fulfillment center featuring a Dematic AutoStore system in a chilled environment, doubling daily volumes and enabling 6-hour delivery.

South West Healthcare Warrnambool Regional Logistics Distribution Centre

South West Healthcare deployed a Dematic AutoStore system to boost inventory capacity by 500% for its regional medical supply network, storing 6-8 weeks of stock in a reduced footprint.

Notions Marketing Distribution Center with Dematic CMMS - Grand Rapids

A 75-year-old distribution company transformed maintenance operations with Dematic CMMS, reducing reactive repairs by 50% while managing extensive conveyor and sorter networks for big-box retail fulfillment.