Automated Robot Palletizing System for Egg Producers

⚡Quick Facts

Technology Performance Metrics

⭐Key Features

✨Benefits

🎯Applications

📝Detailed Information

Technology Overview

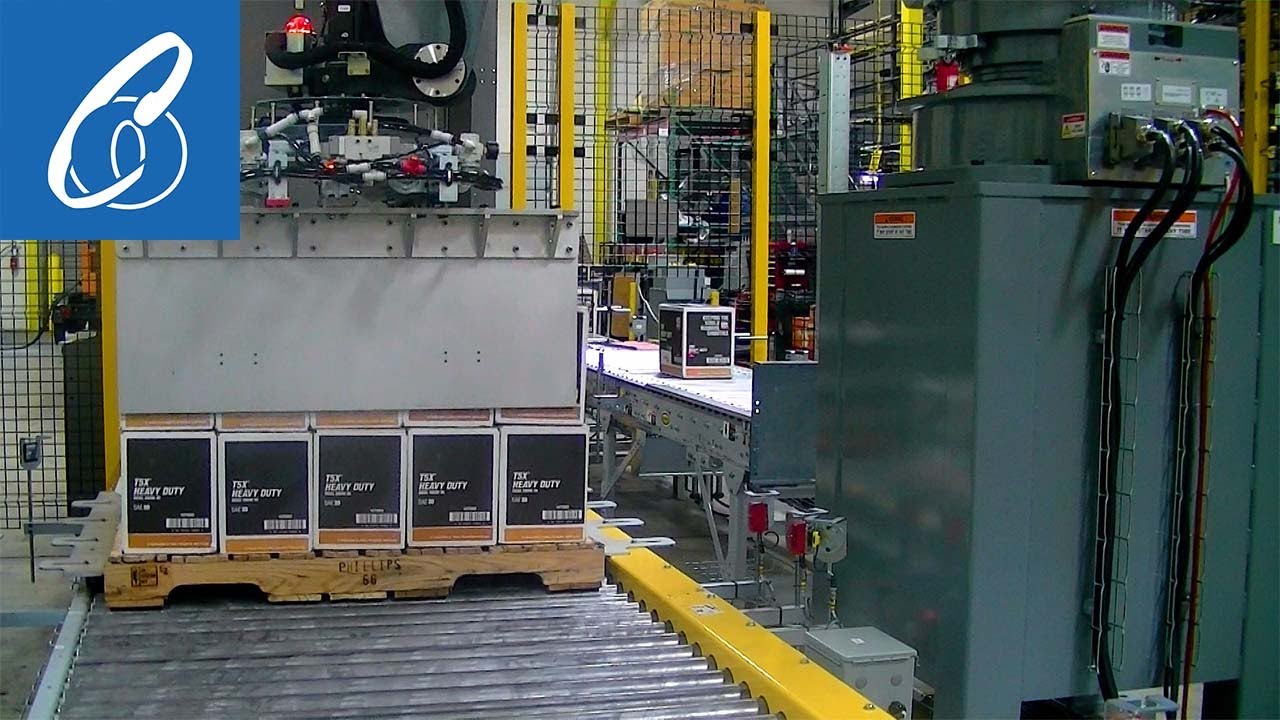

Automated robotic palletizing systems designed for egg producers address the unique challenge of handling a fragile, high-value product. These systems replace manual labor or conventional machinery with articulated robots equipped with specialized end-effectors. The core objective is to automate the process of stacking egg cartons or trays onto pallets while minimizing breakage and ensuring the load is stable for transportation. This technology is a key component in modernizing food production lines, particularly in industries where product integrity is paramount.

How It Works

Core Principles

The system operates on the principle of using a programmed robotic arm to pick and place egg cartons from a conveyor or infeed line onto a pallet. The robot's movements are precisely controlled to be smooth and gentle. The stacking pattern is pre-programmed into the system's software, which dictates the placement of each layer to create a interlocked, stable pallet load that can withstand the rigors of shipping.

Key Features & Capabilities

Gentle Handling for Fragile Products: The system is engineered with motion profiles and gripper technology that apply minimal force, ensuring delicate egg cartons are not damaged during the pick-and-place cycle.

Optimized Stacking Patterns: The palletizing software uses patterns specifically calculated to distribute weight evenly and interlock cartons, creating a stable load that prevents shifting and crushing during transport.

Application-Specific Design: Unlike general-purpose palletizers, this system is configured and tooled for the specific dimensions and fragility of egg packaging, making it a tailored solution for the poultry industry.

Advantages & Benefits

The primary benefit is a significant reduction in product loss due to breakage, directly impacting the producer's bottom line. Automation also improves workplace safety by removing personnel from repetitive lifting tasks and increases line throughput with consistent, uninterrupted operation. Furthermore, the standardized, stable pallets produced lead to fewer transportation claims and more efficient use of warehouse and trailer space.

Implementation Considerations

Implementing such a system requires careful analysis of the existing packaging line speed and carton specifications. The facility must have the necessary utilities (power, compressed air) and space for the robot cell and associated conveyors. Integration with upstream packaging equipment and downstream warehouse management systems should also be planned. The specialized nature of the gripper means it may not be easily adaptable to other, non-egg products without modification.

Use Cases & Applications

Ideal For

This technology is ideal for large-scale egg production and packaging plants where high volumes make manual palletizing inefficient and the cost of breakage is significant.

Performance Metrics

While specific throughput numbers (cases per hour) are not provided in the source, such systems are designed to meet or exceed the speed of manual operations while providing near-zero breakage rates when correctly implemented. The return on investment is driven by labor savings, reduced product waste, and lower shipping damage costs.

Conclusion

For egg producers facing challenges with labor, breakage, and shipping damage, an automated robotic palletizing system offers a compelling solution. By ensuring gentle handling and creating optimally stacked pallets, this technology safeguards product quality and improves operational efficiency. Companies like Columbia/Okura provide the necessary integration expertise to tailor these systems to the precise needs of the food production industry.