AI Vision-Enabled Robotic Depalletizing System

⚡Quick Facts

Technology Performance Metrics

⭐Key Features

✨Benefits

🎯Applications

📝Detailed Information

Technology Overview

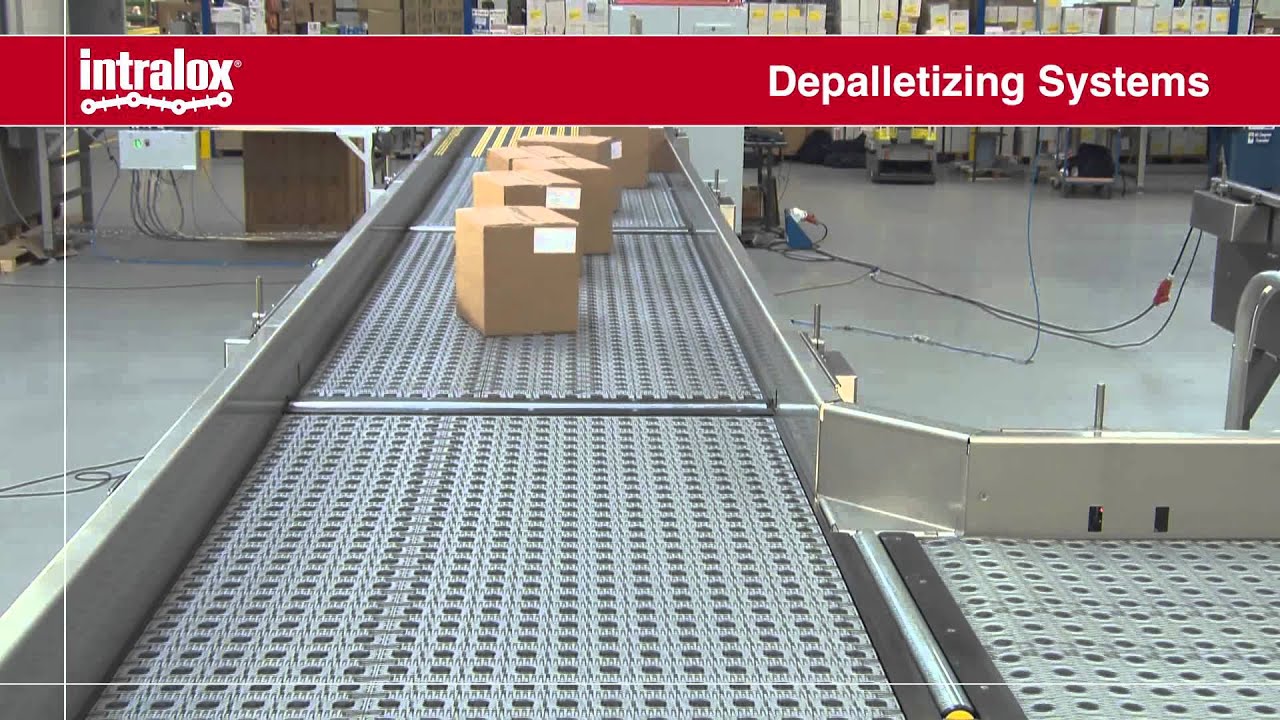

This AI vision-enabled robotic depalletizing system represents an advanced automation solution for the critical task of unloading inbound pallets in logistics, warehousing, and production environments. Developed by XYZ Robotics, the system is designed to tackle the variability and speed requirements of modern supply chains. By integrating a proprietary 3D vision system and artificial intelligence, the robot can perceive and identify a wide array of items on a pallet with exceptional accuracy. This perception capability, combined with high-speed robotic manipulation, allows the system to efficiently break down mixed-SKU pallets, handling everything from standard cartons and plastic totes to flexible bags and rigid barrels, thereby automating a traditionally manual and labor-intensive process.

How It Works

Core Principles

The core principle is vision-guided robotic picking. A proprietary 3D vision system scans the pallet load to create a detailed map of the items, their positions, orientations, and identities (likely via AI-based object recognition). This information is processed by an AI system that determines the optimal picking sequence and grip points. The robotic arm then executes the picks, utilizing multi-pick strategies (grabbing multiple items at once) where possible to maximize speed. The "teachless" motion refers to the robot's ability to calculate its own collision-free paths based on the 3D scene, reducing the need for manual programming of each possible scenario.

Key Features & Capabilities

High-Accuracy 3D Vision: The claimed 99.99% picking accuracy is a standout feature, critical for preventing missed picks, mis-picks, or damage caused by incorrect gripping. This level of reliability is essential for unattended automation.

High-Speed Multi-Pick Operation: Achieving 1200 cases per hour indicates a focus on throughput. The multi-pick capability (grabbing more than one case in a single robot cycle) is a key enabler of this speed, effectively reducing the number of robotic movements required per case.

Broad Item Flexibility: The ability to handle carton boxes, rigid totes, deformable bags, and cylindrical barrels demonstrates significant versatility. This suggests the system uses advanced perception to adapt its grip strategy and potentially employs a highly adaptable or multi-functional end-effector.

Advantages & Benefits

The primary advantage is the automation of a highly variable and physical task with both high speed and high accuracy, leading to major labor savings and ergonomic improvements. The exceptional 99.99% accuracy reduces product loss and operational disruptions caused by errors. The handling versatility future-proofs the investment against changes in packaged goods and makes it suitable for mixed-SKU environments like 3PL warehouses. High throughput supports faster receiving and processing cycles.

Implementation Considerations

The sophisticated vision and AI system represents a higher level of technological integration and cost compared to simpler automation. Successful handling of such diverse items (especially bags vs. rigid barrels) likely requires a sophisticated and possibly costly end-effector. Integration with upstream (pallet presentation) and downstream (conveyor/sortation) material handling is crucial to realize the full 1200 cases/hour potential.

Use Cases & Applications

Ideal For

This system is ideal for high-volume distribution centers, third-party logistics (3PL) providers, and manufacturing receiving docks that deal with a constant flow of diverse palletized goods and seek to fully automate the depalletizing process.

Conclusion

XYZ Robotics' AI vision-enabled depalletizing system addresses the complexity of modern inbound logistics with a powerful combination of advanced perception, intelligence, and speed. For operations burdened by the cost, variability, and physical strain of manual depalletizing, this technology offers a path to significant automation benefits. The high accuracy and versatility are particularly compelling for environments with diverse product flows. While the investment and integration complexity are considerations, the potential returns in labor productivity, processing speed, and operational reliability make it a compelling solution for forward-thinking logistics and warehouse operations aiming to automate one of their most fundamental tasks.

📦Related Projects

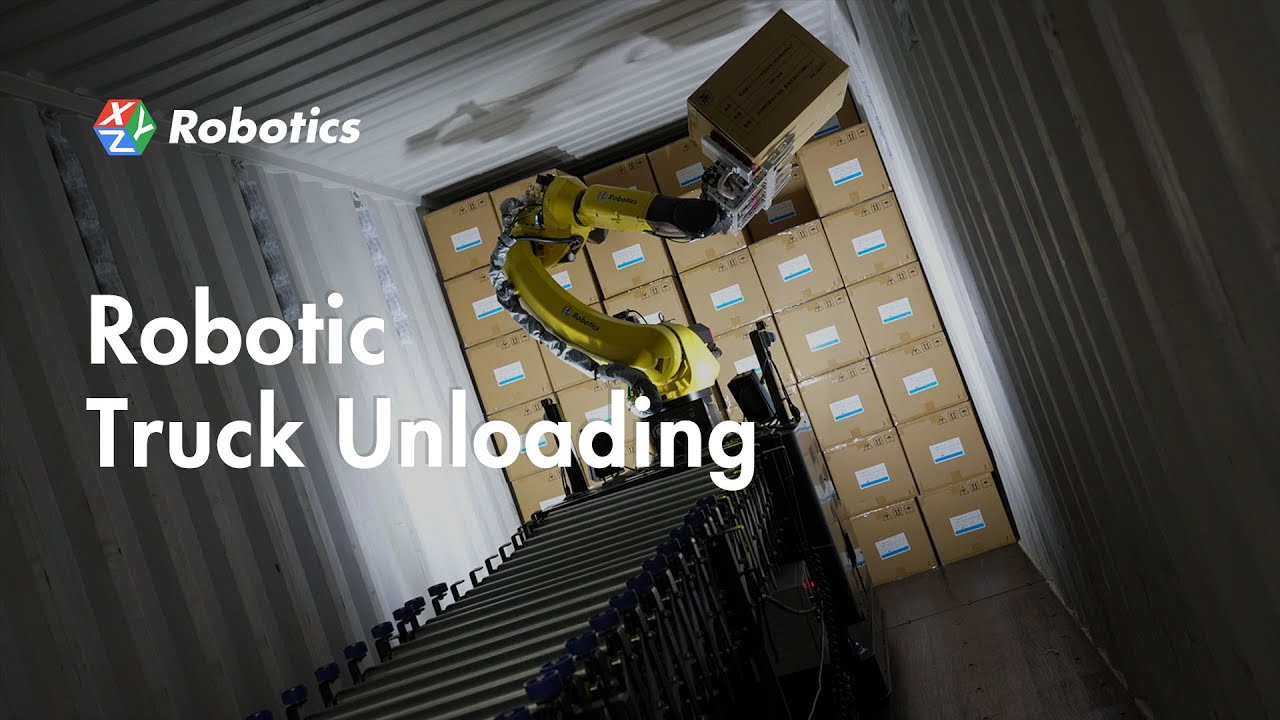

XYZ Robotics - Japanese 3PL Warehouse Robotic Truck & Container Unloading Project

XYZ Robotics deploys RockyOne Mobile Manipulation Robot to automate truck and container unloading for a Japanese 3PL warehouse, handling 15-kg cartons in 40-ft containers within 2 hours.

Dongfeng Motor R&D Center Smart Logistics Warehouse

A compact 470㎡ intelligent warehouse with 15-level high-density storage supporting 10,000+ SKUs for automotive R&D supply chain optimization.