Mini-Load ASRS: High-Density Goods-to-Person Storage

⚡Quick Facts

Technology Performance Metrics

⭐Key Features

✨Benefits

🎯Applications

📝Detailed Information

Technology Overview

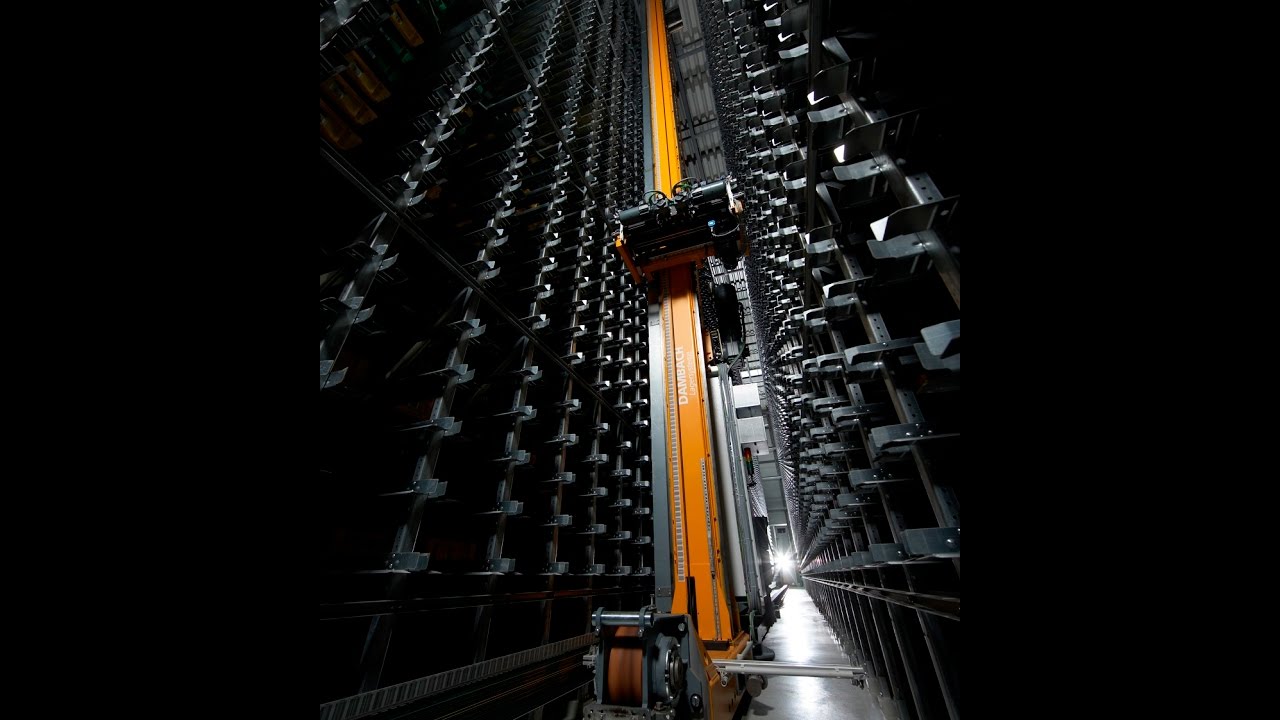

The Mini-Load Automated Storage and Retrieval System (ASRS) is a specialized technology designed to automate the handling of small unit loads, revolutionizing inventory management in modern warehouses. It addresses the critical need to optimize space and improve operational efficiency in fast-paced distribution and manufacturing environments. As a type of goods-to-person automation, it stores items in a high-density rack structure and delivers them directly to an operator or workstation upon request. Built with lightweight, durable alloys, it offers a cost-effective balance between performance, density, and investment. The system is particularly well-suited for handling cartons, totes, and trays weighing less than 350 pounds, making it ideal for managing a vast array of SKUs in e-commerce, pharmaceuticals, and assembly component storage.

How It Works

Core Principles

The core principle is automated, high-density storage and precision retrieval. A computer-controlled stacker crane operates within a narrow aisle of multi-level racking, automatically storing and retrieving individual bins or trays based on commands from the Warehouse Control System (WCS).

Key Features & Capabilities

High-Density Vertical Storage is its primary feature. By utilizing very narrow aisles and the full building height, it can achieve up to 85% savings in previously wasted overhead space, dramatically increasing storage capacity within the same footprint.

Integrated Inventory Management Software provides real-time visibility and control. The system software not only directs the cranes but also enforces inventory policies like FIFO (First-In, First-Out) or LIFO (Last-In, First-Out), manages batch numbers, and ensures accurate, auditable transaction records.

Modular Design for Mid-Range SKUs allows it to be effectively combined with other technologies. It can serve as the reserve storage buffer for faster-moving SKUs held in adjacent flow racks or static shelving, creating a hybrid, optimized storage solution.

Advantages & Benefits

The most significant advantage is substantial labor savings and reallocation. By automating the physically demanding and time-consuming tasks of searching, retrieving, and putting away items, it can reduce associated labor needs by up to two-thirds, allowing staff to focus on higher-value activities.

It delivers exceptional accuracy and inventory integrity. With a picking accuracy rate of 99.9%, it virtually eliminates mis-picks and lost inventory. Combined with secure, controlled access, it significantly reduces shrinkage and improves order fulfillment quality.

The system provides a strong return on investment through space savings and efficiency. The high density delays or eliminates the need for facility expansion, while the automation speeds up order cycle times and improves overall throughput, making it a cost-effective automation entry point.

Implementation Considerations

A thorough analysis of current operations is essential. Businesses must quantify existing labor hours for storage/retrieval tasks and evaluate their facility's vertical space potential to accurately model the ROI and justify the investment.

Proper system sizing is critical. The design depends on two key parameters: the total number of storage locations needed (inventory profile) and the required throughput (transactions per hour). This determines the number of aisles and cranes required.

Integration with upstream and downstream processes must be planned. Considerations include how items are delivered to and from the ASRS (manual vs. conveyor), how it interfaces with picking stations, and how data flows with the Warehouse Management System (WMS).

Use Cases & Applications

Ideal For

This technology is ideal for e-commerce fulfillment centers, pharmaceutical warehouses, electronics assembly, and any operation that manages a high number of SKUs in small containers and requires fast, accurate access to support order picking, kitting, or production lines.

Performance Metrics

Key performance metrics highlighted include:

- Labor Reduction: Up to two-thirds reduction in labor needs for storage/retrieval tasks.

- Picking Accuracy: 99.9% accuracy rate.

- Space Savings: Up to 85% savings in underutilized overhead space, translating to vastly increased storage density.

- Load Capacity: Handles loads typically under 350 pounds (approx. 160 kg).

Conclusion

The Mini-Load ASRS presents a powerful and pragmatic automation solution for businesses aiming to maximize their warehouse cube, drastically improve inventory accuracy, and reduce labor costs. Its strength lies in its focused design for small-item storage, offering a compelling mix of high density, precision, and cost-effectiveness. For operations burdened by manual picking errors, space constraints, or inefficient storage practices, implementing a Mini-Load ASRS can be a transformative step. Success requires careful pre-implementation analysis, precise system sizing, and partnership with experienced integrators to ensure the technology is tailored to specific operational needs and seamlessly woven into the broader warehouse workflow.