AI Visual Inspection & Automated Packing Solution for Textiles

⚡Quick Facts

Technology Performance Metrics

⭐Key Features

✨Benefits

🎯Applications

📝Detailed Information

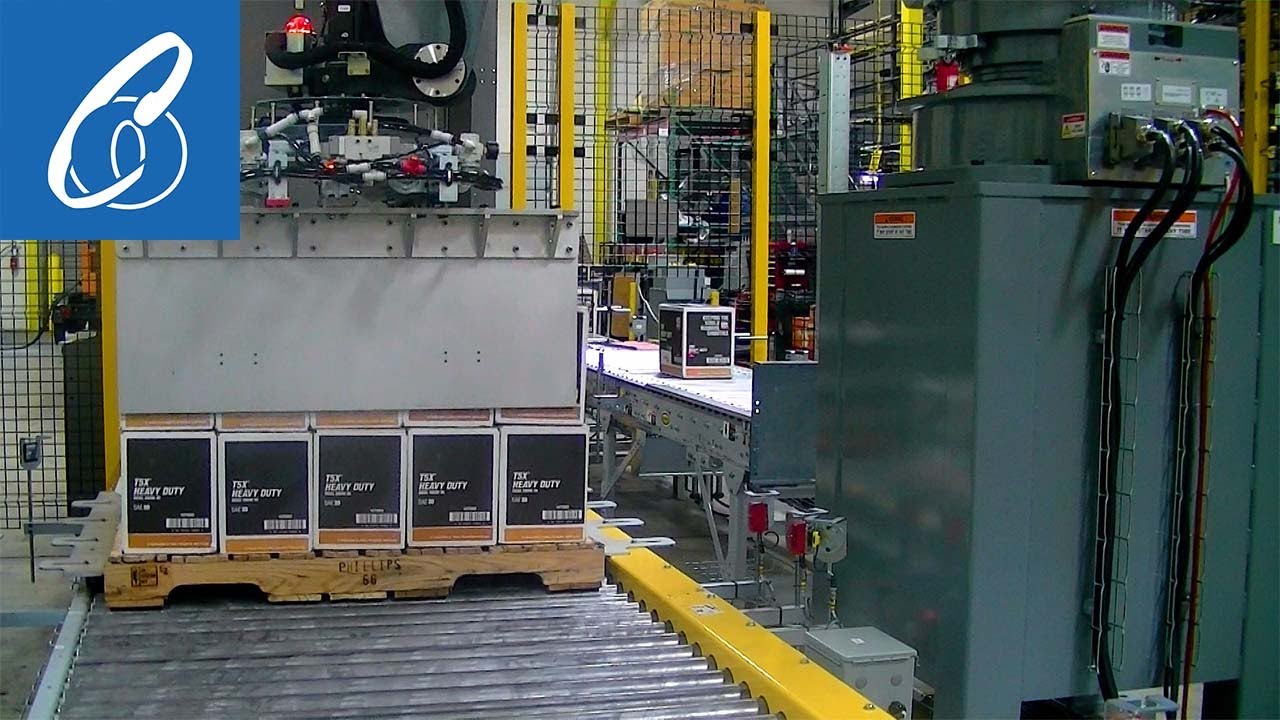

Technology Overview

SUNTECH's AI Visual Inspection & Automated Packing Solution is a comprehensive, end-to-end automation system specifically engineered for the textile manufacturing industry. It targets the post-production stages where fabric rolls are inspected, prepared, and packed for shipment. By seamlessly integrating advanced artificial intelligence for quality control with a suite of automated material handling and packing technologies, the solution aims to transform a traditionally manual and labor-intensive process into a highly automated, efficient, and reliable workflow. It positions itself as the premier choice for textile mills seeking to modernize their operations, improve product quality consistency, and significantly reduce labor dependency.

How It Works

Core Principles

The core principle is the closed-loop automation of the fabric finishing process, from quality inspection to ready-to-ship packaging, using AI as the "eyes" and decision-making engine, and robotics/AGVs as the "hands" for physical handling.

Key Features & Capabilities

The integration of AI-powered visual inspection is the cornerstone, providing high-precision, consistent quality control that surpasses human capability in speed and endurance. The system enables smart, autonomous handling of complex order profiles, such as small bulk and multi-batch orders, which are common challenges in textile fulfillment. The high-speed automated packing capability of 7 rolls per minute is a critical throughput feature. The seamless connectivity to ERP/MES systems ensures that the physical automation is fully synchronized with business and production data flows. The inclusion of AGVs for internal transport completes the material flow automation from production line to warehouse.

Advantages & Benefits

The primary benefits are a dramatic 7x boost in efficiency and significant cost savings through labor reduction and minimized errors. The solution enables highly automated production, making textile mills more competitive and resilient. The high detection precision (≥85%) of the AI inspection leads to a higher pass rate of finished fabric, directly improving product quality and customer satisfaction. Guaranteed quality and safety are achieved through consistent, automated processes. The system future-proofs operations by digitizing and automating core post-production processes.

Implementation Considerations

This is a major, integrated automation project specific to the textile industry, requiring substantial capital investment and space. Integration with the mill's existing ERP/MES is crucial for realizing the full benefits of data synchronization and orderly management. The system's performance, particularly the AI inspection, depends on high-quality data and training for specific fabric types and defects. Change management and training for existing staff to operate and maintain the new automated system are essential. The throughput (7 rolls/min) must align with the mill's production volume to justify the investment.

Use Cases & Applications

Ideal For

This solution is ideal for medium to large textile mills producing fabric rolls (e.g., for apparel, home textiles, industrial fabrics) that seek to automate their finishing, inspection, and packing operations to improve quality, speed, and reduce labor costs.

Performance Metrics

The content provides specific performance claims:

- Efficiency Boost: 7 times (7X) improvement.

- Inspection Precision: ≥85% detection precision.

- Packing Speed: 7 rolls per minute (meeting European standards).

Conclusion

SUNTECH's AI Visual Inspection & Automated Packing Solution represents a transformative leap for the textile industry, addressing long-standing inefficiencies in post-production processes. By combining cutting-edge AI with robust automation hardware, it offers a path to unprecedented levels of productivity, quality control, and operational cost reduction. For textile mills ready to invest in the future of manufacturing, this integrated system provides a compelling solution to achieve fully automated, smart production that can enhance competitiveness, ensure consistent quality, and meet the complex demands of modern markets.