Automated Packing Systems

Intelligent automated packing systems that combine advanced robotics, machine vision, and AI-driven software to transform individual product packing operations, delivering unprecedented speed, consistency, and efficiency in modern fulfillment centers.

Core Technology

- • Multi-axis robotic arms

- • 3D machine vision systems

- • Intelligent control software

- • Automated packaging equipment

- • Real-time optimization

System Components

- • Robotic handling systems

- • Vision and sensing equipment

- • Box forming machines

- • Void fill dispensers

- • Sealing mechanisms

Applications

- • E-commerce fulfillment

- • Pharmaceutical packaging

- • Electronics manufacturing

- • Food and beverage

- • Cosmetics packaging

Benefits

- • 24/7 operation capability

- • Consistent packing quality

- • Reduced labor costs

- • Optimized material usage

- • Improved safety

Implementation

- • Requirements analysis

- • System design and selection

- • Installation and integration

- • Testing and validation

- • Staff training programs

Considerations

- • Initial investment cost

- • Product standardization needs

- • Space requirements

- • Maintenance complexity

- • Integration challenges

Key Performance Metrics

Intelligent Product Recognition and Handling

At the heart of every automated packing system lies sophisticated machine vision technology that can instantly identify, measure, and assess products as they arrive at the packing station. 3D scanning systems create detailed digital models of each item, analyzing dimensions, weight distribution, and fragility characteristics to determine optimal packing strategies. This intelligence enables systems to handle diverse product portfolios without manual programming or setup changes.

Advanced robotic handling systems utilize multi-axis articulated arms equipped with adaptive end-effectors that can securely grasp products of varying shapes, sizes, and materials. Force-feedback sensors ensure gentle handling of fragile items while maintaining the speed necessary for high-throughput operations. The integration of collaborative robotics allows these systems to work safely alongside human operators when manual intervention is required.

Dynamic Container Optimization

Modern automated packing systems excel at intelligent container selection, utilizing algorithms that analyze product dimensions and characteristics to select the most appropriate packaging from available options. Real-time optimization engines consider factors such as product protection requirements, shipping costs, and sustainability goals to make optimal packaging decisions for each individual order.

Automated box forming and bag insertion systems prepare containers precisely when needed, eliminating waste and reducing storage requirements. Variable-height box forming technology creates custom-sized containers that perfectly fit product dimensions, minimizing void space and reducing packaging material consumption. This dynamic approach to container optimization can reduce packaging costs by 15-30% while improving product protection.

AI-Powered Fulfillment and Logistics Robots

Vendor: Others

Precision Void Fill and Protection

Automated packing systems incorporate intelligent void fill dispensing that calculates the exact amount of protective material needed for each package. Air cushion systems, paper void fill dispensers, and foam-in-place equipment work in coordination with the main packing system to provide optimal product protection while minimizing material usage.

Pressure-sensitive dispensing ensures that fragile items receive appropriate cushioning without over-packing, while adaptive protection algorithms adjust void fill strategies based on shipping method, destination, and product characteristics. This intelligent approach to product protection significantly reduces damage rates while optimizing packaging efficiency.

Seamless System Integration

Advanced automated packing systems integrate seamlessly with warehouse management systems (WMS) and order management platforms to receive real-time order information and product specifications. API-based connectivity enables systems to access product databases, shipping requirements, and customer preferences to customize packing strategies for individual orders.

Real-time inventory management ensures that packaging materials are automatically replenished, while quality control integration tracks packing performance and identifies optimization opportunities. Predictive analytics analyze historical data to anticipate peak demand periods and optimize system performance accordingly.

RightPick2: Autonomous Piece-Picking Robot for Intralogistics

Vendor: RightHand Robotics, Inc.

Performance Excellence and Scalability

Modern automated packing systems achieve throughput rates of 800-1,500 packages per hour, depending on product complexity and packaging requirements. Adaptive speed control automatically adjusts packing velocity based on product characteristics, ensuring optimal balance between speed and quality. Multi-station configurations enable scalable capacity expansion as business requirements grow.

Continuous operation capabilities allow systems to run 24/7 with minimal supervision, while predictive maintenance systems monitor equipment health and schedule service activities to minimize unplanned downtime. Performance analytics provide detailed insights into system efficiency, enabling continuous optimization and improvement.

Quality Assurance and Compliance

Automated packing systems incorporate comprehensive quality control mechanisms that verify proper product placement, adequate protection, and correct labeling before packages leave the system. Weight verification systems ensure accurate packing, while vision inspection confirms proper sealing and labeling application.

Traceability systems maintain detailed records of packing activities, including timestamps, operator information, and quality metrics, supporting compliance requirements and enabling rapid issue resolution. Automated rejection systems remove packages that don't meet quality standards, ensuring consistent output quality and customer satisfaction.

Industry Applications and Benefits

Automated packing systems excel in e-commerce fulfillment environments where order diversity and volume fluctuations demand maximum flexibility. Pharmaceutical packaging applications benefit from the precision and traceability capabilities, while food and beverage operations leverage the hygienic design and gentle handling characteristics.

Return on investment typically occurs within 18-30 months through labor cost reduction, improved packing consistency, and reduced product damage. The ability to reallocate human workers to higher-value activities while maintaining consistent packing quality regardless of shift changes provides significant operational advantages. Sustainability benefits include reduced packaging waste, optimized material usage, and improved shipping efficiency through right-sized packaging.

🔧Related Technologies (6)

AI-Powered Fulfillment and Logistics Robots

byOthers

RightPick2: Autonomous Piece-Picking Robot for Intralogistics

byRightHand Robotics, Inc.

TiltSort-Bot: Autonomous Mobile Robot (AMR) for Sortation

by Conveyco

Dark Warehouse: Fully Automated Warehouse Operations

byAddverb

Movu Warehouse Execution System (WES): For Shuttle and AMR Management

byMovu Robotics

t-Sort Robotic Unit and Parcel Sortation System: Next-Generation E-commerce Order Fulfillment

byOther

About This Topic

📁Related Projects(6)

JD.com - Flexible Case Picking Automation with ForwardX Robotics AMRs

ForwardX Robotics

Alza Prague High-Throughput Fulfillment Center

Element Logic

Landmark Group Kuwait Fulfillment Center

Addverb

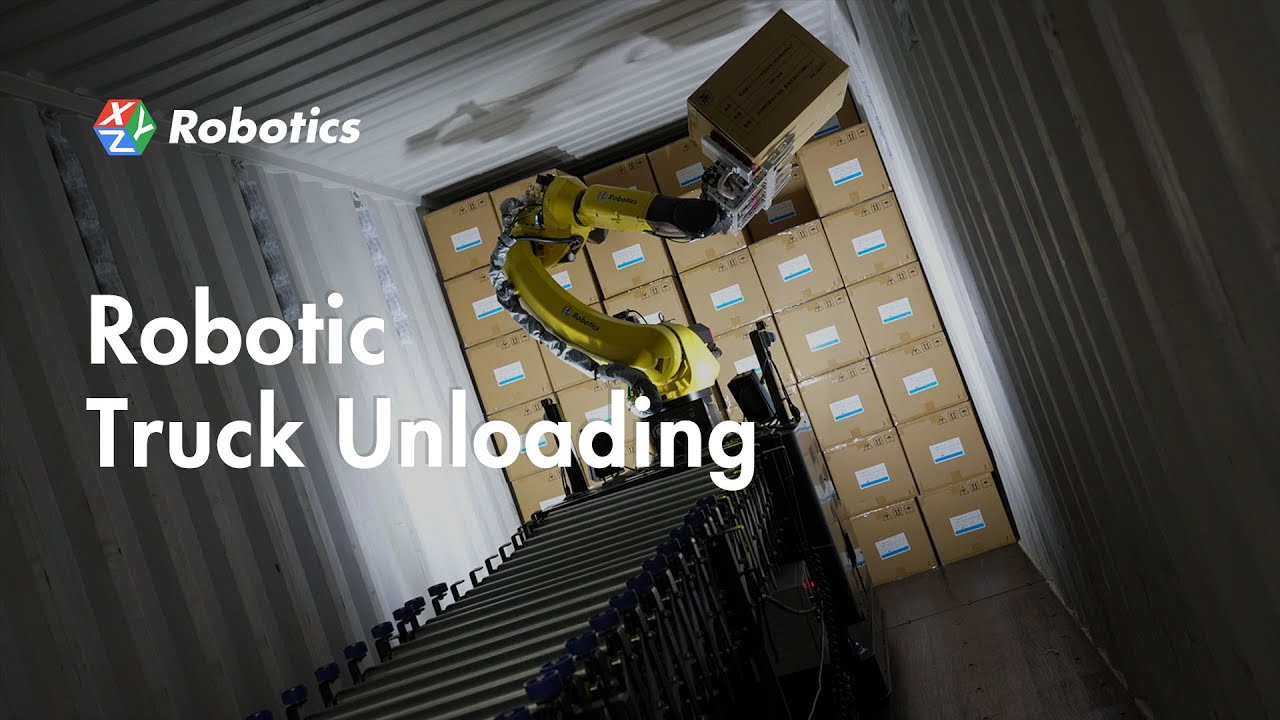

XYZ Robotics - Japanese 3PL Warehouse Robotic Truck & Container Unloading Project

XYZ Robotics

Dexterity AI & FedEx Parcel Hub Robotic Truck Loading Project

Dexterity AI

X-step Smart Warehouse

Geek+

🏢Related Suppliers(3)

Addverb

Warehouse Automation that delivers value!

Bastian Solutions

A Toyota Advanced Logistics Company

BlueSword Intelligent Technology Co., Ltd.

Pioneering global warehouse automation since 1993