Automotive Warehousing

Automotive warehousing supports manufacturing with just-in-sequence delivery, heavy component handling, and complex supply chain coordination, managing thousands of parts per vehicle across multiple variants and supplier networks.

🚗 Automotive Warehousing Ecosystem

Operations Profile

- •Thousands of parts per vehicle

- •JIT & JIS delivery

- •24/7 operations

- •Line-side delivery

Critical Challenges

- •Sequencing accuracy (99.9%+)

- •Heavy material handling

- •Model changeovers

- •Line stoppage costs ($1000s/min)

Storage Solutions

- •Heavy-duty AS/RS

- •Shuttle systems

- •Flow racks (FIFO)

- •Overhead storage systems

Transport Systems

- •AGV tugger trains

- •Overhead conveyors

- •Robotic palletizers

- •Automated sequencing systems

Tracking & Control

- •RFID real-time tracking

- •Vision systems (QC & verify)

- •Andon integration

- •Digital twin simulation

Software Systems

- •WMS with sequencing logic

- •MES integration

- •Supplier portals

- •Quality management systems

🌐 Industry Overview

Automotive warehousing serves one of the most demanding manufacturing environments, where assembly lines operate at precise takt times and any parts shortage stops production at enormous cost. These facilities manage thousands of components per vehicle—from small fasteners to heavy engines and transmissions—delivering them to assembly stations in exact sequence and timing. The complexity is compounded by multiple vehicle models, hundreds of configuration options, and networks of tier suppliers that must be precisely coordinated.

Two distinct operational models coexist: just-in-time (JIT) delivery of common parts used across many vehicles, and just-in-sequence (JIS) delivery of variant-specific parts in exact build order. JIS operations are particularly challenging—parts must arrive at the assembly line in the precise sequence matching the production schedule, often with only minutes of buffer. A single sequencing error can stop the entire line, making accuracy paramount.

🏭 Warehouse Operations Characteristics

Automotive warehouses operate as extensions of the assembly line, with receiving, storage, and sequencing activities synchronized to production schedules updated hourly or more frequently. Inbound logistics are carefully orchestrated, with milk runs collecting parts from multiple suppliers and cross-docking operations minimizing storage time. Many facilities operate 24/7 to support multi-shift assembly operations.

The physical environment is diverse. Bulk storage areas hold high-volume common parts (fasteners, brackets, standard components) used across many vehicles. Sequencing areas marshal variant-specific parts (seats, instrument panels, trim pieces) into build-order sequence. Heavy storage zones handle engines, transmissions, and axles with specialized racking and handling equipment. Kitting areas prepare sub-assemblies and tool sets for specific assembly stations.

Line-side delivery is the critical output. Tugger trains or AGVs transport parts to assembly stations on precise schedules, delivering the right parts at the right time to the right location. Empty container return logistics are equally important—reusable containers must flow back to suppliers for refilling. This closed-loop system requires careful tracking and management to prevent container shortages that would disrupt supply.

⚠️ Key Challenges

Sequencing accuracy is non-negotiable. Delivering the wrong part to an assembly station stops the line immediately, with costs measured in thousands of dollars per minute. JIS operations require perfect execution—parts must be selected, sequenced, and delivered in exact build order. This demands robust systems, well-trained staff, and multiple verification checkpoints. Even 99.9% accuracy is insufficient when processing thousands of parts daily.

Heavy material handling creates safety and equipment challenges. Engines and transmissions weigh hundreds of kilograms and require specialized lifting equipment, robust racking, and careful handling procedures. Worker safety is paramount—injuries from heavy material handling are costly and disruptive. Automation must be designed for these loads with appropriate safety systems and redundancy.

Model changeovers and variant proliferation increase complexity. New vehicle models require different parts, different sequencing logic, and often different handling equipment. Growing customization means more variants—a single model might have 50+ seat configurations, 20+ instrument panel variants, and countless trim combinations. Managing this complexity while maintaining sequencing accuracy and line-side delivery performance is increasingly challenging.

🤖 Suitable Technologies

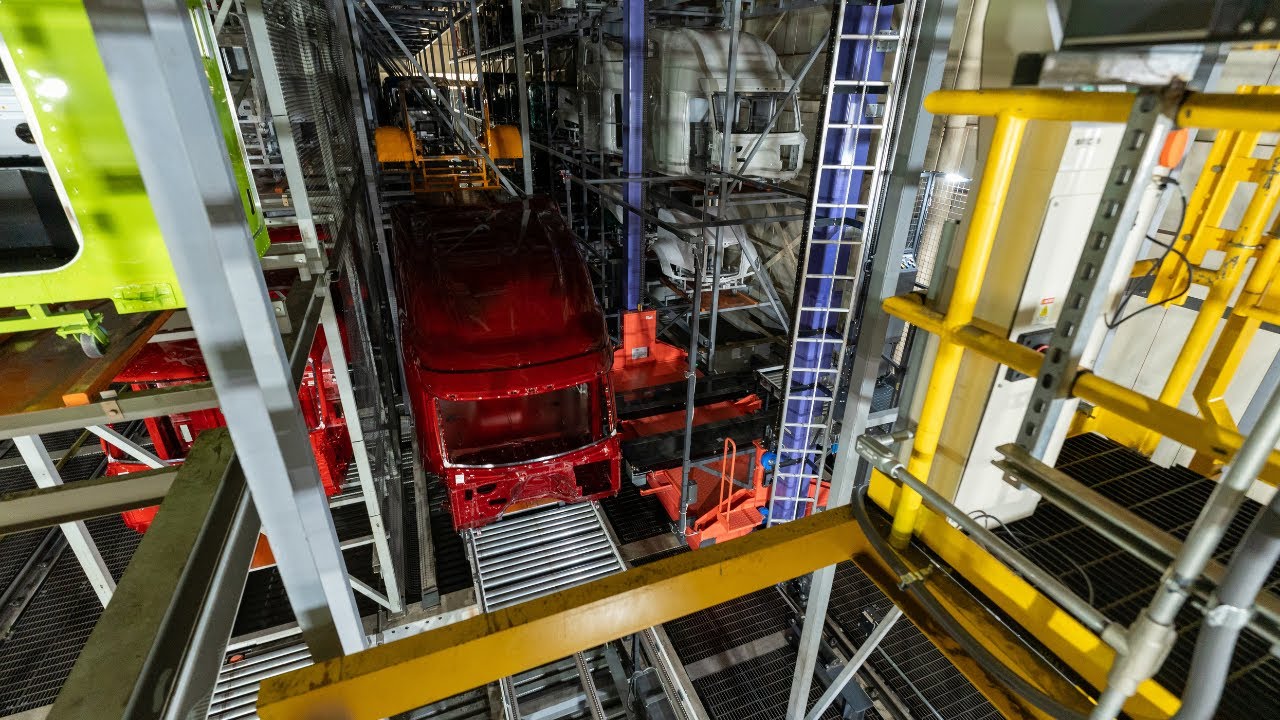

Storage Solutions: Heavy-duty AS/RS systems handle engines, transmissions, and other large components with specialized lifting mechanisms and robust construction. Shuttle systems provide high-density storage for small parts with rapid retrieval. Flow racks present parts in FIFO sequence for line-side picking. Overhead storage systems handle body panels and large components without consuming valuable floor space. All systems must integrate with sequencing logic to support JIS operations.

Transport Systems: AGVs and AMRs configured as tugger trains deliver parts to assembly stations on scheduled routes, replacing manual material handling. Overhead conveyors transport body-in-white components through paint and assembly processes. Robotic palletizers handle heavy components safely and consistently. Automated sequencing systems marshal parts into build order using conveyor networks and sortation technology.

Tracking and Control: RFID systems provide real-time visibility of part locations throughout the facility and on the assembly line. Vision systems automate quality inspection of incoming parts and verify correct sequencing. Andon integration connects warehouse operations to assembly line status—when the line stops, the warehouse knows immediately. Digital twin technology enables simulation and optimization of warehouse layouts and processes before physical implementation.

Software Systems: WMS with automotive-specific functionality manages inventory, sequencing, and line-side delivery. MES (Manufacturing Execution System) integration synchronizes warehouse operations with production schedules updated in real-time. Supplier portals provide visibility into inbound deliveries and enable collaborative planning. Quality management systems track defects, manage recalls, and ensure traceability from supplier through assembly.

🎯 Technology Selection Criteria

MES integration is critical—warehouse operations must synchronize with production schedules in real-time. Systems should receive production sequence updates and adjust picking and delivery accordingly. This integration is more complex than typical WMS implementations and requires deep understanding of automotive manufacturing processes.

Heavy material handling capability is essential for components like engines and transmissions. Automation must handle these loads safely with appropriate lifting mechanisms, robust construction, and comprehensive safety systems. Verify vendor experience with automotive applications—general warehouse automation may not be suitable for heavy automotive components.

Sequencing accuracy and verification are paramount. Systems should include multiple checkpoints to verify correct part selection and sequence. Vision systems, RFID verification, and manual confirmation steps all play roles. The cost of sequencing errors is so high that redundant verification is justified.

💡 Implementation Considerations

Start with bulk storage and JIT operations before tackling JIS sequencing. Common parts used across many vehicles are more forgiving of errors and provide learning opportunities. Prove automation reliability with simpler operations before implementing critical JIS processes where errors stop production.

Locate sequencing operations close to assembly lines to minimize delivery time and buffer requirements. Physical proximity reduces the time parts spend in the sequencing buffer, allowing more flexibility to respond to production schedule changes. Some operations integrate sequencing directly into assembly facilities rather than separate warehouses.

Plan for model changeovers from day one. Automotive facilities must adapt to new models every few years. Design flexible systems that can accommodate different part sizes, different sequencing logic, and different handling requirements. Modular automation that can be reconfigured is preferable to highly specialized systems that become obsolete with model changes.

Supplier collaboration is essential. Share production schedules in real-time so suppliers can synchronize their deliveries. Implement vendor-managed inventory for appropriate components. Establish quality agreements and conduct regular audits. Coordinate packaging standards to ensure supplier packaging is compatible with warehouse automation.

Change management focuses on quality and precision. Automotive operations demand different mindsets than general warehousing—accuracy takes precedence over speed. Workers must understand the impact of errors on assembly line operations. Plan for 12-18 months from project start to full operation for significant automation, with extensive testing and verification before going live with JIS operations.

🔧Related Technologies (6)

Mobile Picking Robot (MPR): Smart Logistics Automation

byHyundai

Electrified Monorail Systems (EMS): Overhead Assembly Line Conveyors

byOthers

I-Beam & Monorail Overhead Conveyors: Heavy-Duty Material Handling

byOthers

SSI SCHAEFER Miniload Crane (SMC): Automated Storage for Small Loads

bySSI Schaefer

Dematic Goods-to-Person AMR: Next-Generation Autonomous Mobile Robot

byDematic

Swisslog Vectura Pallet Stacker Crane: Energy-Efficient High-Bay AS/RS

bySwisslog

📚Related Topics

📊Manufacturing & Industrial Segment Comparison

Understanding the differences between manufacturing and industrial segments helps in selecting the right production support technologies and material handling strategies for your specific operation.

| Aspect | Manufacturing | Automotive | Electronics | Industrial |

|---|---|---|---|---|

| Primary Focus | Production line support, JIT delivery | Just-in-sequence assembly support | Component management, high-mix production | Project-based logistics, heavy equipment |

| Material Type | Raw materials, components, WIP | Heavy parts, engines, body panels | Small components, microchips, PCBs | Heavy equipment, bulk materials, machinery |

| SKU Complexity | Medium (1,000-10,000) | Very High (10,000-50,000+ per model) | Extremely High (10,000-100,000+) | Medium-High (5,000-20,000) |

| Handling Requirements | Mixed: Light to heavy | Heavy-duty, specialized equipment | ESD-safe, cleanroom, delicate | Heavy-duty cranes, forklifts |

| Storage Density | Medium-high density | Low-medium (heavy items) | Very high (small components) | Low (large equipment) |

| Delivery Method | JIT to production lines | JIS (just-in-sequence) | Kitting, SMT feeder prep | Project kitting, job site delivery |

| Inventory Turns | 12-20x per year | 20-30x per year (JIS) | 8-15x per year | 4-8x per year |

| Lead Time | Hours to days | Minutes to hours (JIS) | Days to weeks | Weeks to months |

| Special Requirements | MES integration, flexibility | Sequencing accuracy, heavy handling | ESD protection, humidity control | Hazmat compliance, outdoor storage |

| Automation Level | Medium-High (50-70%) | High (60-80%) | Very High (70-90%) | Medium (40-60%) |

| Key Technologies | AGV, AS/RS, WMS, MES | Sequencing systems, tugger trains, RFID | VLM, carousels, vision systems, dry storage | Cranes, heavy AGV, yard management |

| Quality Control | In-process inspection | Zero-defect, supplier audits | Vision inspection, counterfeit detection | Certification verification |

| Traceability | Batch and lot tracking | Serial number, VIN tracking | Component genealogy, serial tracking | Project allocation, asset tracking |

| Primary Challenge | Production schedule changes | Sequencing accuracy, model mix | Component obsolescence, ESD | Heavy material safety, project coordination |

| Investment Priority | MES integration, AGV | Sequencing automation, heavy handling | High-density storage, vision systems | Heavy-duty equipment, yard management |

Manufacturing

Automotive

Electronics

Industrial

Key Insights

Manufacturing warehouses serve as the backbone of production operations, providing just-in-time material delivery to assembly lines. The focus is on flexibility and tight integration with MES systems to respond rapidly to production schedule changes.

Automotive operations demand the highest precision with just-in-sequence delivery, where parts must arrive in exact assembly order. Heavy material handling and zero-defect quality requirements make this one of the most demanding warehouse environments.

Electronics warehousing manages the highest SKU complexity with tens of thousands of small components requiring ESD protection and humidity control. Component obsolescence and counterfeit prevention are critical challenges in this fast-paced industry.

Industrial operations handle the heaviest materials and equipment, often supporting project-based logistics with custom kitting and job site delivery. Hazmat compliance and specialized transport requirements add complexity to these B2B-focused operations.