Momentum Warehouse Execution System (WES): Real-Time Fulfillment Orchestration

⚡Quick Facts

Technology Performance Metrics

⭐Key Features

✨Benefits

🎯Applications

📝Detailed Information

Technology Overview

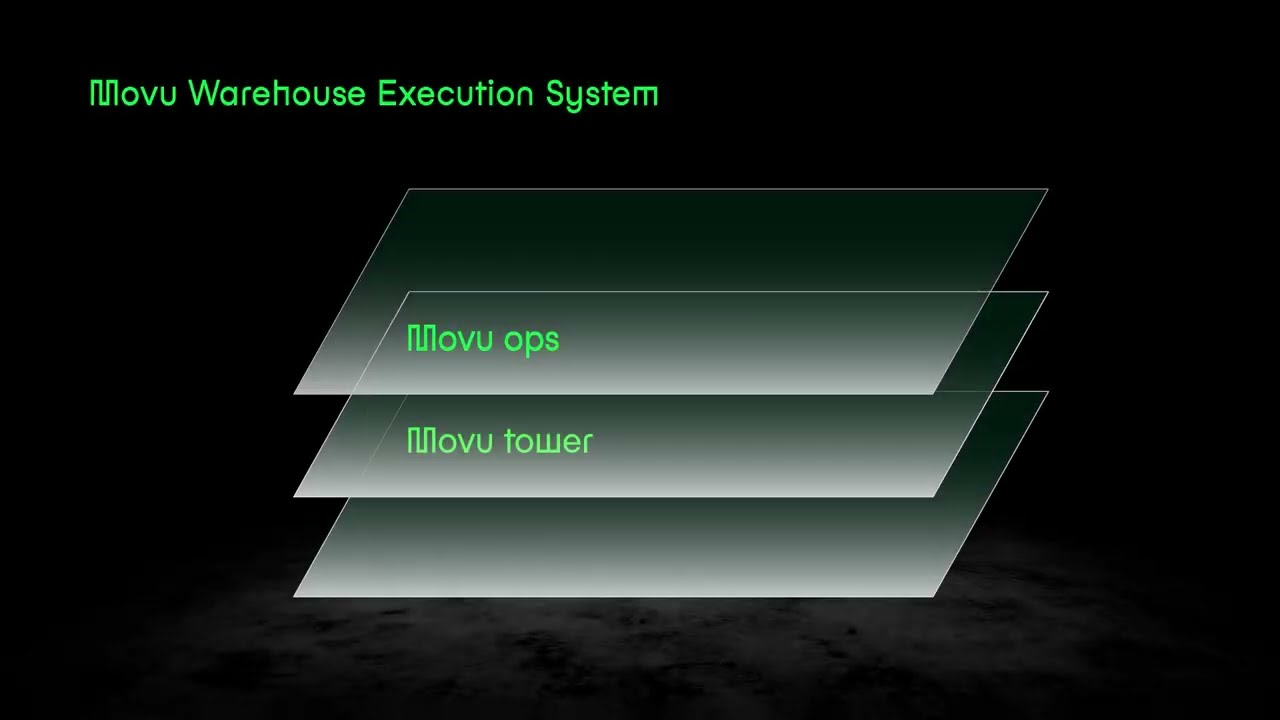

The Momentum Warehouse Execution System (WES) from Honeywell Intelligrated is a sophisticated software platform engineered to address the dynamic complexities of modern fulfillment, particularly in omnichannel and e-commerce environments. It moves beyond traditional Warehouse Management Systems (WMS) by acting as a real-time orchestration layer that sits between business systems (like ERP/WMS) and physical warehouse operations. Its core purpose is to simplify complex operations by seamlessly connecting orders, labor, and automated systems into synchronized workflows. Built on a unified codebase from the ground up, Momentum WES is designed to provide complete visibility and make automated decisions on the fly, transforming warehouse operations from a collection of partially connected, reactive processes into a cohesive, adaptive, and efficient fulfillment engine.

How It Works

Core Principles

Momentum WES operates on the principle of real-time, centralized orchestration. It ingests order demand from upstream systems and dynamically manages the execution of those orders across all available resources—people, robots, conveyors, sorters—based on real-time conditions on the warehouse floor. It uses algorithms to optimize flow, balance workloads, and prevent congestion.

Key Features & Capabilities

Real-Time Decision Making and Optimization: The system's standout capability is its ability to make automated decisions in real-time. It constantly optimizes order flow, rebalances workloads across zones, and adjusts to changes (like a surge in orders or a station going down) as they happen, preventing backups and congestion.

Unified Platform Architecture: Built as a single, integrated platform from a "clean sheet," it combines functionality that is often siloed—such as order management, automated picking/routing, and quality assurance—into one cohesive system. This eliminates integration gaps and provides a single source of truth.

"Configure to Need" Flexibility: The platform is designed with a flexible architecture that allows it to be configured to meet specific operational needs without requiring expensive and time-consuming custom code development. This enables adaptation as business requirements evolve.

Seamless Integration with Automation: Momentum WES is engineered to deeply integrate with Honeywell Intelligrated's material handling equipment (conveyors, sorters, AS/RS, etc.), creating a tightly coupled, intelligent system where software commands and physical execution are perfectly synchronized.

Advantages & Benefits

The primary benefit is providing the flexibility and speed required for complex, high-volume omnichannel fulfillment, enabling operations to meet demanding customer service promises. By orchestrating synchronous workflows, it eliminates the inefficiencies and delays caused by disconnected systems, leading to faster order cycle times. The system prevents costly congestion and order backups by intelligently controlling work release, ensuring items arrive at consolidation points exactly when needed. This results in maximized labor and equipment utilization and higher overall throughput. Ultimately, it provides the visibility and control needed to turn a chaotic warehouse into a consistently high-performing one, ensuring "a good day in the warehouse should be every day."

Implementation Considerations

Implementing Momentum WES represents a shift towards a highly integrated, software-driven operation. It requires a clear strategy for integration with existing Warehouse Management Systems and any third-party automation. The cultural and process change for operations staff moving from discrete tasks to a system-directed workflow can be significant and requires careful change management. While the "configure to need" architecture reduces customization, a detailed understanding of current and future operational flows is still required for optimal configuration. The full potential is often unlocked when deployed as part of Honeywell's broader Integrated Connected Distribution Center solution.

Use Cases & Applications

Ideal For

This system is ideal for large, complex distribution centers and fulfillment hubs that operate in fast-moving omnichannel or e-commerce environments, especially those struggling with synchronization issues between people and multiple automated systems.

Performance Metrics

The source emphasizes qualitative performance improvements: elimination of conveyor congestion and order delays, optimized order flow, and real-time responsiveness. Key metrics it influences include increased order throughput, reduced order cycle time, higher equipment and labor utilization rates, and improved on-time shipping performance. The ability to rebalance work dynamically is a direct contributor to overall system resilience and efficiency.

Conclusion

The Honeywell Intelligrated Momentum Warehouse Execution System represents a strategic evolution in warehouse control software. It is not merely a tool for tracking but an intelligent engine for real-time optimization and execution. For companies grappling with the volatility and complexity of modern fulfillment, investing in a WES like Momentum can be transformative. It provides the critical layer of coordination needed to harmonize people, processes, and automation, turning potential chaos into a reliable, high-speed operation. Its unified architecture and configurable nature make it a future-proof foundation for adapting to the ever-changing demands of the logistics industry, ensuring that peak performance becomes the daily standard.

📦Related Projects

Bee Sweet Citrus California Palletizing Facility

Bee Sweet Citrus implemented Honeywell Intelligrated's automated palletizing solution to handle diverse citrus packaging with 125 trucks daily from their 400,000 sq ft campus.

Dongfeng Motor R&D Center Smart Logistics Warehouse

A compact 470㎡ intelligent warehouse with 15-level high-density storage supporting 10,000+ SKUs for automotive R&D supply chain optimization.