Cantilever Racking Systems: Storage for Long, Bulky & Heavy Items

⚡Quick Facts

Technology Performance Metrics

⭐Key Features

✨Benefits

🎯Applications

📝Detailed Information

Technology Overview

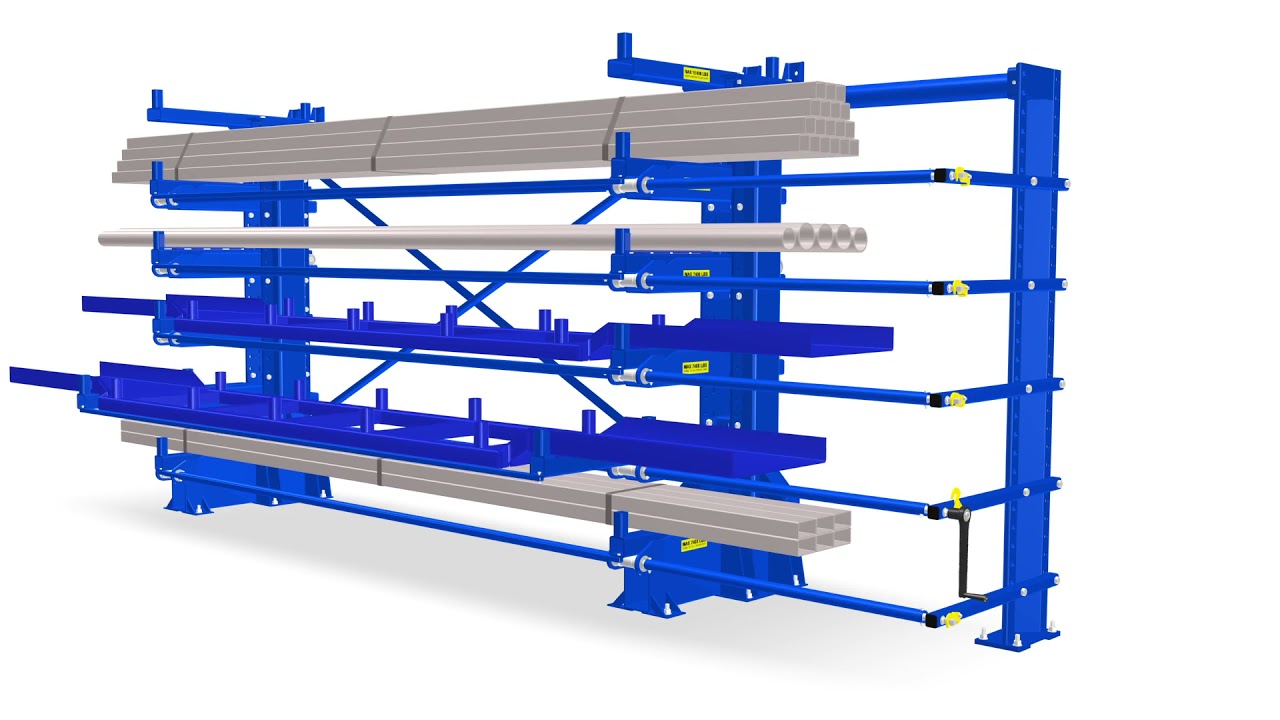

Cantilever racking systems are a specialized storage solution engineered to address the unique challenges of handling long, heavy, or awkwardly shaped inventory that cannot be efficiently stored on standard pallet racking. Characterized by their distinctive open-front design—lacking vertical front columns and horizontal beams at the load face—they provide unimpeded access along the entire length of the stored item. This design is indispensable in industries such as construction, manufacturing, lumber, and furniture, where products like pipes, bars, tubing, and panels are common. By maximizing vertical space and offering exceptional flexibility, cantilever racking transforms the storage of non-palletized, lengthy goods into an organized and space-efficient process.

How It Works

Core Principles

The system operates on a simple cantilever principle. Load-bearing arms extend horizontally from vertical columns (uprights). Items are placed directly onto these arms, with the load supported from below and the front completely clear for side loading.

Key Features & Capabilities

Open-Front Design is the defining feature, eliminating obstructions and allowing full-length side access to stored items. Adjustable Arms can be positioned at varying vertical intervals on the column to create custom storage levels for different product heights. Convertible Design allows single-sided racks (against a wall) to be easily converted to double-sided (freestanding aisle) configurations due to pre-punched columns. High Vertical Utilization makes efficient use of the building's clear height for storing lengthy items upright.

Advantages & Benefits

The primary advantage is unmatched accessibility for long/bulky items, drastically simplifying loading and unloading compared to wrestling items in and out of standard rack bays. The system offers high weight capacity and durability for heavy industrial loads. Its flexibility and ease of reconfiguration allow the storage layout to adapt quickly to changing inventory profiles. By storing items vertically, it maximizes cube utilization in facilities where floor space is limited. This specialization makes it an indispensable and efficient solution for its target inventory types.

Implementation Considerations

Cantilever racking is a specialized system not intended for standard palletized goods. Proper engineering and installation are critical, especially for tall systems or those storing very heavy loads, to ensure stability. Load placement and balancing on the arms must be managed to prevent tipping. The cost per storage position is typically higher than for standard pallet racking due to its heavy-duty construction and specialized design.

Use Cases & Applications

Ideal For

This system is ideal for any warehouse, distribution center, or manufacturing facility that primarily handles inventory that is long, bulky, heavy, and not easily palletized.

Conclusion

Cantilever racking systems fill a critical niche in the material storage landscape. For businesses dealing with long, heavy, or irregularly shaped items, they offer a solution that standard racking cannot match. By providing clear access, heavy-duty support, and flexible configuration, they optimize storage operations, improve safety, and make efficient use of valuable warehouse space. While a specialized investment, for the industries that need it, cantilever racking is not just an option but an essential tool for operational efficiency and organized inventory management.