SSI LOGIMAT Vertical Lift Module (VLM): High-Density Small Parts Storage

⚡Quick Facts

Technology Performance Metrics

⭐Key Features

✨Benefits

🎯Applications

📝Detailed Information

Technology Overview

The SSI LOGIMAT Vertical Lift Module (VLM) is an automated storage and retrieval system specifically engineered for the high-density, efficient handling of small parts and components. It addresses the critical challenge of space utilization in warehouses and production facilities by storing items vertically in a compact footprint, rather than spreading them out horizontally. The system consists of a series of trays that are stored within a tall, enclosed column and are delivered to an ergonomic access window by a fully automated inserter/extractor mechanism. With scalability up to 78 feet tall and an impressive load capacity, it is designed as a robust, long-lasting solution. A key advantage is its seamless integration with enterprise resource planning (ERP) systems like SAP and Oracle, enabling real-time inventory management and automated order processing. This makes the LOGIMAT VLM a comprehensive solution for optimizing operations, reducing errors, and minimizing the physical footprint required for parts storage across diverse industries.

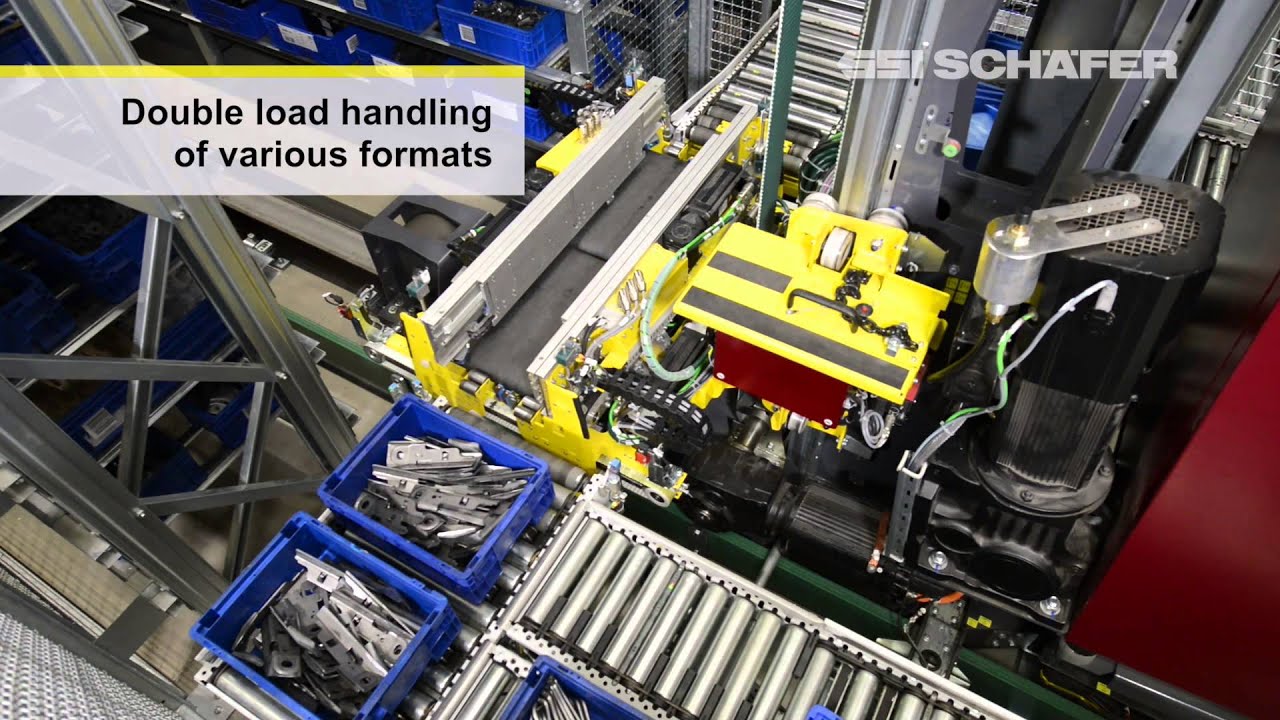

How It Works

Core Principles

The VLM operates on the principle of vertical, automated density. It uses a computer-controlled extractor mechanism that moves vertically within a closed column to retrieve specific storage trays from any height and deliver them to a fixed, ergonomic pick window. This creates a "goods-to-person" delivery system where the parts come to the operator, eliminating walking and searching.

Key Features & Capabilities

High Scalability and Load Capacity are standout features. The ability to reach heights of up to 78 feet allows the system to make extreme use of vertical air space. Coupled with a load capacity of up to 66 U.S. tons, it can store a massive quantity of heavy small parts, such as metal components or dense pharmaceuticals.

Seamless ERP/WMS Integration is a critical capability. The system is designed to connect directly with major ERP platforms like SAP and Oracle, enabling bidirectional data flow. This allows for automated transaction recording, real-time inventory visibility, and direct order-driven picking, integrating the VLM deeply into the company's digital workflow.

Customizable Tray Configurations provide application flexibility. Trays can be configured with dividers, bins, or compartments of various sizes to perfectly match the specific dimensions and organization needs of the stored items, from tiny screws to large catalogs or tool kits.

Advantages & Benefits

The most significant advantage is extreme space savings and reduced real estate costs. By storing inventory vertically in a footprint often less than 50 square feet, the VLM can free up vast amounts of floor space for other value-adding activities or allow operations to condense into a smaller, less expensive facility.

It delivers dramatic improvements in picking accuracy and efficiency. The "goods-to-person" principle eliminates travel and search time, while the guided picking at the window ensures the right item and quantity are selected, achieving virtually error-free operations and boosting pick rates by significant margins.

The system enhances inventory security and control. The enclosed structure provides controlled access, reducing loss and misplacement. Combined with real-time ERP integration, it provides perfect inventory accuracy, supporting just-in-time processes and reducing carrying costs.

Implementation Considerations

Adequate ceiling height is a prerequisite to leverage the full scalability (up to 78 ft). Retrofitting into existing buildings may be limited by structural clearances.

Careful tray and slotting design is essential for optimal performance. The upfront analysis of part dimensions, weights, and picking frequencies is required to design the tray layouts and assign storage locations effectively.

While the picking process is highly efficient, it is typically a single-order or single-task station. For very high-volume picking, multiple VLMs or complementary systems may be needed to avoid the VLM itself becoming a bottleneck.

Use Cases & Applications

Ideal For

This system is ideal for manufacturing plants (for kitting and line-side supply), maintenance departments (MRO), pharmaceutical warehouses, electronics assembly, and any service or distribution center that manages a vast array of small parts and needs to optimize space and picking accuracy.

Performance Metrics

Key performance specifications include:

- Maximum Height: Up to 78 feet.

- Load Capacity: Up to 66 U.S. tons (machine capacity).

- Key Performance Attribute: Secure and virtually error-free picking.

- Integration: Seamless integration with SAP, Oracle, and other ERP systems.

Conclusion

The SSI LOGIMAT Vertical Lift Module is a powerful and proven solution for conquering the challenges of small parts storage. Its strength lies in transforming inefficient, space-consuming shelving into a compact, automated, and intelligent vertical warehouse. For operations burdened by sprawling parts storage, inaccurate picking, and high real estate costs, the VLM offers a compelling path to radical improvement. Success requires careful planning regarding facility fit, tray design, and system integration. However, the investment pays off in reclaimed floor space, dramatic gains in picker productivity and accuracy, and tighter inventory control, making it a cornerstone technology for efficient small parts management in the modern industrial and logistics landscape.

📦Related Projects

MPE Plastics Turin Automotive Warehouse

MPE implemented SSI Schaefer's mobile racking and AGV solution to maximize storage capacity and meet automotive industry reliability requirements.

ASKO Oslofjord Automated Distribution Center

ASKO proactively addressed capacity constraints with SSI Schaefer's automated DC solution, achieving 80-90% process automation with strong sustainability focus.

Imbach Logistik - Luzern Logistics Center Automation

Swiss company Imbach Logistik built the Luzern Logistics Center with SSI Schaefer's automation solution, offering 130,000 container slots, 6,000+ pallet positions, and 116 pallets/hour picking rate to grow efficiently on limited space.