OCS 500 Overhead Conveyor System: High-Capacity Friction Drive

⚡Quick Facts

Technology Performance Metrics

⭐Key Features

✨Benefits

🎯Applications

📝Detailed Information

Technology Overview

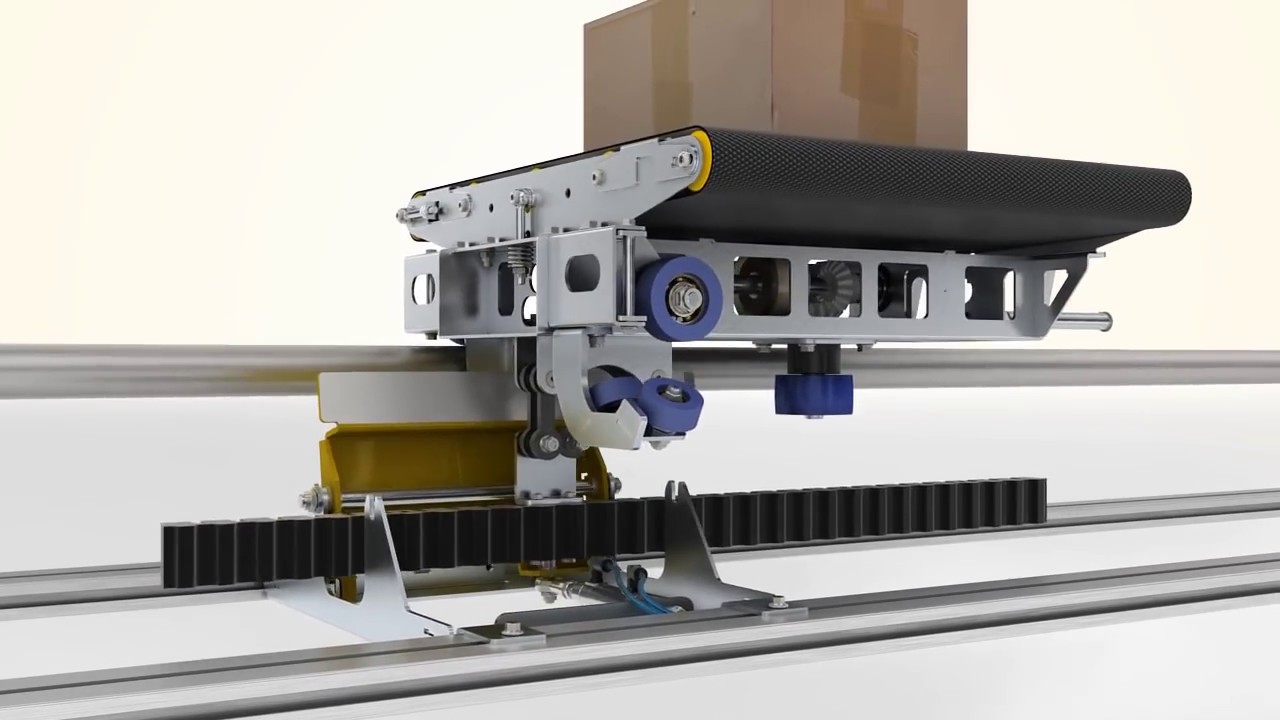

The OCS 500 represents a specialized overhead conveyor system engineered for robust material handling in industrial production environments. Designed to manage significant loads, it utilizes a unique friction drive principle to move trolleys along an overhead track. This system is focused on providing a clean, quiet, and highly controllable method of transporting goods through a facility, integrating directly with production flows. Its modularity and intelligent control features make it suitable for complex layouts requiring routing flexibility, speed variation, and in-process buffering to optimize manufacturing efficiency.

How It Works

Core Principles

The system operates on a patented friction drive principle. A centrally powered rotating tube runs along the track. Each trolley is equipped with angled wheels that contact this tube. The rotation of the tube is transmitted through these wheels, creating friction that propels the trolley forward, eliminating the need for a traditional chain.

Key Features & Capabilities

The high payload capacity of 500 kg per meter of track allows the system to handle heavy components or multiple items simultaneously, making it suitable for automotive or heavy assembly. Its variable drive speed from 1 to 30 meters per minute provides precise control over line pacing to match different process cycle times. The core innovation is the patented, quiet, clean, and oil-free friction drive system, which reduces noise pollution, maintenance (no lubrication), and avoids contamination—ideal for sensitive environments.

The modular design with driven curves and switches offers exceptional layout flexibility, enabling the track to navigate tight spaces and create complex routing networks within a facility. Integrated identification and sensor control enables traceability and real-time management of production flows and buffer quantities. Finally, the built-in Power & Free buffering capability is critical for smoothing production, allowing trolleys to accumulate directly on the powered track or in dedicated buffer areas to prevent downstream bottlenecks.

Advantages & Benefits

The system creates silent and clean systems with no lubrication required, leading to a better working environment and lower long-term maintenance costs. Its modular nature contributes to effective installation, as components can be pre-configured and adapted to existing building constraints. It enhances production flow balance with versatile buffering technology, minimizing downtime at stations and optimizing overall equipment effectiveness (OEE). The use of energy-efficient motors with soft start/stop capabilities further reduces energy consumption and mechanical stress on the system.

Implementation Considerations

Key considerations include the fact that the incline capability is dependent on the payload weight; heavier loads will reduce the maximum effective incline angle, potentially requiring additional vertical conveyors for significant elevation changes. The drive unit length is limited, necessitating careful planning for longer conveyor runs which will require additional motors and drive sections. Successful system integration requires planning for identification, sensor placement, and buffer zones to fully leverage the control and buffering capabilities.

Use Cases & Applications

Ideal For

The OCS 500 is ideal for complex, high-capacity assembly and production lines where flexible routing, controlled pacing, and in-line buffering are essential to maintain flow and balance, such as in automotive manufacturing or large appliance assembly.

Performance Metrics

The system offers configurable speed (1-30 m/min) and high linear payload capacity (500 kg/m). The integration of Power & Free buffering and intelligent control via RFID/sensors directly contributes to increased line efficiency and reduced waiting times. The quiet, oil-free operation lowers the total cost of ownership related to maintenance and workplace compliance.

Conclusion

The OCS 500 overhead conveyor system is a sophisticated solution for heavy-duty, intelligent material transport in modern manufacturing. By combining a high-capacity friction drive with modular flexibility, intelligent control, and integrated buffering, it addresses key challenges of production flow balancing, space utilization, and operational cleanliness. It is a strong candidate for operations looking to enhance throughput, traceability, and flexibility in their overhead material handling processes.